Gas pipeline joint

A technology for gas pipelines and connecting pipes, which is applied in the directions of pipes/pipe joints/fittings, sealing surface connections, passing elements, etc., which can solve the problems of extremely high sealing and reliability requirements, complicated structure of pipe joints, and low safety and reliability. , to achieve the effect of low cost, good sealing effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

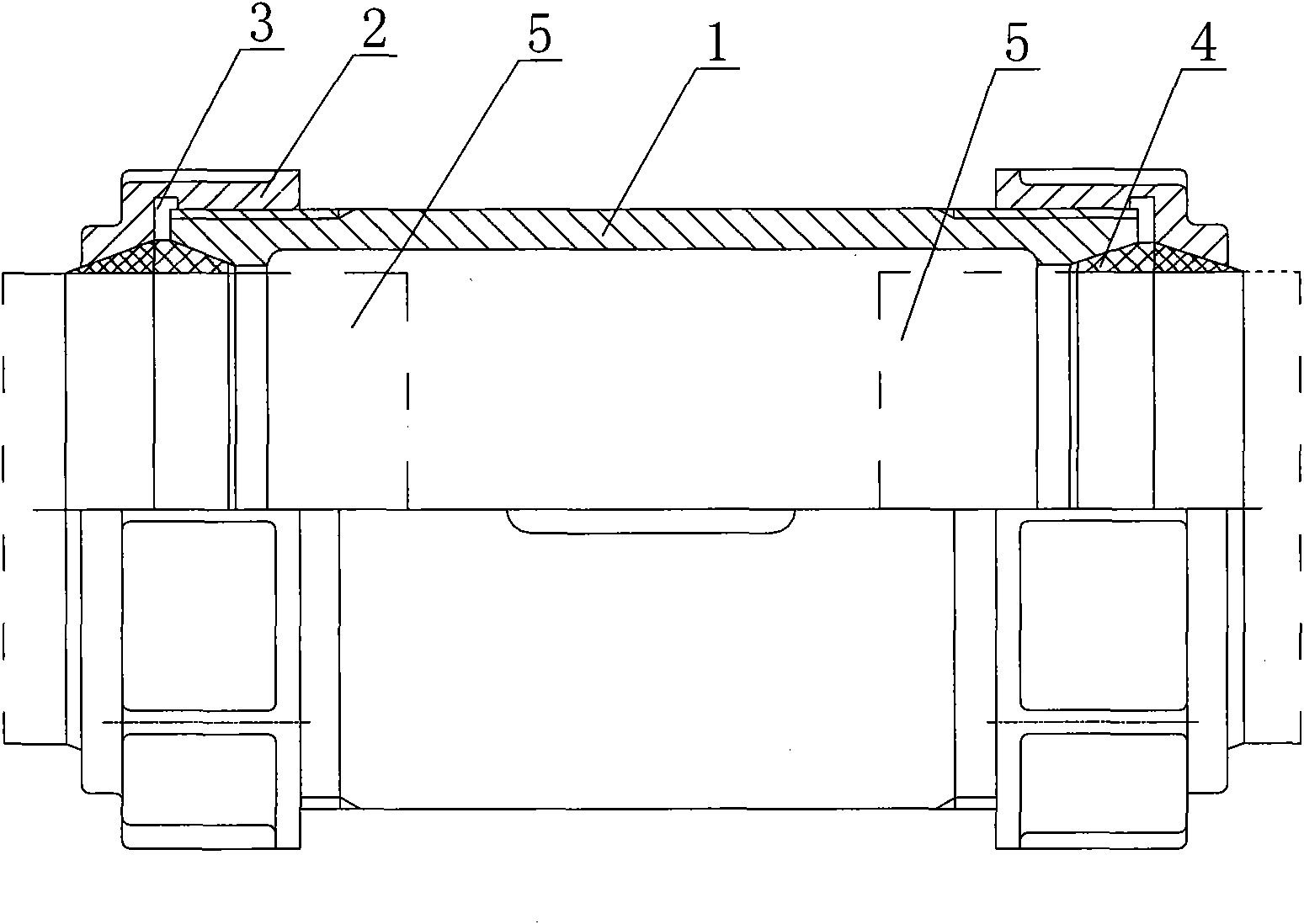

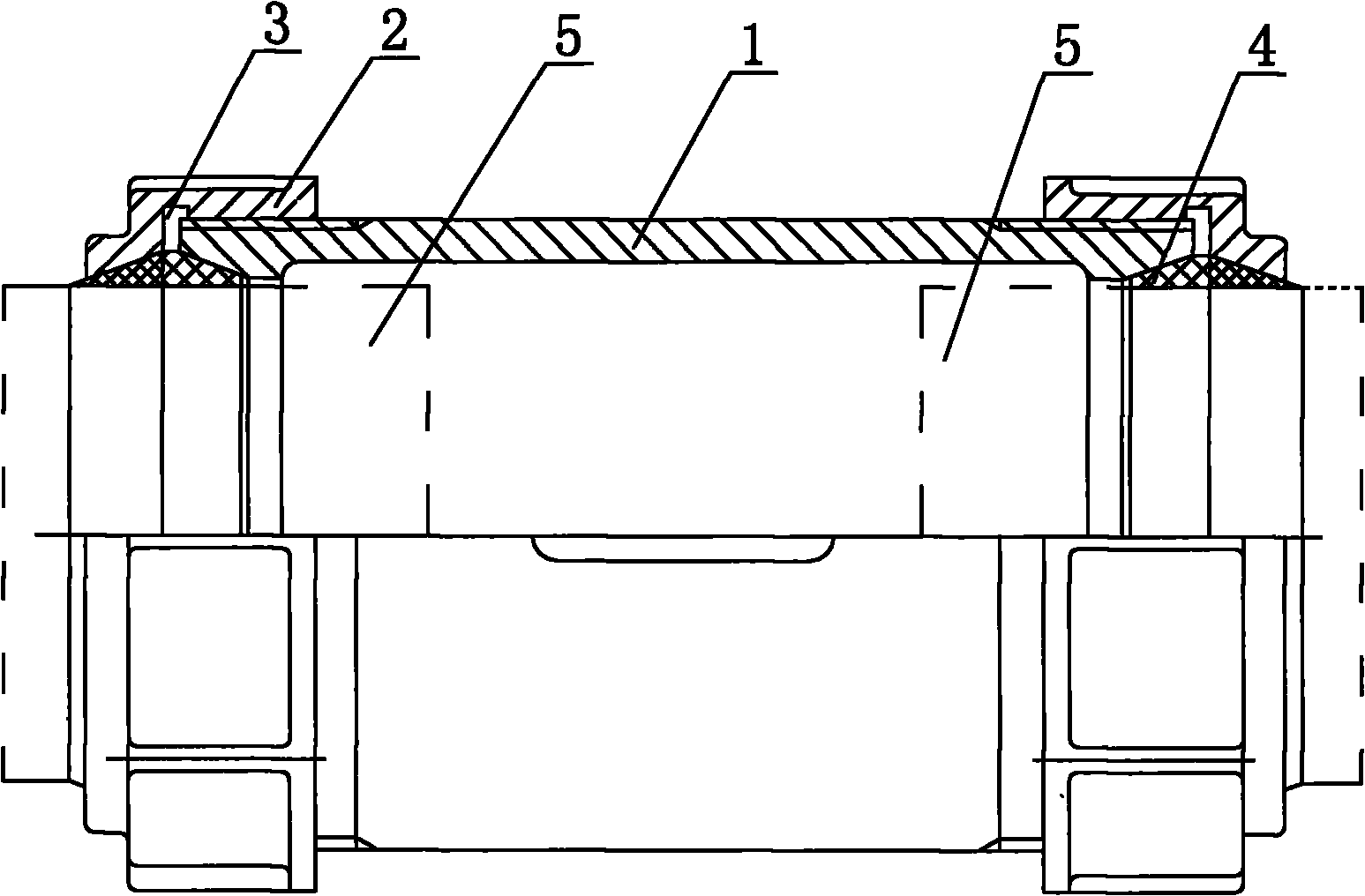

[0013] Please refer to figure 1 as shown, figure 1 It is a schematic diagram of the structure of the gas pipeline joint of the present invention. In this embodiment, a gas pipeline joint includes a body 1, a connecting pipe 5 communicating with the body 1 is installed on the body 1, and the body 1 The inner edges of both ends are inclined plane structures. A wedge-shaped sealing ring 4 is provided at the joint between the body 1 and the outer circle of the connecting pipe 5. The wedge-shaped sealing ring 4 is made of rubber material, and the wedge-shaped sealing ring 4 is placed by the body. 1. In the cavity formed by the inclined surface at the end, the fastening nut 2 and the connecting pipe 5, by tightening the fastening nut 2, the inclined surface of the fastening nut 2 presses the wedge-shaped sealing ring 4, so that the wedge-shaped sealing ring 4 produces elastic deformation and squeezes the body 1 bevel and fastening nut 2 bevel and the outer circle of the connecting ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap