HRB500 anti-seismic reinforcing steel bar and production method

An earthquake-resistant steel bar and a production method technology, applied in the field of iron and steel smelting, can solve the problems such as the reduction of the steel bar ratio and the failure of the steel bar to meet the high-strength-to-yield ratio, so as to reduce the precipitation strengthening and fine-grain strengthening, avoid excessive grain refinement, and increase the solid solution. The effect of the strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

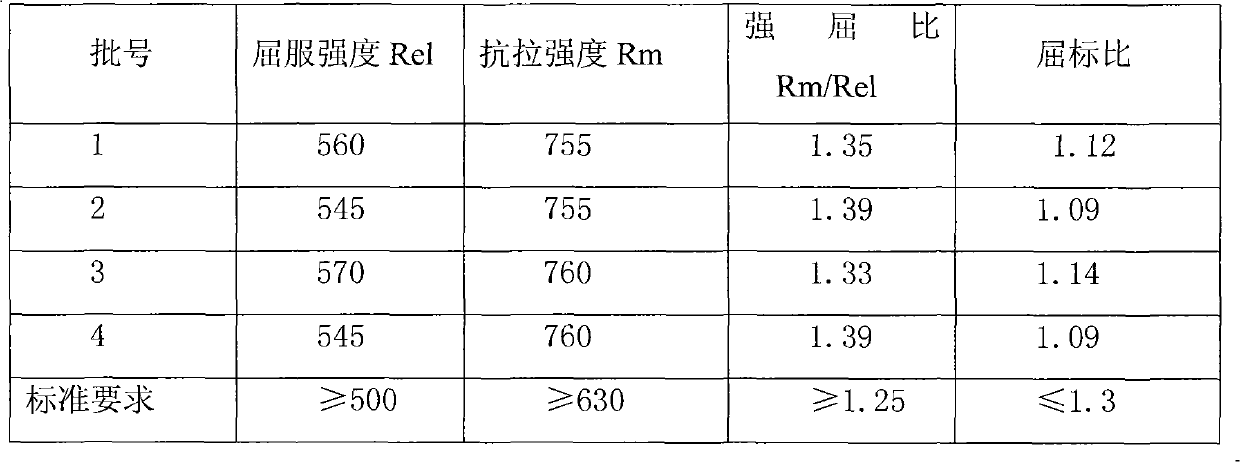

[0012] In the prior art, in order to improve the strength of steel bars, most of the methods adopted are achieved by microalloying or controlled rolling and controlled cooling to refine grains. However, with the further refinement of the grains, the increase in the yield strength of the steel bar is greater than the tensile strength, which leads to the reduction of the Rm / Rel ratio of the steel bar, and the steel cannot meet the seismic performance requirements. Therefore, while increasing the yield strength of the steel bar, how to increase its tensile strength has become the key to solving the problem.

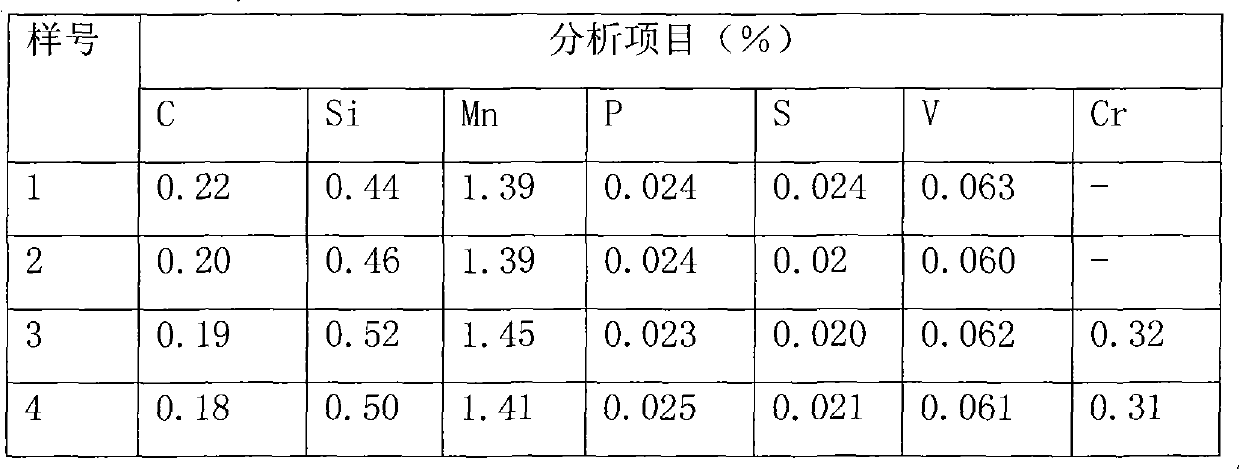

[0013] The invention adopts Cr and V composite microalloying, and adding a small amount of Cr and an appropriate amount of Cr and V to the steel bar is the key technology. Cr is a carbide forming element. Cr can be partially dissolved in austenite to strengthen the matrix without reducing toughness, delay the transformation of undercooled austenite, and increase the hardenabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com