Lead crimping position corrector

A wire crimping and corrector technology, applied in the directions of circuit/collector parts, connections, electrical components, etc., can solve the problems of inconvenient construction on site, lack of correction tools, bending and deformation of hydraulic joints, etc., to achieve easy operation and high quality correction. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

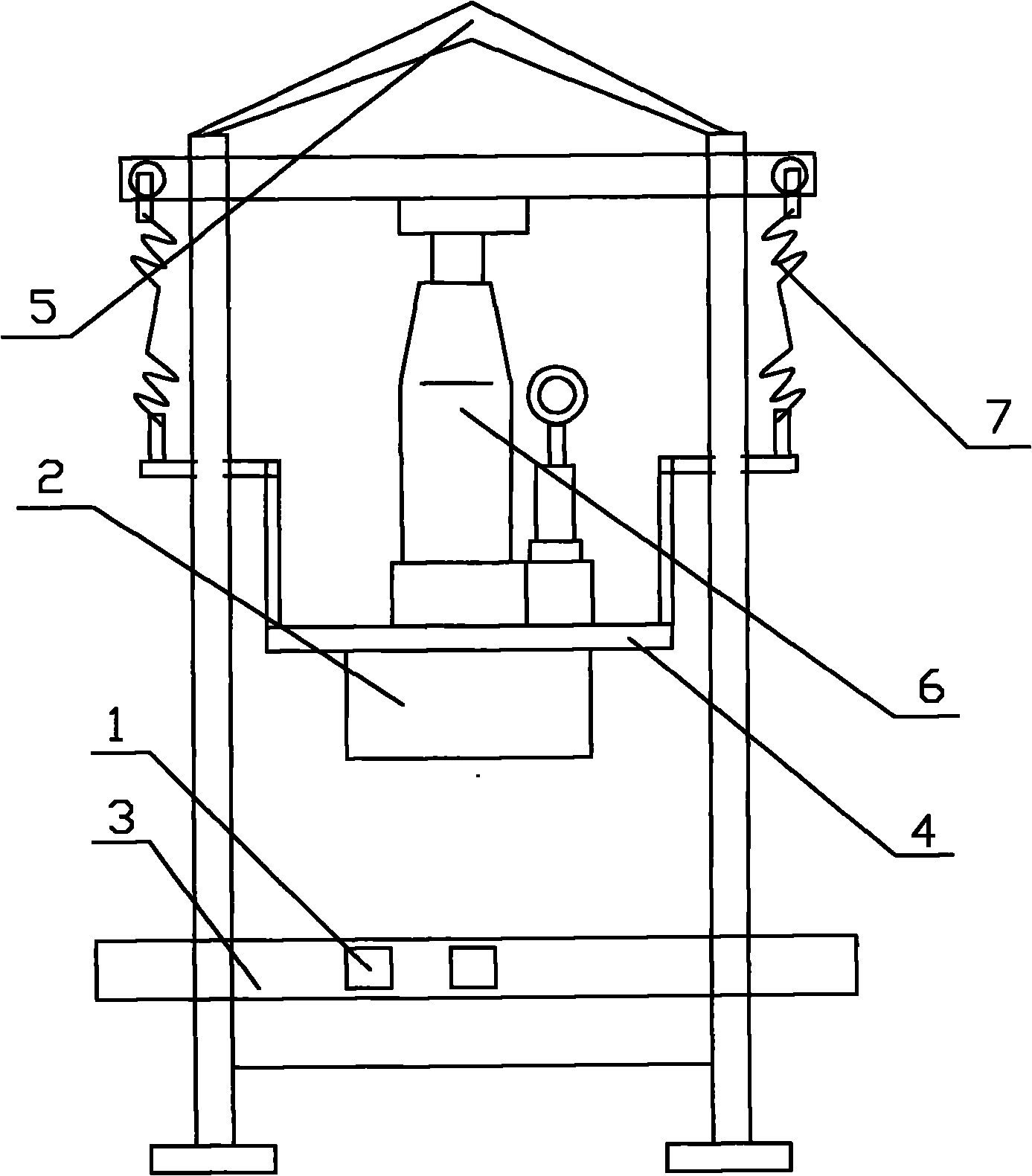

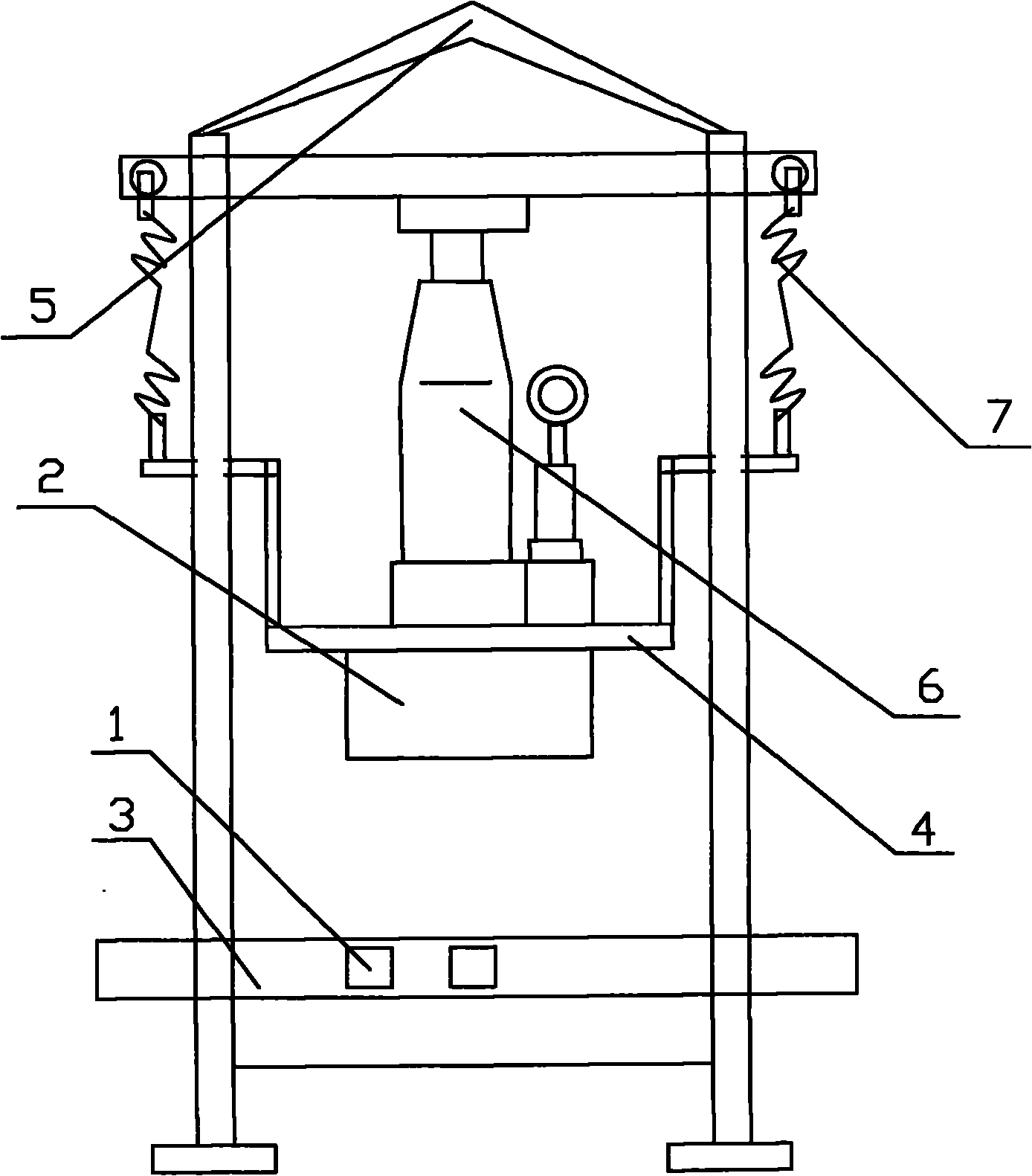

[0009] Such as figure 1 Shown: a wire crimping position corrector, including a main frame 5, a tension spring 7, an upper movable plate 4, a jack 6, an upper pressure groove 2, a lower groove 3, a movable spacer 1, the upper part of the main frame 5 An extension spring 7 is arranged on the beam, and the extension spring 7 is connected with the upper movable plate 4, the jack 6 is arranged on the upper movable plate 4, the upper pressure groove 2 is arranged on the lower movable plate 4, and the main frame The bottom of 5 is provided with lower groove 3, and described movable spacer 1 is the block that can move freely.

[0010] When in use, put the movable pad 1 into the lower groove 3, adjust the distance between the two movable pads 1 according to the type of wire or the degree of bending to make it in a suitable position, and then put it into the crimped and bent wire. Make the curved back of the wire face upward, and shake the jack 6 with the operating rod to move the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com