Retroreflector label sheet and article to which retroreflector label sheet is bonded

A technology for label sheets and articles, applied in the field of retroreflector label sheets, can solve the problems of no longer use, weakened adhesive force of the adhesive layer, damage to the glass bead layer, etc., and achieve the effect of preventing counterfeiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

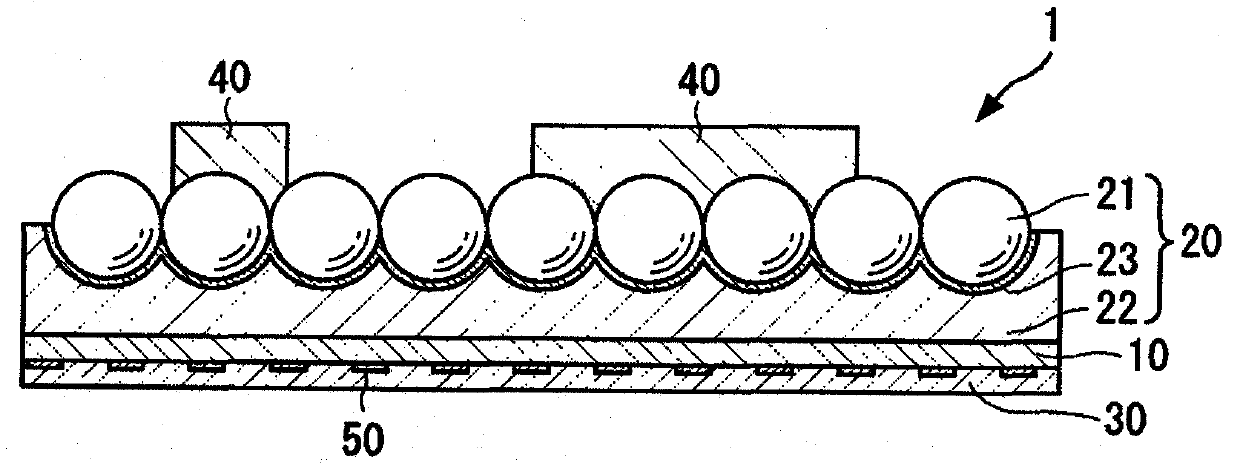

[0044] Such as figure 1 As shown, the retroreflective label sheet 1 of the first embodiment includes: a base material layer 10; The detection light is retroreflected in the same direction; the adhesive layer 30 is laminated on the other side of the base layer 10 and is bonded to the article; the easily destructible layer 40 is arranged on the surface of the retroreflective layer 20 at least a part; and background information 50 composed of patterns, characters, etc. formed by printing on the surface of the substrate layer 10 on the side of the adhesive layer 30 . In this embodiment, the background information 50 is configured so that it can be seen from the front side of the retroreflective label sheet 1 . That is, the retroreflective layer 20, the fragile layer 40, and the base layer 10 are transparent. In addition, the background information 50 may be provided on the surface of the base material layer 10 on the retroreflective layer 20 side. To make the retroreflective la...

no. 2 Embodiment approach

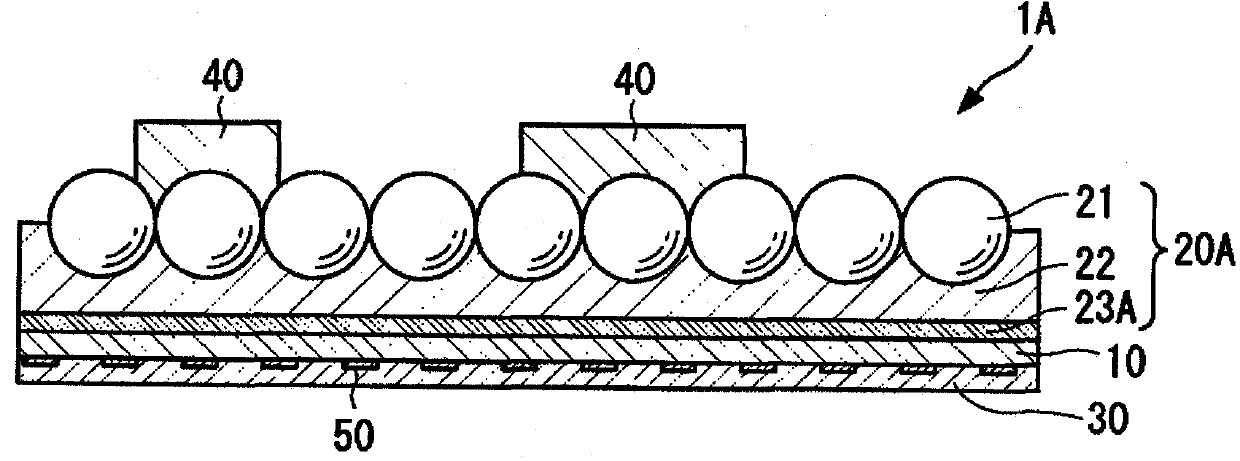

[0071] Such as figure 2 As shown, the retroreflective label sheet 1A of the second embodiment includes: a base layer 10; a retroreflective layer 20A, which is laminated on one surface of the base layer 10, is transparent, and when the detection light is incident from a predetermined direction The detection light can be retroreflected in the same direction; the adhesive layer 30 is laminated on the other side of the base material layer 10 and bonded to the article; a part on the surface; and background information 50 formed of a pattern or characters on the surface of the base material layer 10 on the side of the adhesive layer 30 .

[0072] The retroreflective layer 20 includes a photorefractor layer 21 covered with glass beads, a holding layer 22 for maintaining the photorefractor layer 21 in a state where its surface is exposed, and a layer laminated on the surface of the photorefractor layer 21. The reflective layer 23A is laminated on the surface on the side opposite to ...

no. 3 Embodiment approach

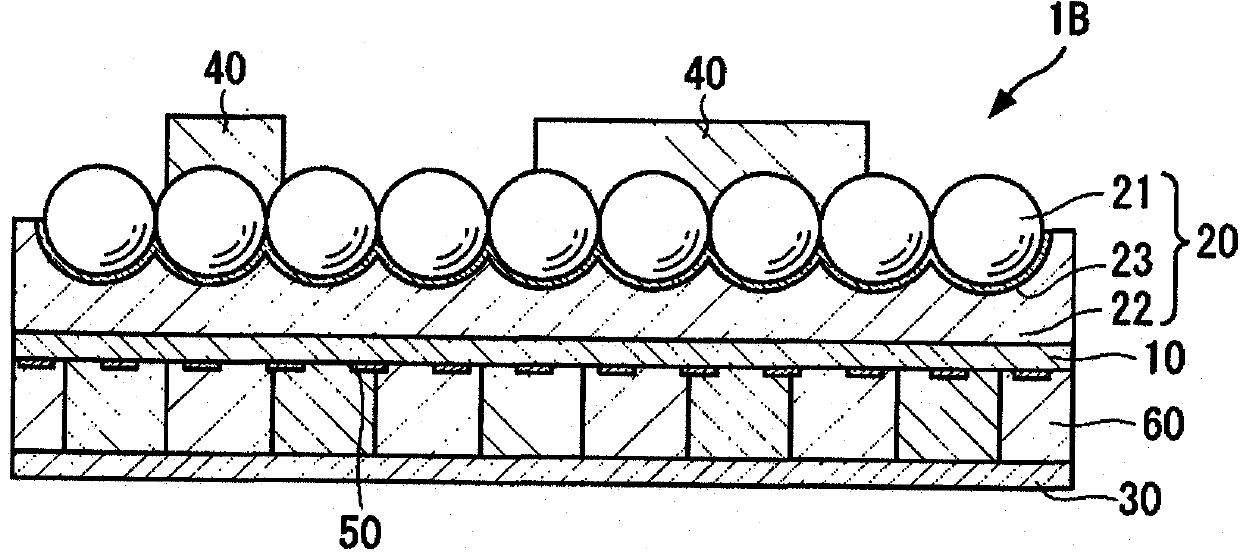

[0076] Such as image 3 As shown, the retroreflective label sheet 1B of the third embodiment includes: a base layer 10; a retroreflective layer 20, which is laminated on one surface of the base layer 10, is transparent, and when the detection light is incident from a predetermined direction The detection light can be retroreflected in the same direction; the adhesive layer 30 is laminated on the other side of the base layer 10 and is bonded to the article; the peeling damage layer 60 is formed on the base layer 10 and between the adhesive layers 30; the fragile layer 40, which is provided on a part of the surface of the retroreflective layer 20; form. The retroreflective layer 20 has the same structure as that of the first embodiment, and includes a photorefractor layer 21 covered with glass beads, a holding layer 22 that keeps the photorefractor layer 21 in a state where its surface is exposed, and The reflective layer 23 is laminated on the surface of the light refractor l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com