Tool for turning/turn broaching or external milling of work pieces

A workpiece turning and tool technology, applied in the direction of milling cutting inserts, milling cutters, broaches, etc., can solve the problem of inability to adjust the position of cutting inserts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

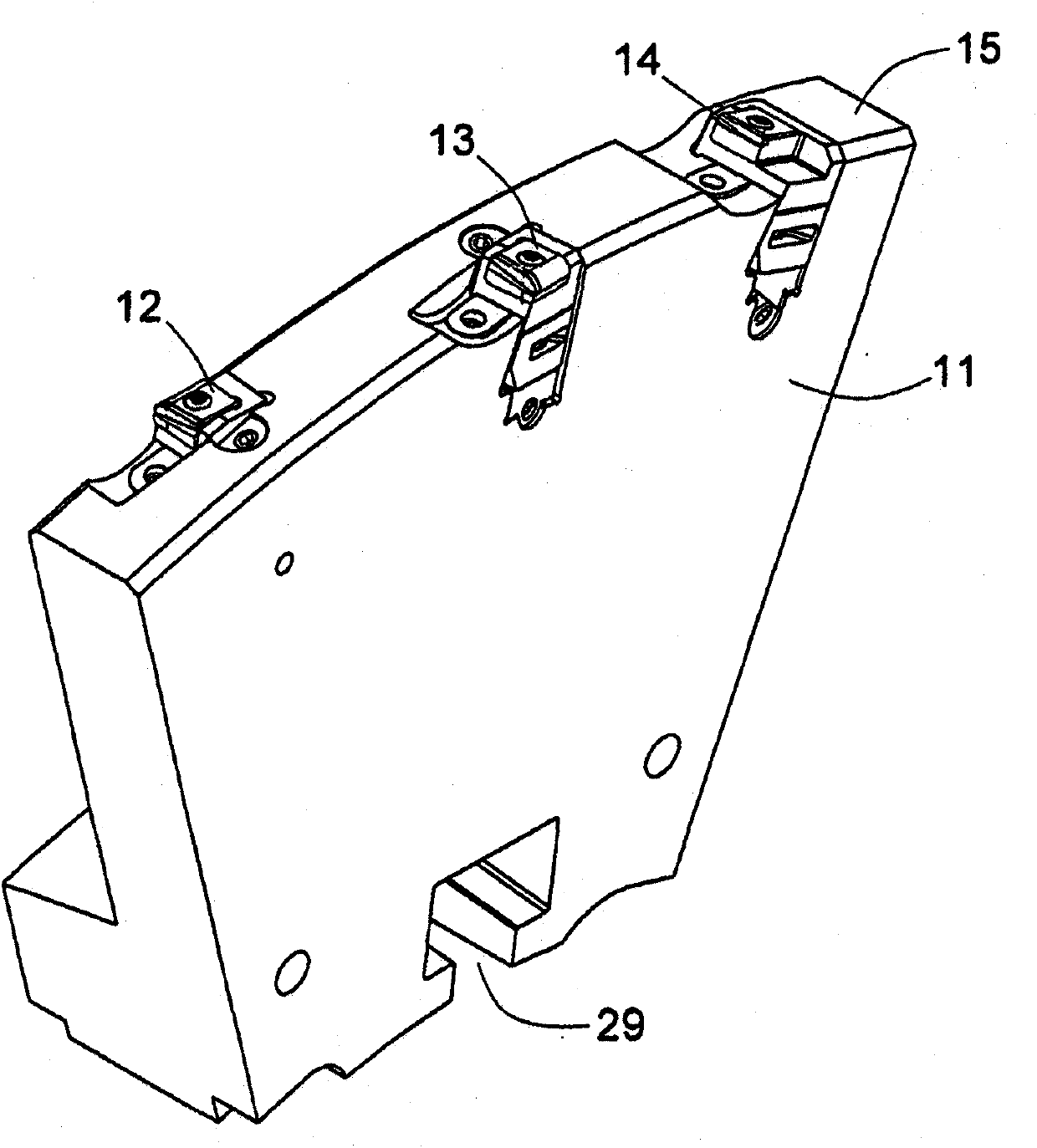

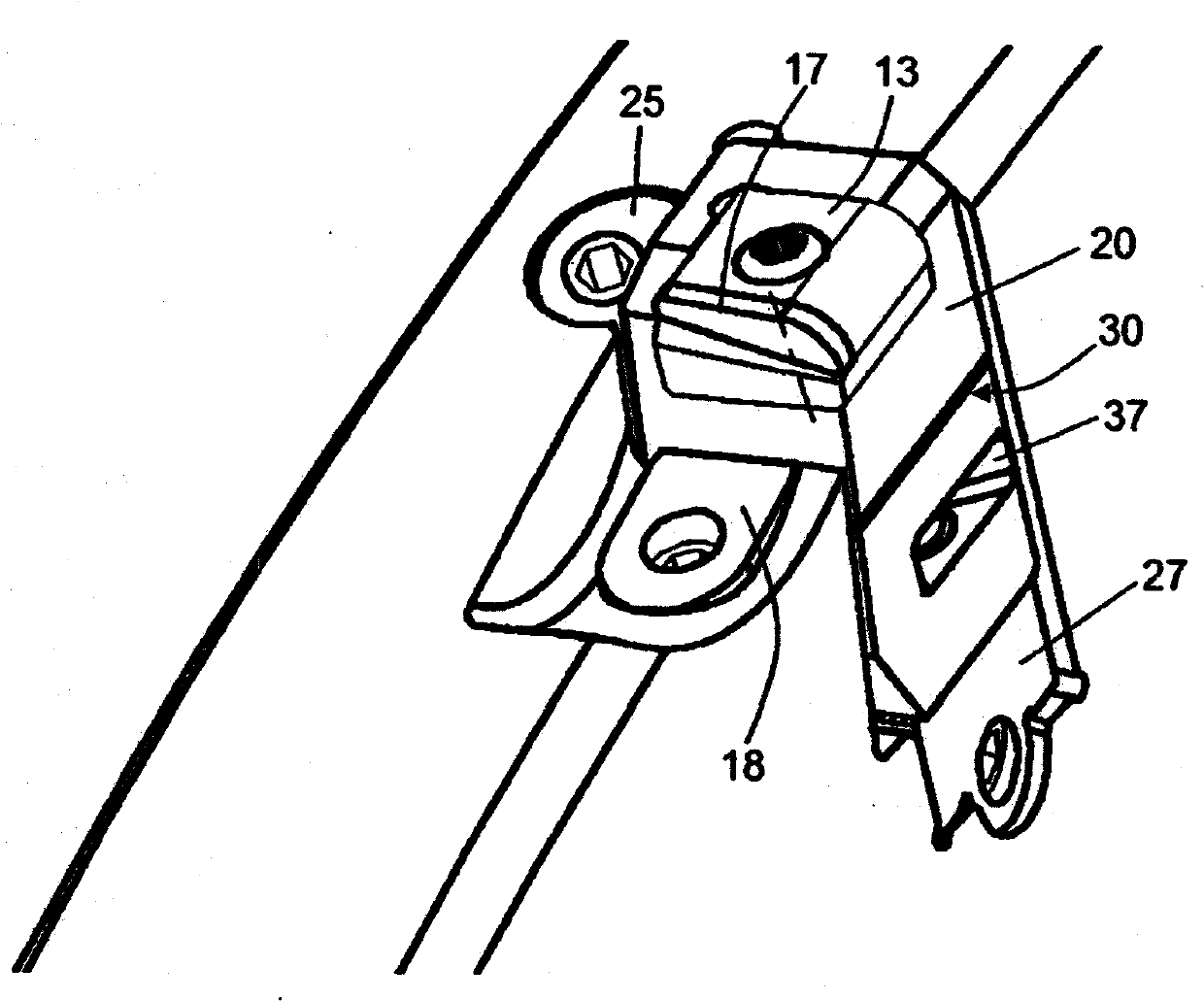

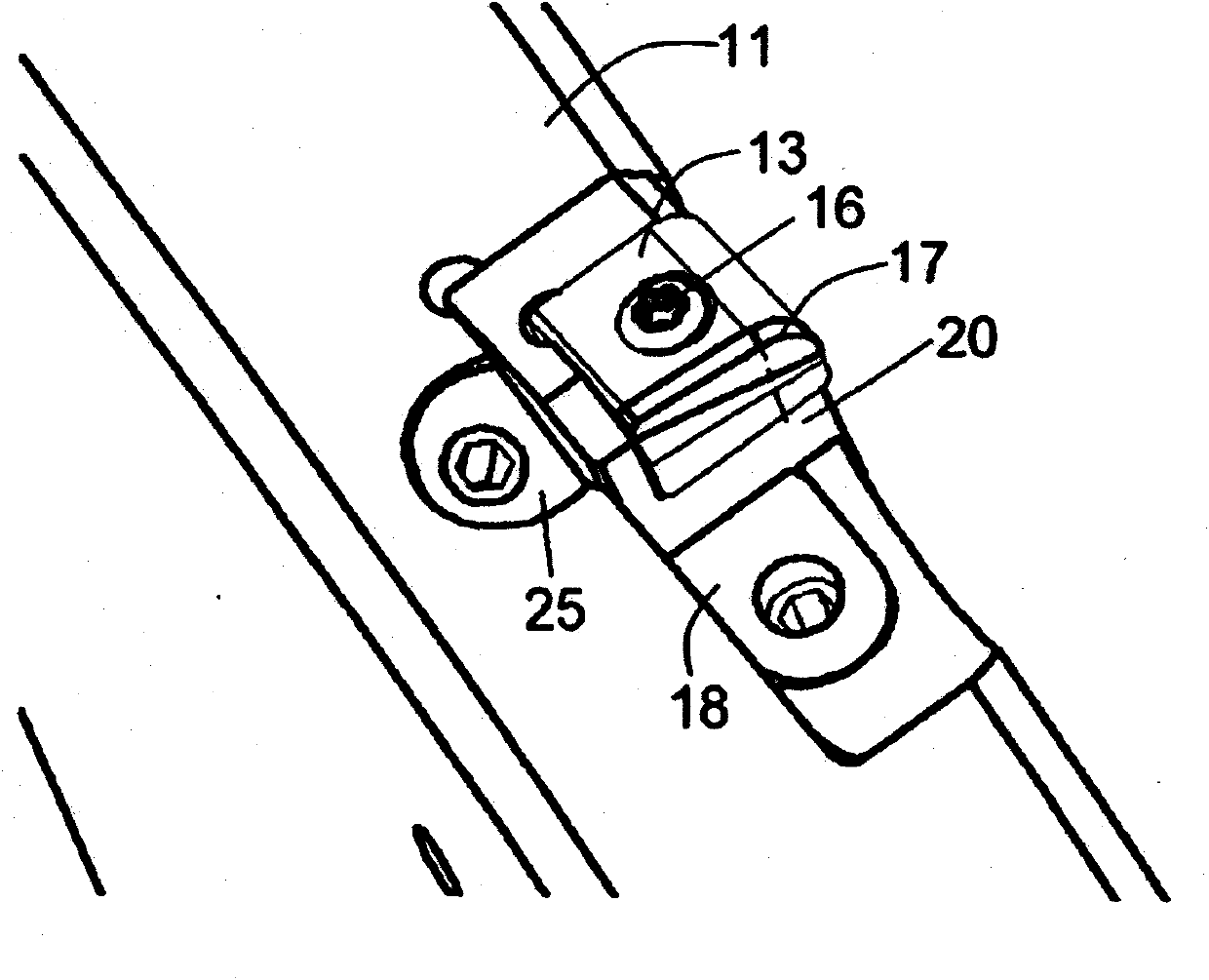

[0021] figure 1 Shown is a sector-shaped tool holder 11 having in its lower region an open slot-like recess 29 which is blind at one end and provides a stop point for the screw shank at its end . Clamping wedges are provided for axially clamping the sector 11 on a shaft (not shown). A plurality of segments 11 may be fastened side by side by suitable clamping members and thus may be fixed to form a complete ring around an existing shaft. Instead of segments 11 , it is also possible to fasten a one-piece ring body to a shaft. A plurality of cutting inserts, in this case clamped tangentially in place, are arranged peripherally in corresponding cassettes. exist figure 1 In , one cutting insert 12 is fastened laterally to the left, one cutting insert 13 is fastened laterally to the right and one cutting insert 14 is fastened centrally on the periphery 15 of the section. Such an embodiment is described in detail in German patent application 102007013153.6. Cutting inserts 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com