Sucker assembler

An assembler and straw technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency and low efficiency of manual assembly work, and achieve fast installation speed, improve work efficiency, and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

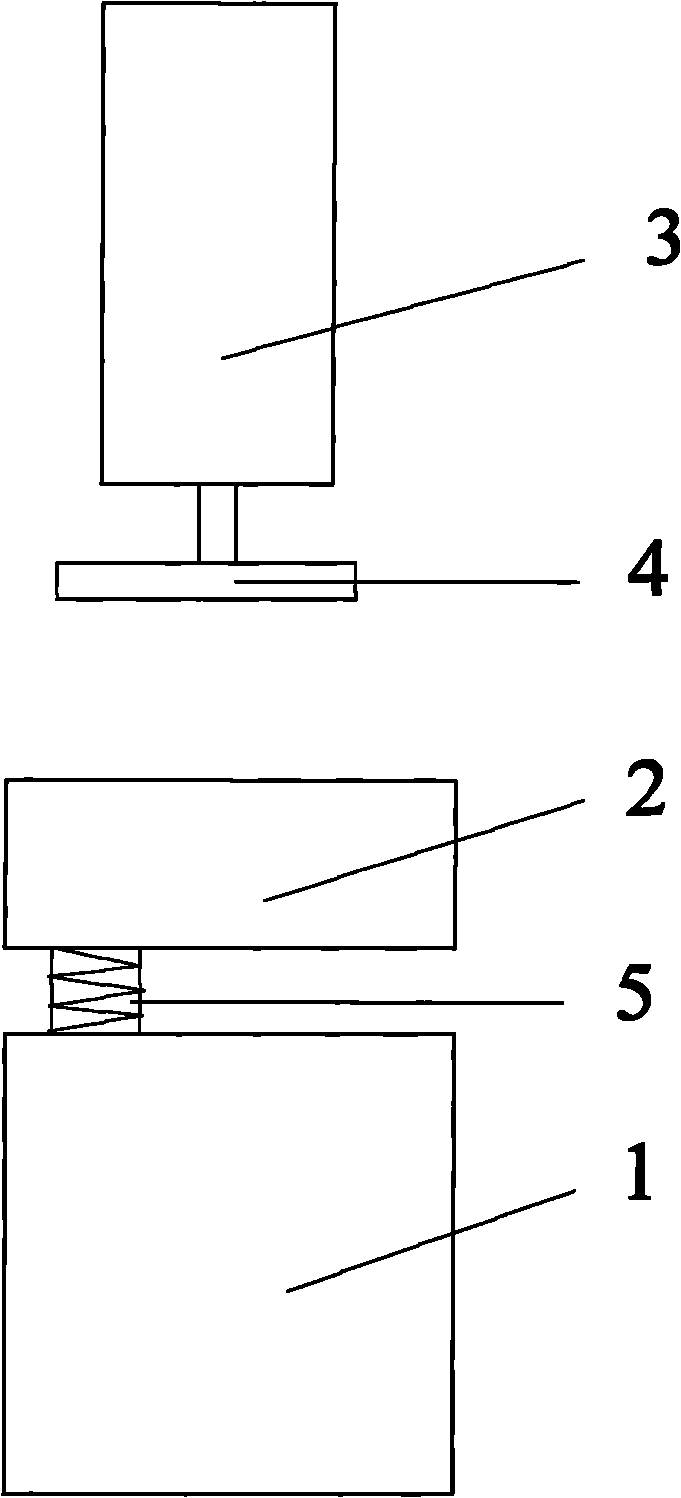

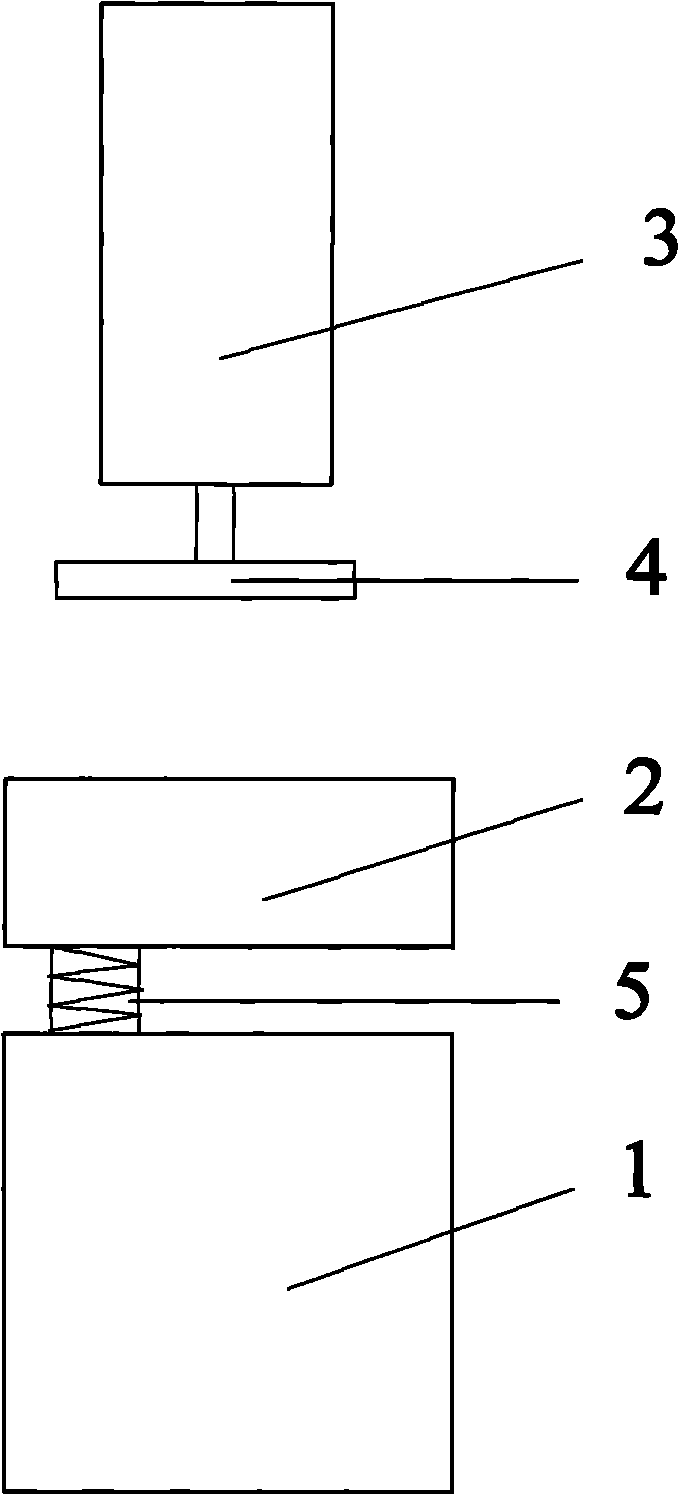

[0018] A straw assembler, its structure is as figure 1 As shown, the straw assembler includes a base 1, a cover 2, a cylinder 3, a pressure plate 4 and a spring 5, the base 1 is set at the bottom of the assembler, a straw is fixed on the base 1, and the cover 2 is set on the upper part of the base 1 , The cover base 2 is provided with a bottle cap, the cylinder 3 is located on the upper part of the cover base 2, the lower part of the cylinder 3 is provided with a horizontal pressure plate 4, and a spring 5 is provided between the base 1 and the cover base 2. When using, take the following steps:

[0019] (1) Position and install the suction pipe on the base 1;

[0020] (2) The bottle cap is installed on the cover seat 2;

[0021] (3) The base 1 and the cover 2 are separated by a certain distance through the action of the spring 3;

[0022] (4) Push the pressing plate 5 to press down by the pneumatic action of the cylinder 4;

[0023] (5) Pressing plate 5 touches the bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com