Parting liquid spraying device

A technology of spraying device and nozzle, which is applied in the direction of casting molding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unsafe operation, slow speed, and affecting productivity, etc., and achieve the effect of solving danger, improving productivity, and good trial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

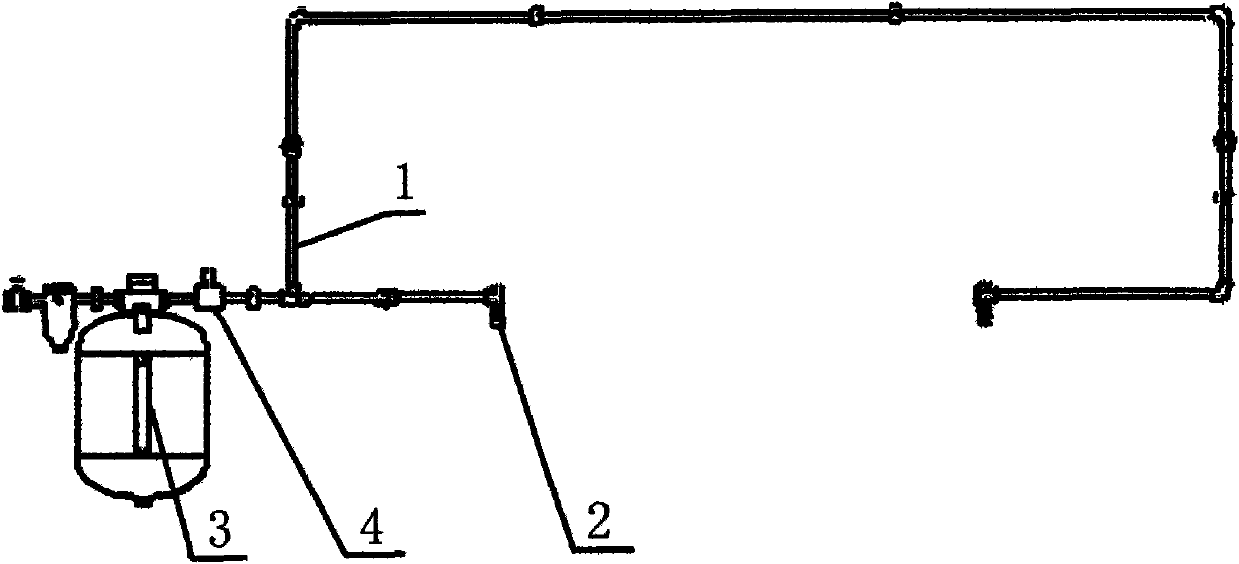

[0011] The parting liquid spraying device as shown in the figure includes a set of interconnected pipes 1 with two nozzles 2 on both sides of the pipe. The position and distance of the two nozzles can be adapted to the needs of installing on both sides of the upper part of the mold. , The pipeline is used to transport the ventilation source and the parting liquid, and the ventilation and shut-off of the entire pipeline are controlled by the gas valve. When ventilating, the airflow drives the parting liquid to spray onto the mold in a mist. When the air is cut off, the parting liquid will not be sprayed.

[0012] An oil mist device 3 and a throttle valve 4 for controlling the gas flow and pressure are also provided on the pipeline for conveying high-pressure gas, so that the high-pressure gas entering the parting liquid pipeline can be controlled, and it is also an indirect adjustment form of the spray volume .

[0013] The parting liquid spraying device provided by the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com