Connecting method of built-in pipeline of multi-filter-core back-flushing water purifier

A flushing water purifier and connection method technology, which is applied in the field of built-in pipeline connection of multi-filter backflushing water purifiers, can solve problems affecting the popularization of water purifiers, and achieve the effects of convenient maintenance, high-grade products, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

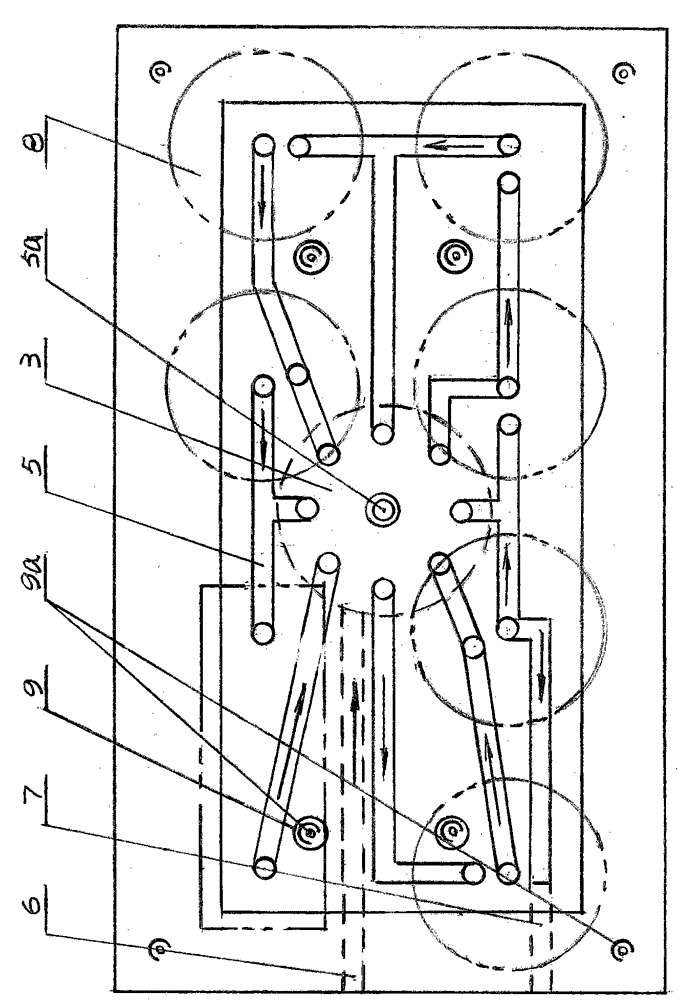

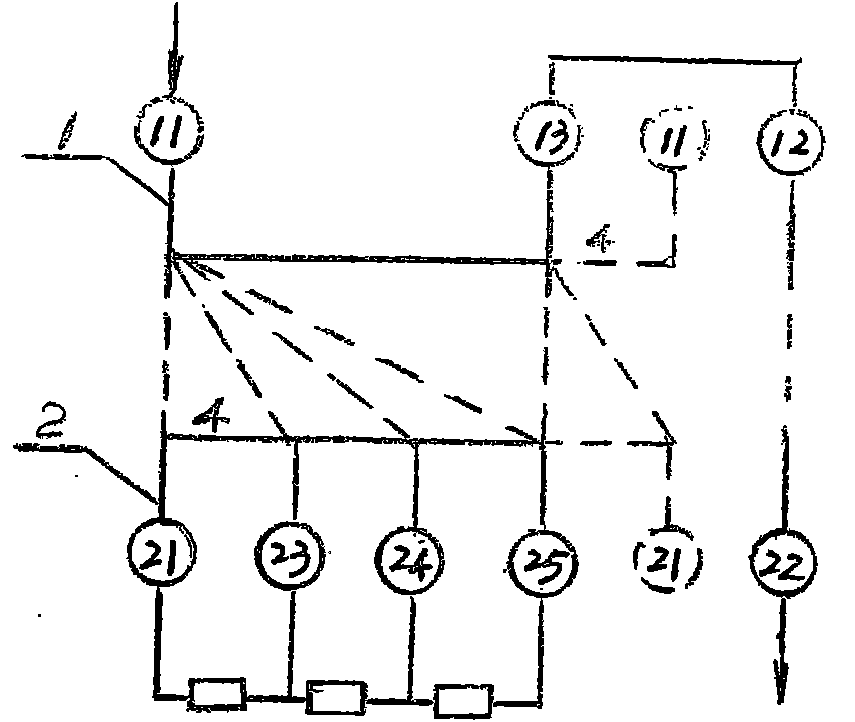

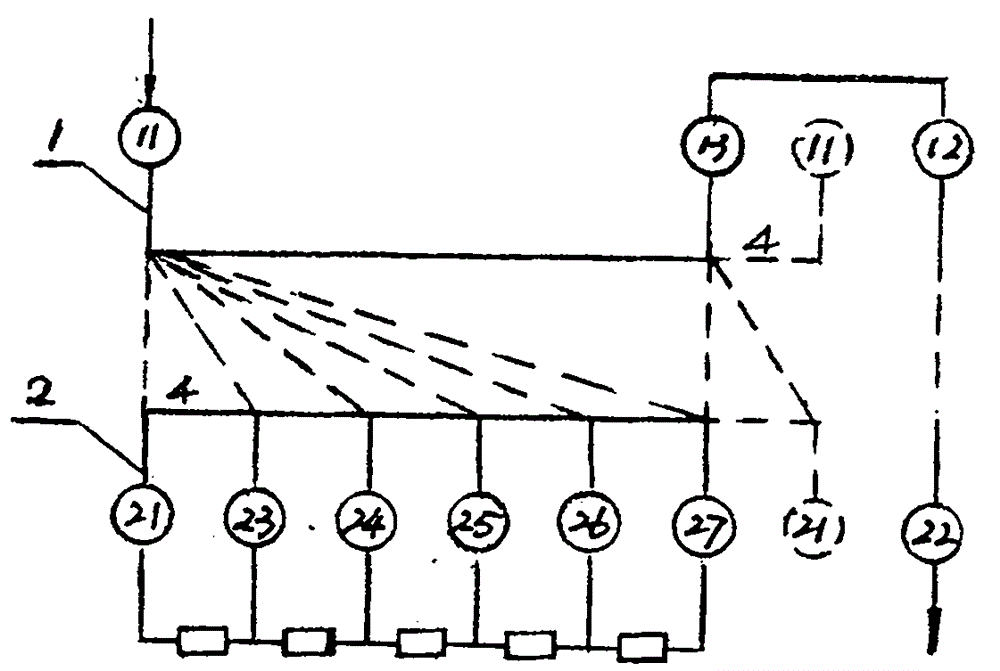

[0044] figure 1 , Figure 4 The best embodiment of the present invention is shown. Adopt different disc connection, eight nozzles and other switching angle waterway switcher combined with seven two nozzle filter elements, closed loop switching, open slot connection mode, its controlled disc 2 is evenly distributed with eight switching nozzles, and the corresponding equal switching angle unit 4 is 45° . In order to facilitate the replacement of the filter element, the closed filter element 8 adopts an inverted, inner and outer nozzle structure, and the outer nozzle is the water inlet; the central inner nozzle is the water outlet. The frame adopts a frame-type double-layer inverted combination structure: the upper layer is the filter element replacement area for easy loading and unloading of the filter element; the lower layer is the recoil switching area for the switching operation of the recoil channel. The inner cavity 3 is sealed with a sealing cover with a shaft hole and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com