Compound mud-rock flow discharge and guide trough

A technology for drainage channel and debris flow, which is applied in water conservancy projects, artificial waterways, embankments, etc., can solve the problems of single type of debris flow drainage channel and low land utilization rate, so as to improve land utilization rate, alleviate human-land conflict, The effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

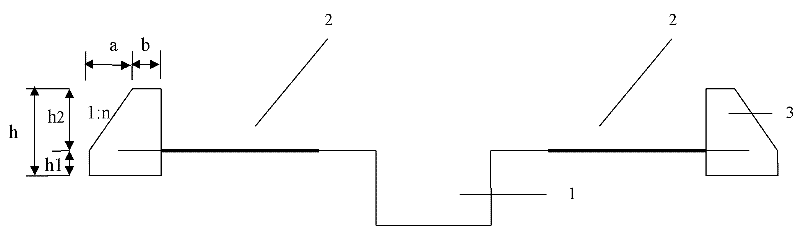

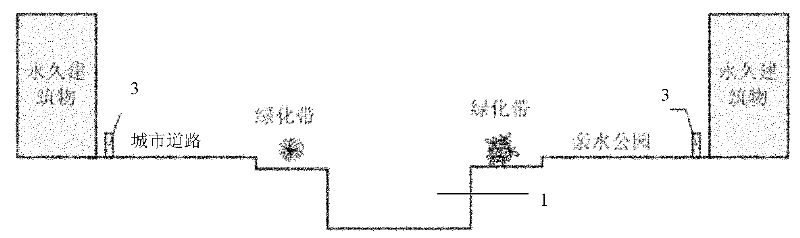

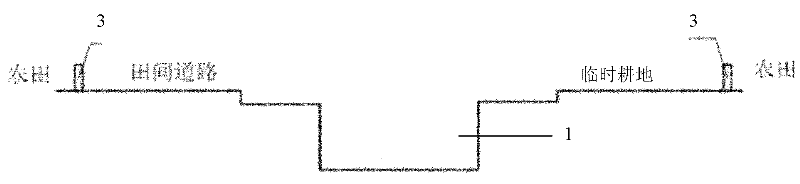

[0026] Such as figure 1 , figure 2 , image 3 Shown. The drainage area of a debris flow is 24.1km 2 The slope of the accumulation fan is 9.0%. On the 2500m long debris flow accumulation fan, build the compound debris flow drainage channel. The compound debris flow drainage channel includes a drainage channel main channel 1 for draining debris fluid under the design standard, and a drainage channel buffer zone 2 for draining debris fluid that exceeds the design standard; the drainage channel buffer zone 2 is located A gravity retaining wall 3 is provided on both sides of the main groove 1 of the row guide groove, and the boundary of the buffer area 2 of the row guide groove. Because the protection object is particularly important, the design standard of the main channel 1 of the drainage channel is designed according to the once-in-50-year event. The maximum scale of the entire compound debris flow drainage channel is once in 200 years (that is, the maximum discharge scale ...

Embodiment 2

[0030] Such as figure 1 , image 3 Shown. The drainage area of a debris flow is 14.1km 2 , The slope of the accumulation fan is 7.5%. In order to protect the railways and highways at the mouth of the ditch, the compound debris flow drainage channel was built on the 2000m long debris flow accumulation fan. The compound debris flow drainage channel includes a drainage channel main channel 1 for draining debris fluid under the design standard, and a drainage channel buffer zone 2 for draining debris fluid that exceeds the design standard; the drainage channel buffer zone 2 is located A gravity retaining wall 3 is provided on both sides of the main groove 1 of the row guide groove, and the boundary of the buffer area 2 of the row guide groove. The design standard of the main channel 1 of the drainage channel is designed according to the once-in-20-year event. The maximum debris flow standard for the entire compound debris flow drainage channel is once in 100 years (that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com