Adjustable spring braking air chamber

A spring brake air chamber, adjustable technology, applied in the direction of the brake, brake transmission device, reservoir layout, etc., can solve the problems that the brake deviation cannot be eliminated, the brake shoe pressure adjustment part is not designed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

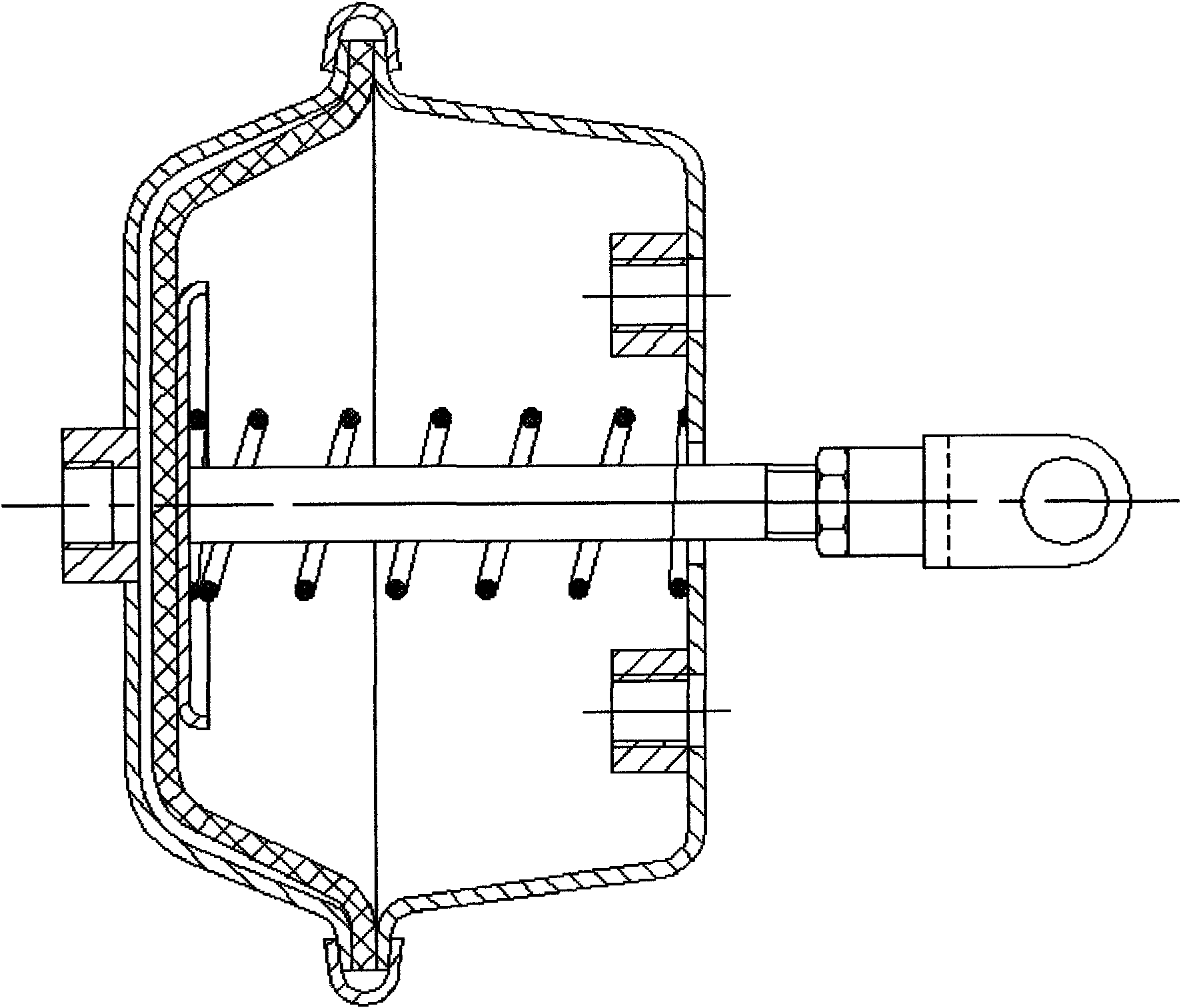

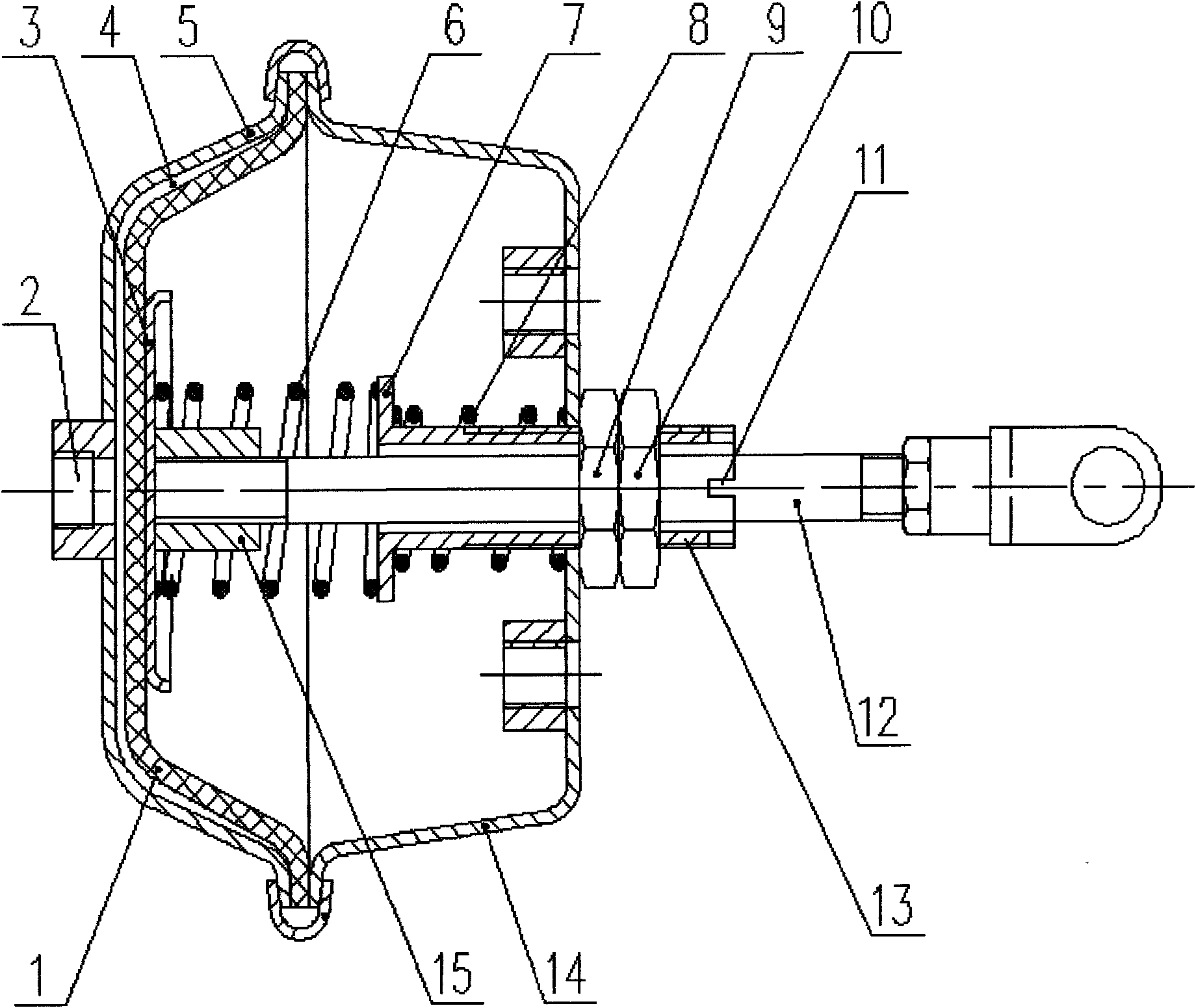

[0014] The accompanying drawings have shown the structure of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

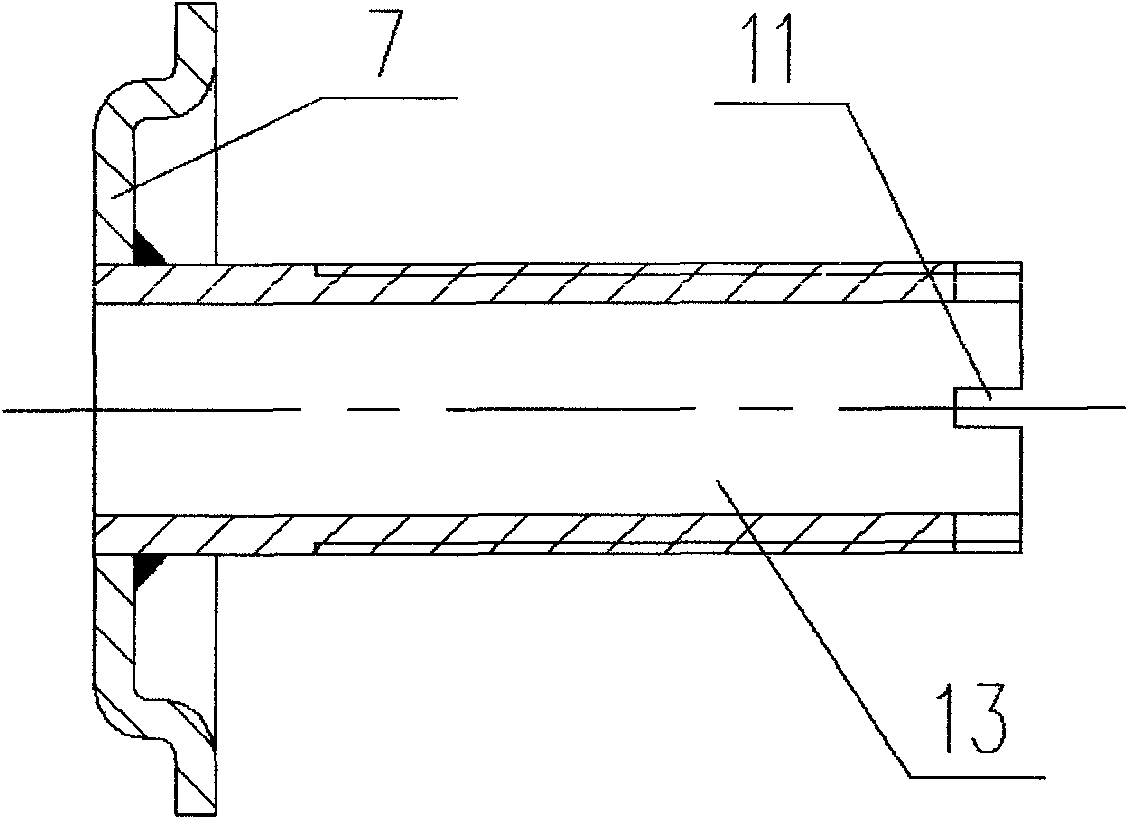

[0015] The present invention divides the return spring in the ordinary spring air chamber into two springs, front and rear, as figure 2 Shown front end is adjustment spring 8, and its one end withstands on the air chamber front shell 14, and the other end withstands the front of the base 7 of moving sliding sleeve 13. The rear end is a return spring 6, one end of which is pushed against the push rod base 3, and the other end is pushed against the back of the base 7 of the moving sliding sleeve 13. The elastic force of the adjustment spring 8 is greater than the elastic force of the return spring 6 . The moving sliding sleeve 13 is sleeved on the air chamber mandrel 12 and can move forward and backward. The front end of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com