Automatic instantaneous inoculation device for casting of casting machine

A technology of inoculation device and pouring machine, which is applied in the field of mechanical casting, can solve the problems of unstable casting quality, small capacity of inoculant tank, and easy safety problems, and achieve the effects of avoiding personal injury, improving production efficiency, and saving labor and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

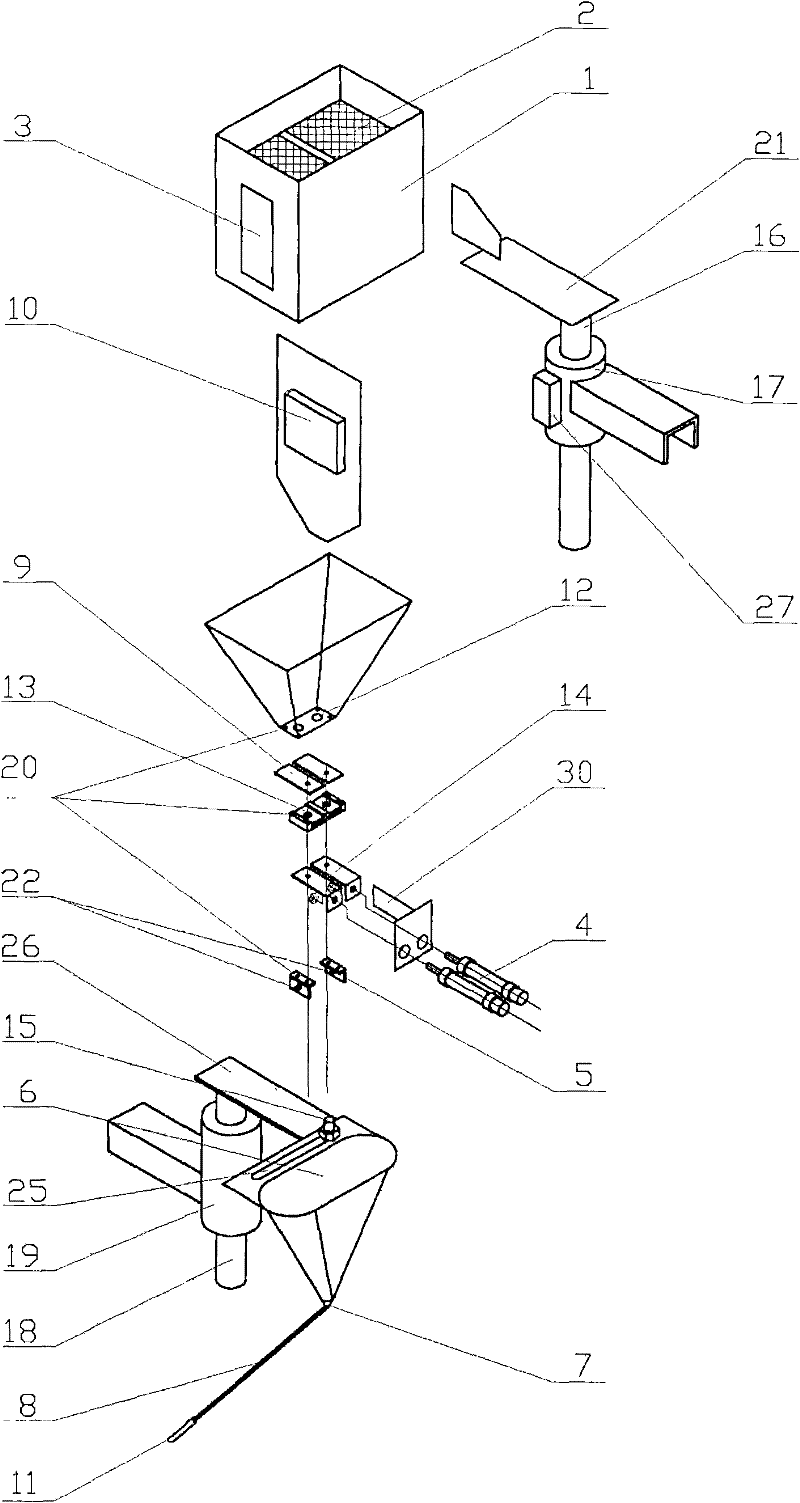

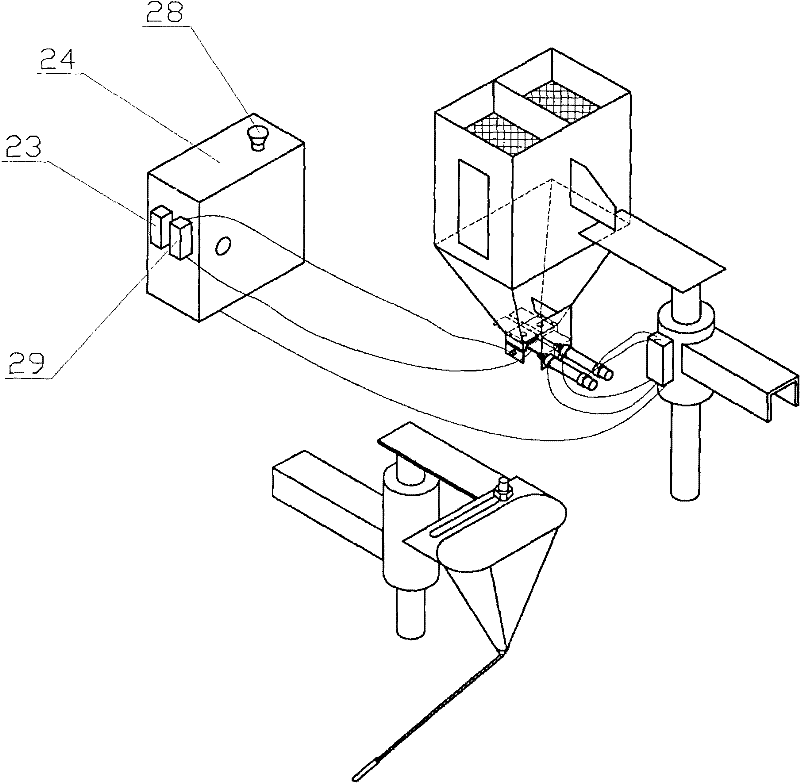

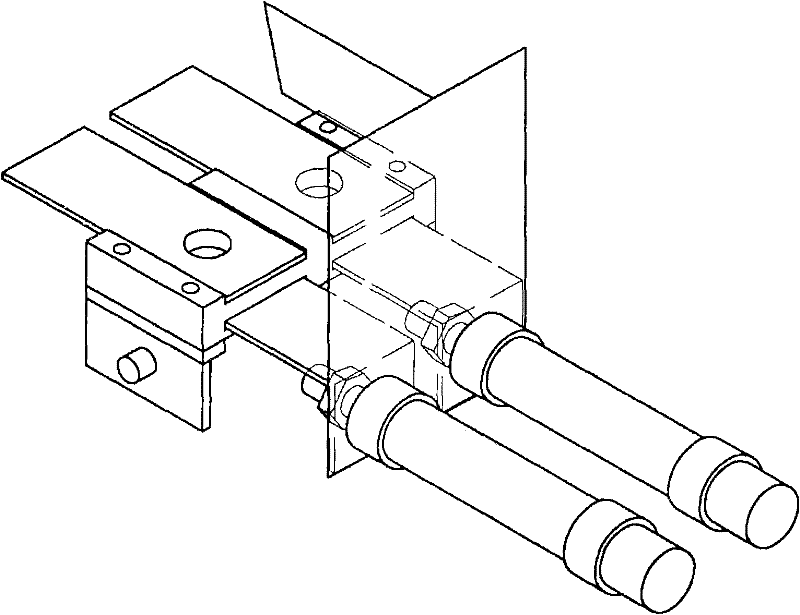

[0023] refer to figure 1 —— Figure 4 As shown, the present invention comprises: tank body 1, tank body 1 adopts 1mm steel plate welding to make, and the upper part of tank body 1 is a square body and the lower part tapers into an inverted trapezoidal shape, and is used for accommodating and storing the inoculant. The side of tank body 1 is provided with several observation holes, and present embodiment: is provided with 1 observation hole 3, and the size of observation hole 3 is: 100mm * 30mm, and a transparent plexiglass is inlaid on the observation hole, and plexiglass adopts 3mm thick organic glass. Made of glass, used as an observation window for inoculant inventory.

[0024] A steel filtering steel mesh 2 is installed on the tank body 1, and the steel filtering steel mesh 2 is fixed on the upper end of the tank body 1 by connecting bars and screws. The density of the filter screen 2 is 30 mesh. When adding the inoculant, it is used to prevent oversized inoculant or im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com