Surface temperature detection system for rotation part in high-temperature high-pressure container

A detection system, high temperature and high pressure technology, applied in the direction of radiation pyrometry, instruments, measuring devices, etc., can solve the problems of low temperature, large influence of emissivity, high temperature parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

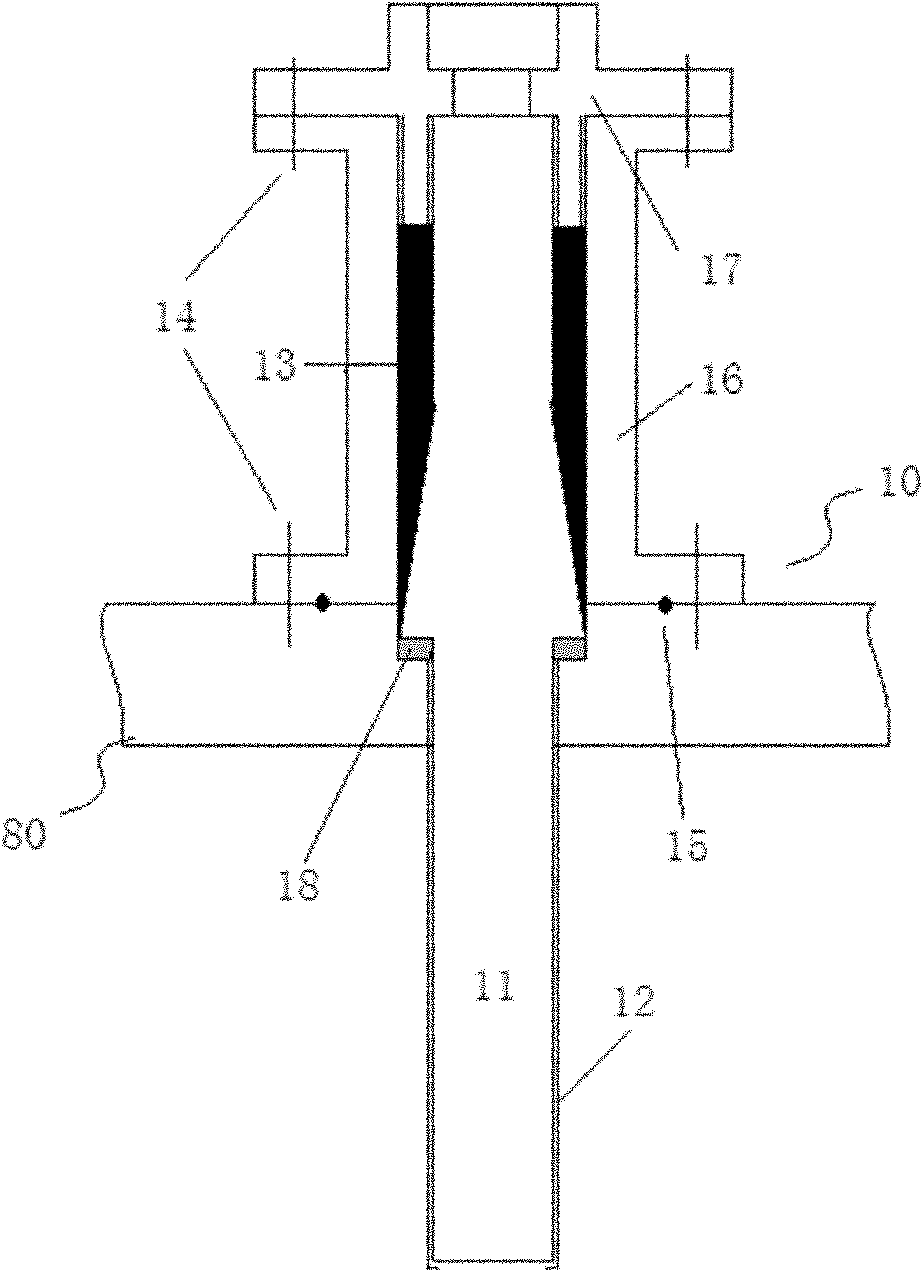

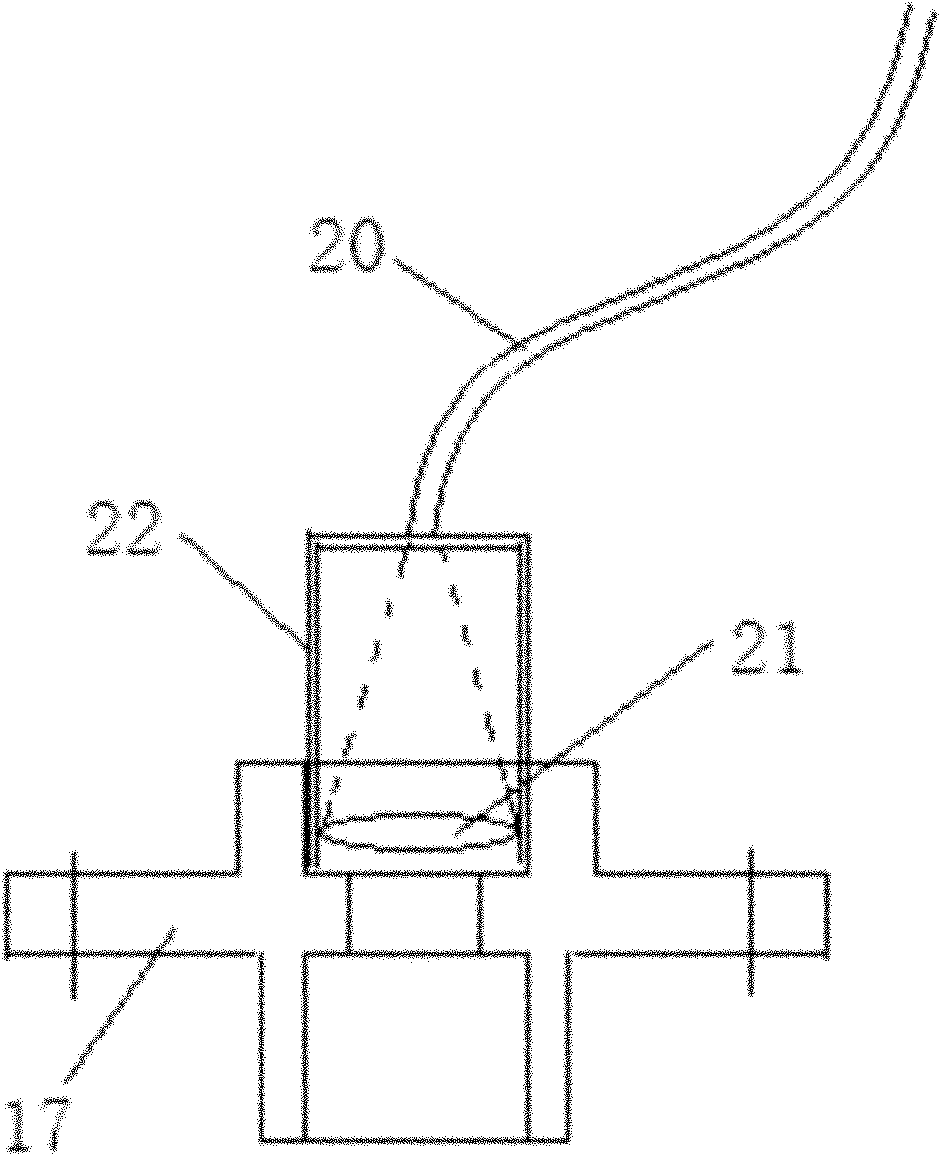

[0040] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0041] 1. Overall

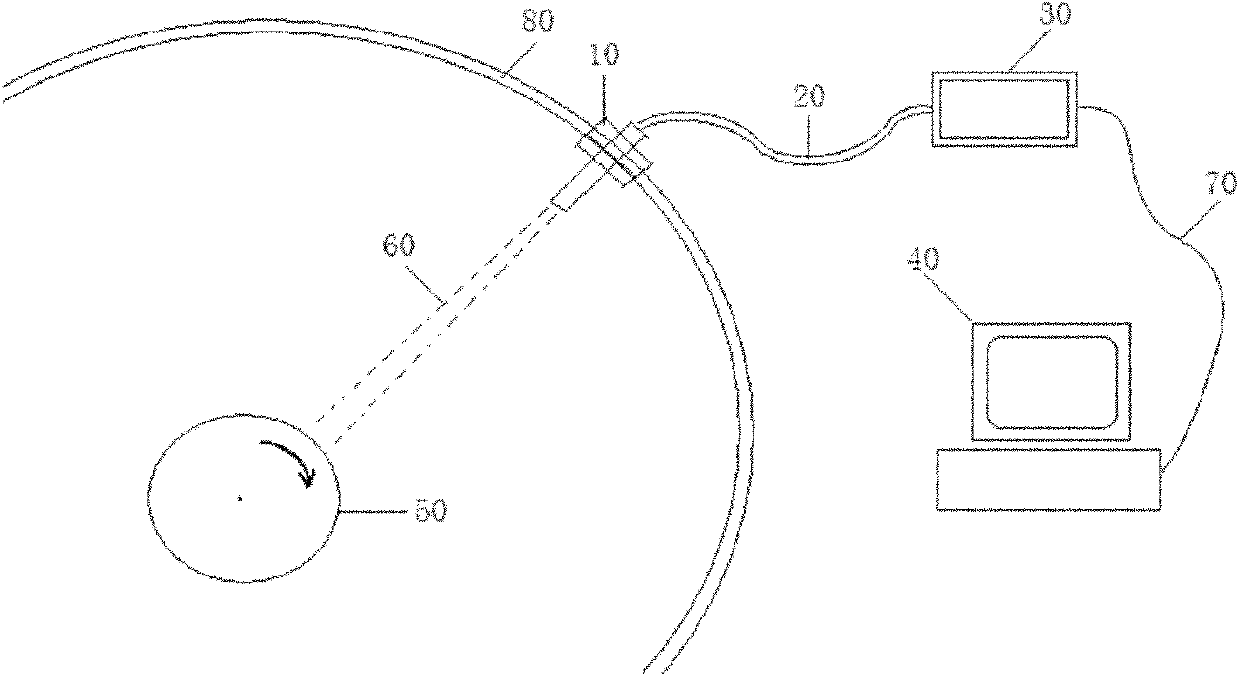

[0042] like figure 1 , the present invention includes the cylinder wall 80 of the pressure vessel to be tested and the rotating body 50 inside it;

[0043] An infrared window and sealing interface assembly 10, an infrared high-temperature optical fiber 20, an infrared temperature measurement module 30, a computer 40 and a signal cable 70 are provided;

[0044] An infrared window and sealing interface assembly 10 is connected to the cylinder wall 80 of the pressure vessel, and the infrared window and sealing interface assembly 10, the infrared high-temperature optical fiber 20, the infrared temperature measuring module 30, the signal cable 70 and the computer 40 are sequentially connected;

[0045] The infrared window and sealing interface assembly 10 is spatially opposite to the rotating body 50 through the infrared radiation optical path 60 .

[0046] 2. Function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com