Method for determining wind turbine blade structure based on finite difference method

A technology of wind turbine blades and finite difference method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as long design cycle and high requirements for design experience, so as to simplify design complexity and ensure Aerodynamic efficiency and structural strength, the effect of realizing lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

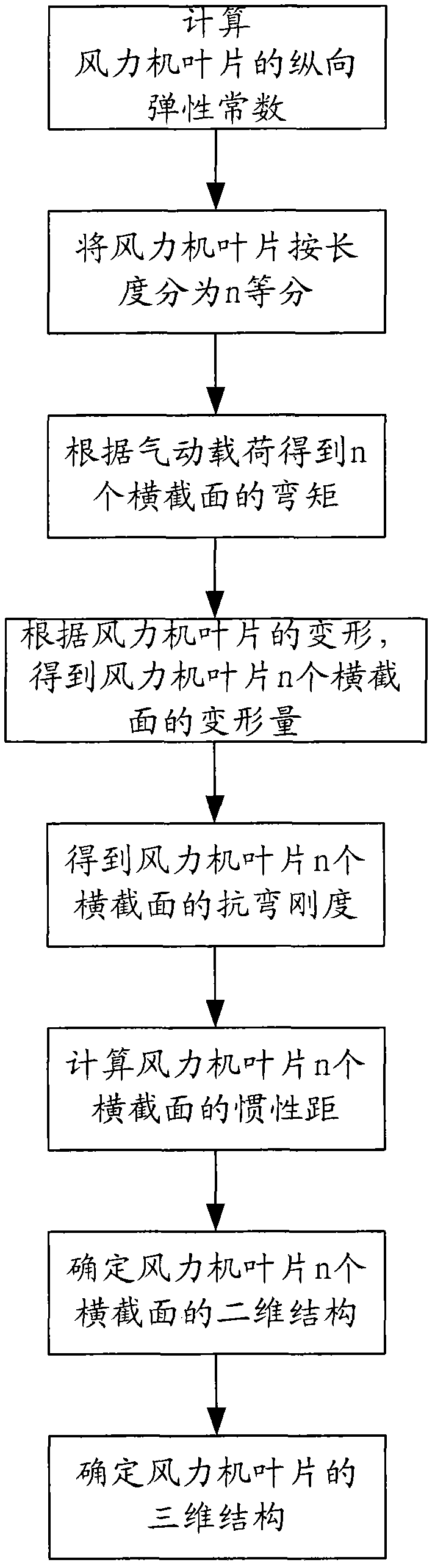

[0030] The present invention as figure 1 shown in the following steps:

[0031] 1. According to the given layering method of the wind turbine blade, the longitudinal elastic constant E of the wind turbine blade is obtained by using the blanket curve method.

[0032] The wind turbine blade is a composite material structure. First, determine a lay-up form during design. For example, compare the traditional 0° / 90° / ±45° with the [60 / 20 / 20] lay-up method, and calculate it according to the blanket curve method. The longitudinal elastic constant E of the laminate is obtained.

[0033] For the principle of the blanket curve method, see: Wang Yaoxian, "Composite Material Structure Design", Chemical Industry Press, September 2001.

[0034] 2. Divide the blade of the wind turbine into n equal parts according to the length, and obtain n cross-sections, each of which has a length of h.

[0035] For large megawatt wind turbine blades, in order to make the design more reasonable, n is gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com