Sewing device with an upper thread tension adjustment device

A tension adjustment and sewing machine technology, applied in the field of sewing machines, can solve problems such as high cost, complex structure, and difficult fine-tuning, and achieve the effect of easy sewing and wide tension adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

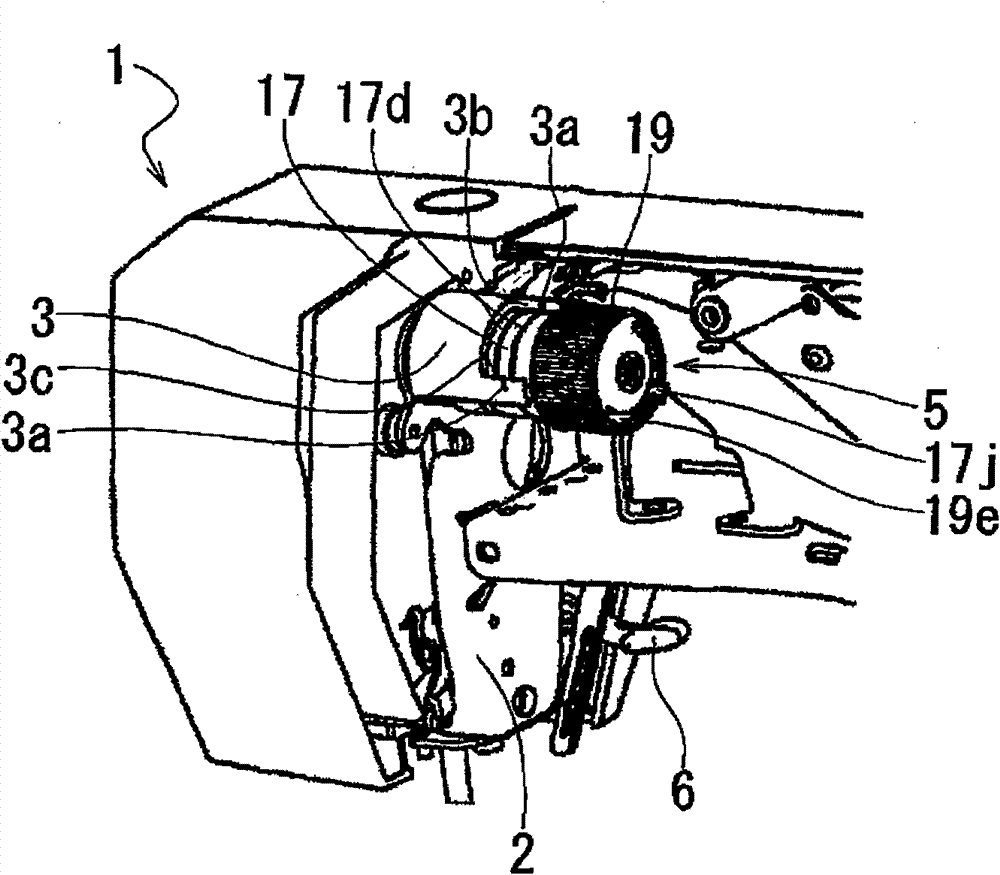

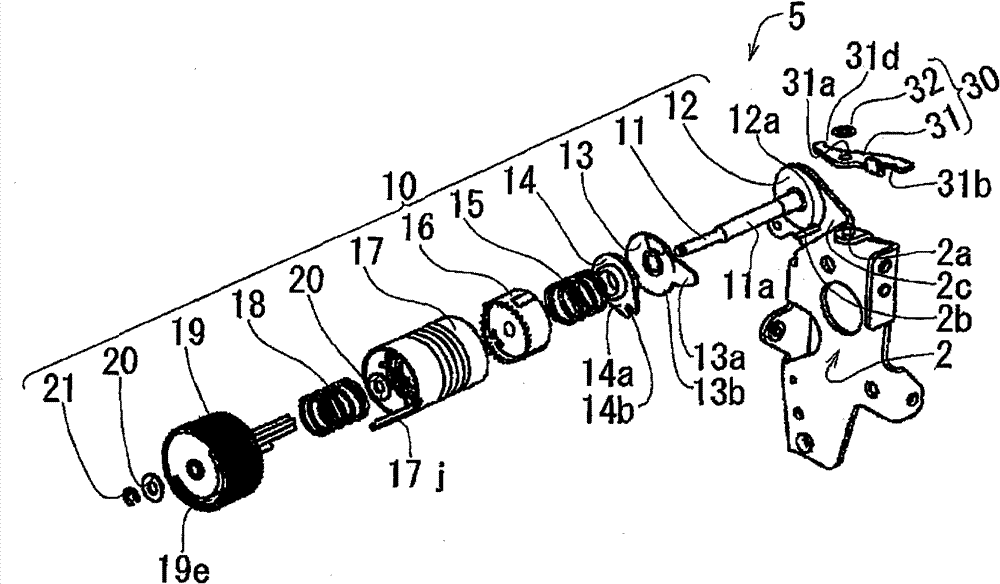

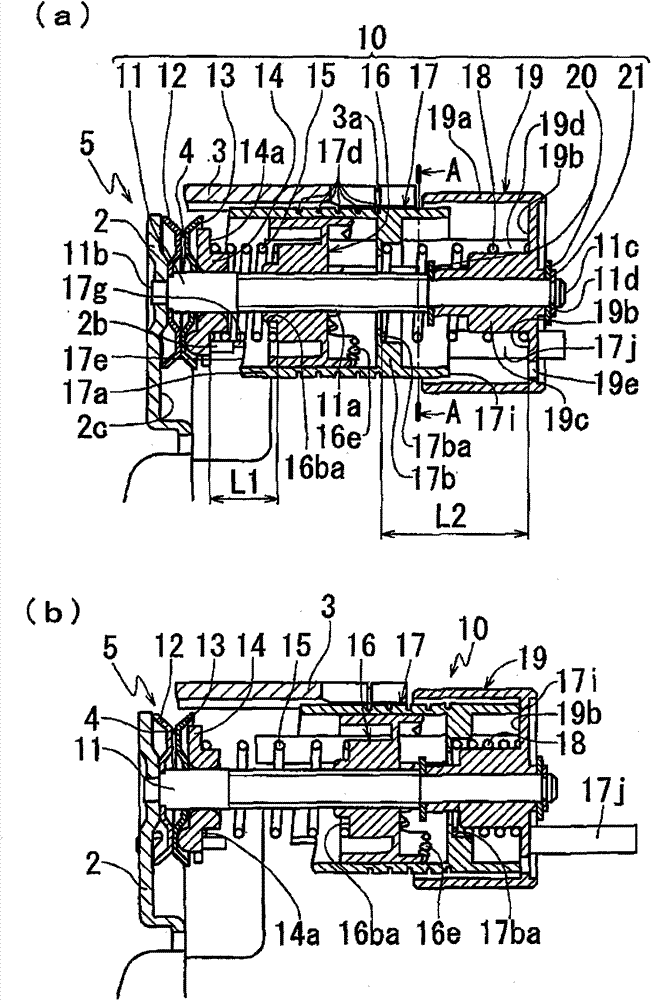

[0070] figure 1 A perspective view showing the vicinity of the thread tension dial of a sewing machine having the needle thread tension adjusting device of this embodiment, figure 2 express figure 1 An exploded perspective view of the needle thread tension adjustment device shown. Such as figure 1 As shown, the sewing machine 1 of the present embodiment has an upper thread tension adjustment device 5, and the shaft 11 of the upper thread tension adjustment device 5 ( figure 2 , image 3 ) is fixed on the machine base 2 of the sewing machine 1. Turn the thread tension dial 19 of the upper thread tension adjustment device 5 to figure 1 When the upper or lower direction of the upper thread tension adjustment device 5 is rotated, the tension display part 17 of the upper thread tension adjustment device 5 is proportional to the rotation angle of the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com