Elastic knurling tool of robot

A robot and elastic technology, applied in the field of robot elastic hemming tools, can solve the problems of high cost, complex structure, unfavorable universal application, etc., and achieve the effect of easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

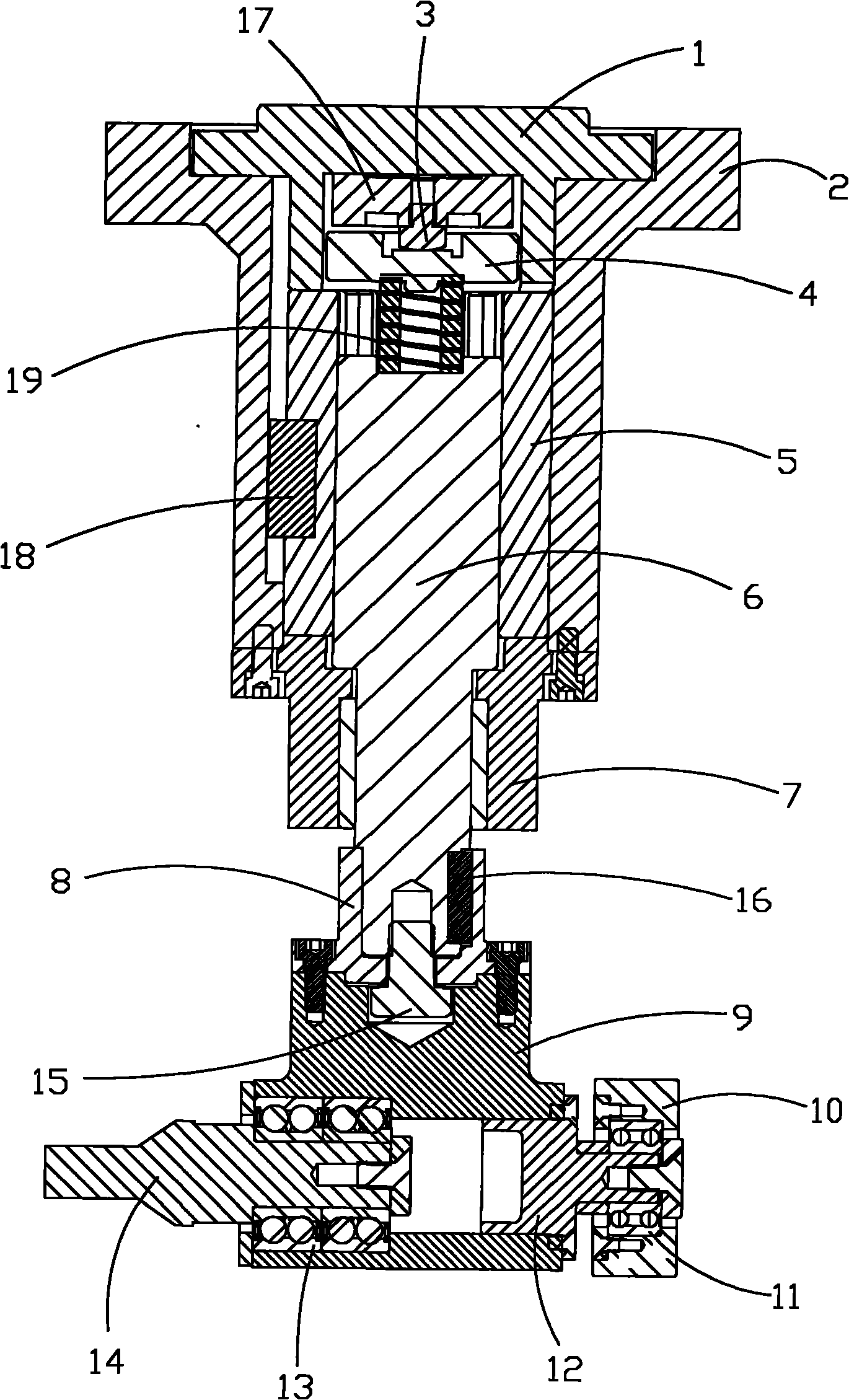

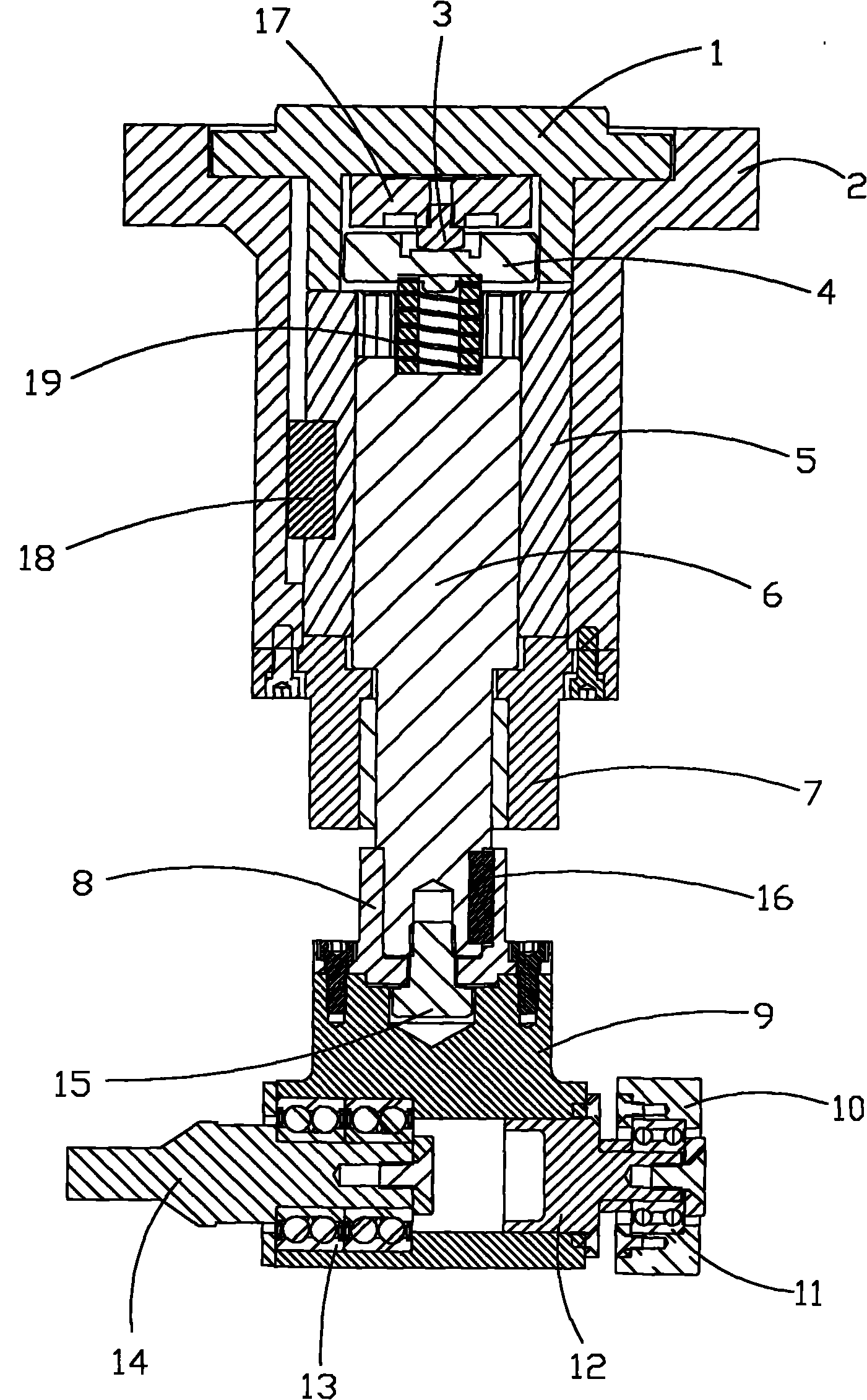

[0016] see figure 1 In this embodiment, the connection between the cover plate flange 1 and the sleeve 2 is set for bolt consolidation; the pressure sensor 17 is fixed on the cover plate flange 1 by bolts, and the sensor pressure head 3 is screwed to the pressure sensor 17 At the bottom, the upper end of the compression spring 19 pushes the spring compression block 4 against the sensor pressure head 3, and the lower end of the compression spring 19 is against the top of the spline shaft 6;

[0017] The roller mounting block 9 is set, and the large-diameter roller 10 and the small-diameter roller 14 are respectively installed on both sides of the end of the roller mounting block 9; the roller mounting block 9 is connected with the spline shaft 6 through the connecting block 8, and the spline shaft 16 restricts the mutual rotation between the roller mounting block 9 and the spline shaft 6; the spline sleeve 5 restricts the rotation with the sleeve 2 through the spline sleeve fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com