Flaw inspection system for spring gasket and inspection method

A defect detection and spring washer technology, applied in the defect detection system of spring washer and its detection field, can solve the problems of high cost, high RPN value of failure analysis, single detection control measures or detection means, etc., and achieves convenient use and cost. The effect of revealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

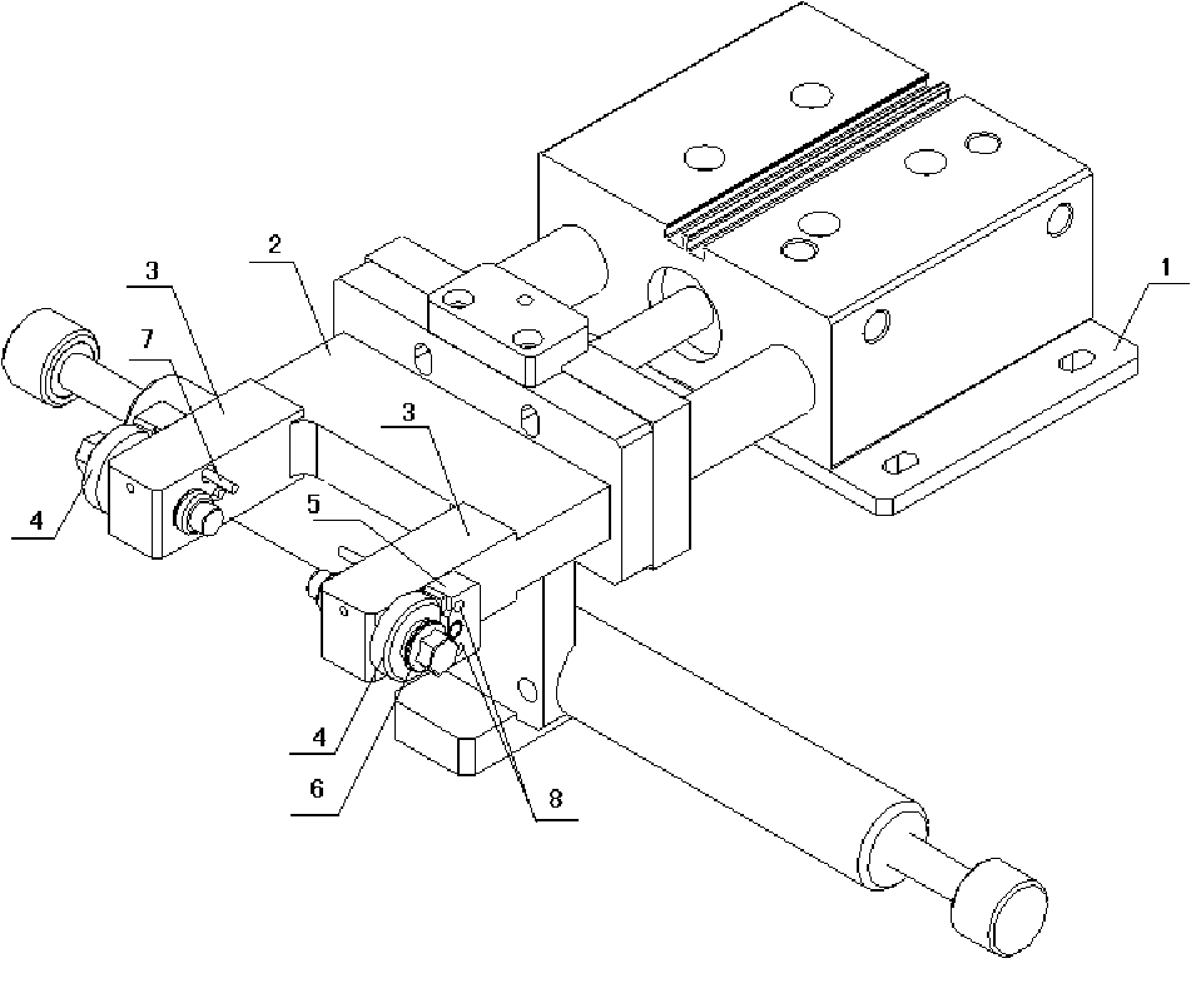

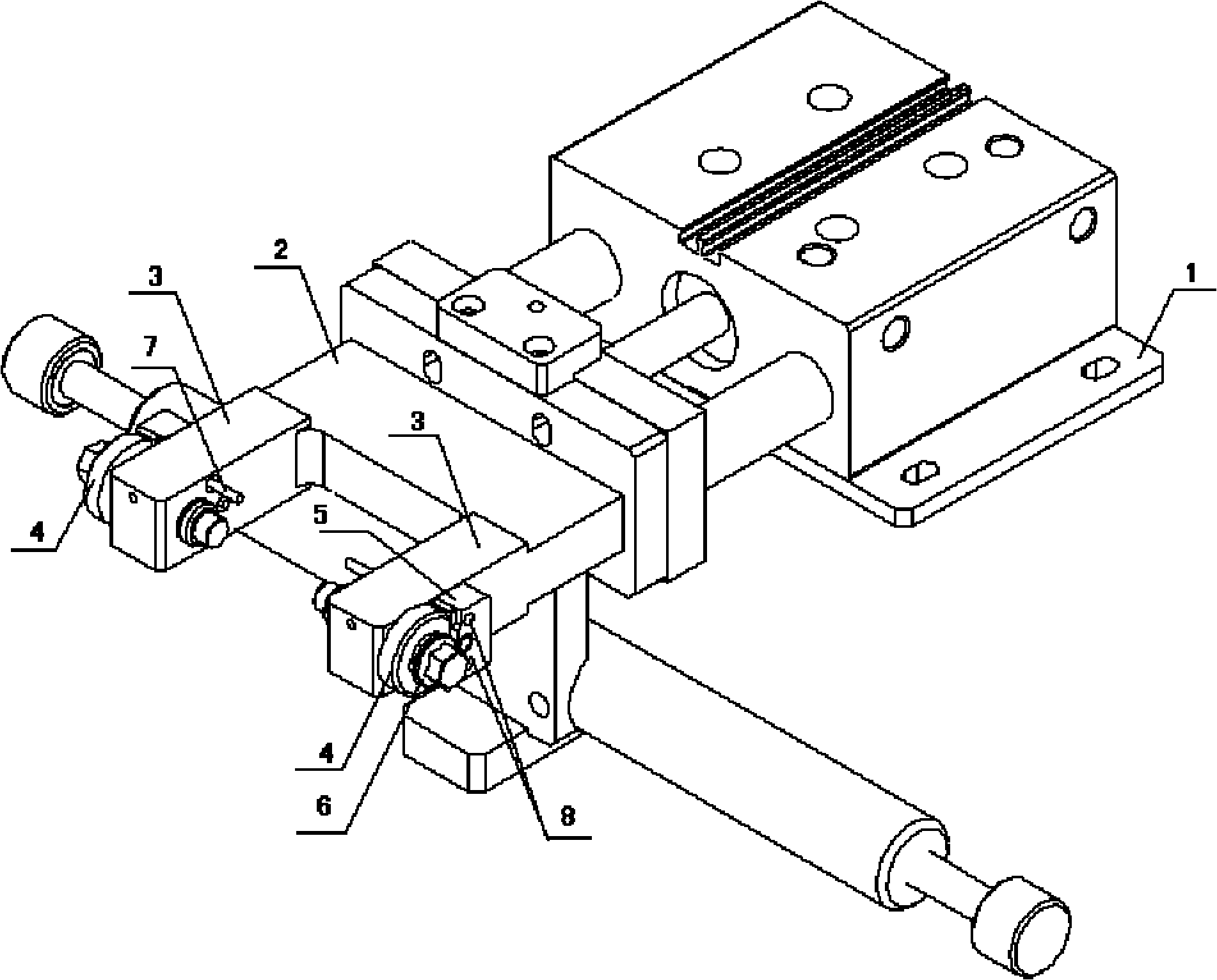

[0021] like figure 1 As shown, it is a structural schematic diagram of the defect detection system of the spring washer according to the present invention. The defect detection system includes a system support 2 connected to a fixed component 1, the system support 2 has two support walls 3 separated by a certain distance, and the entire system support 2 is axially symmetrical. The spring washers 6 are fixed on both ends of the bracket wall 3 through the installation parts 4 , and the defect detection system further includes proximity sensors 7 installed in pairs on corresponding positions of the two bracket walls 3 . The proximity sensor 7 can detect the distance between it and the opposite sensor.

[0022] Preferably, the defect detection system includes two pairs of proximity sensors 7 installed at corresponding positions on the two bracket walls 3 , and two proximity sensors 7 are installed on each bracket wall 3 .

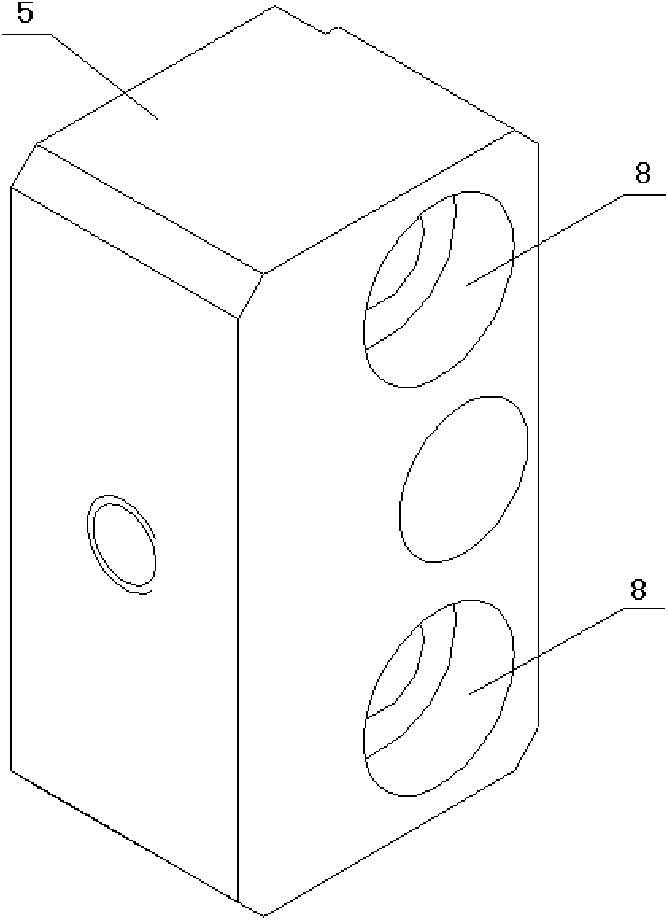

[0023] like figure 2 As shown, in the defect detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com