Use of a metal composite material in a vehicle structure

A composite material and multi-layer metal technology, which is applied in the direction of superstructure, metal layered products, thin material processing, etc., can solve the problems that cannot be optimized and realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

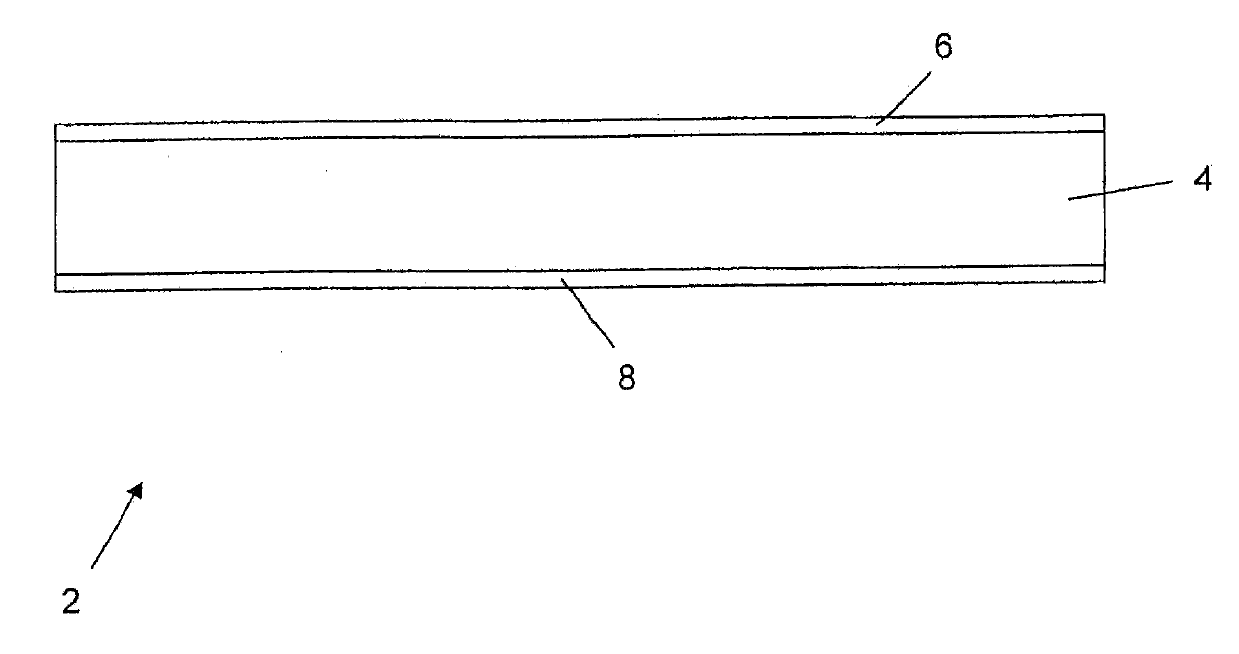

[0019] figure 1 A cross-sectional view of a typical three-layer composite 2 is shown. In this embodiment, the composite material comprises a middle layer 4 made of soft, easily formable alloy steel and two outer layers 6, 8 made of high-strength or very high-strength Made of high strength alloy steel. The outer layers 6, 8 on both sides can be made of the same alloy steel. However, it is also possible for the outer layers 6 , 8 to consist of different steel alloys, for example in the case of an application of the composite material 2 in which the different sides are loaded to different degrees. In this embodiment, the thicknesses of the outer layers 6, 8 on both sides are substantially equal. Of course, it is also possible to make the thicknesses of the three layers 4, 6, 8 different from each other. The composite material 2 can also have a metallic and / or organic coating (not shown) on one side or on both sides. For example, an aluminum-based coating or lacquer coating i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com