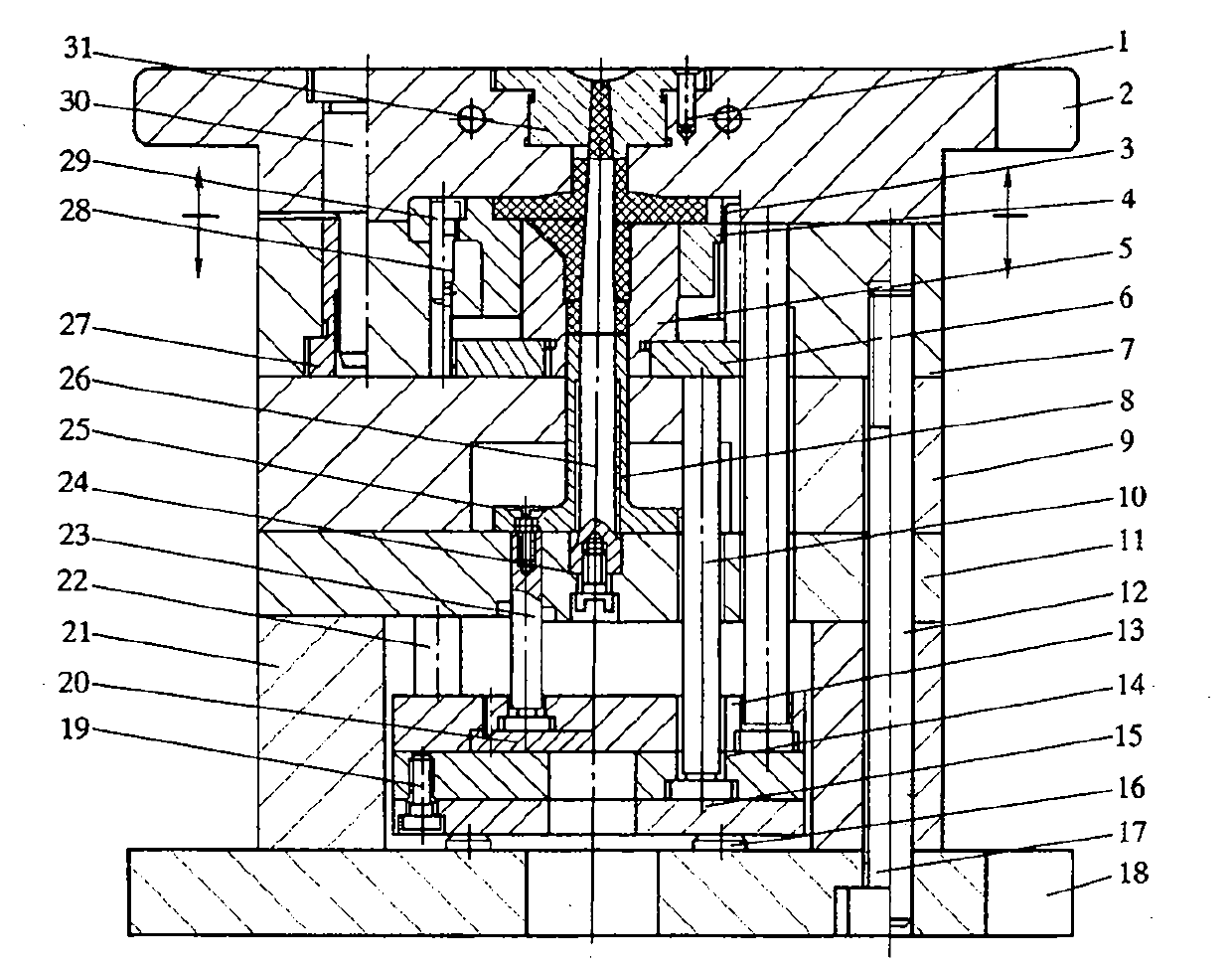

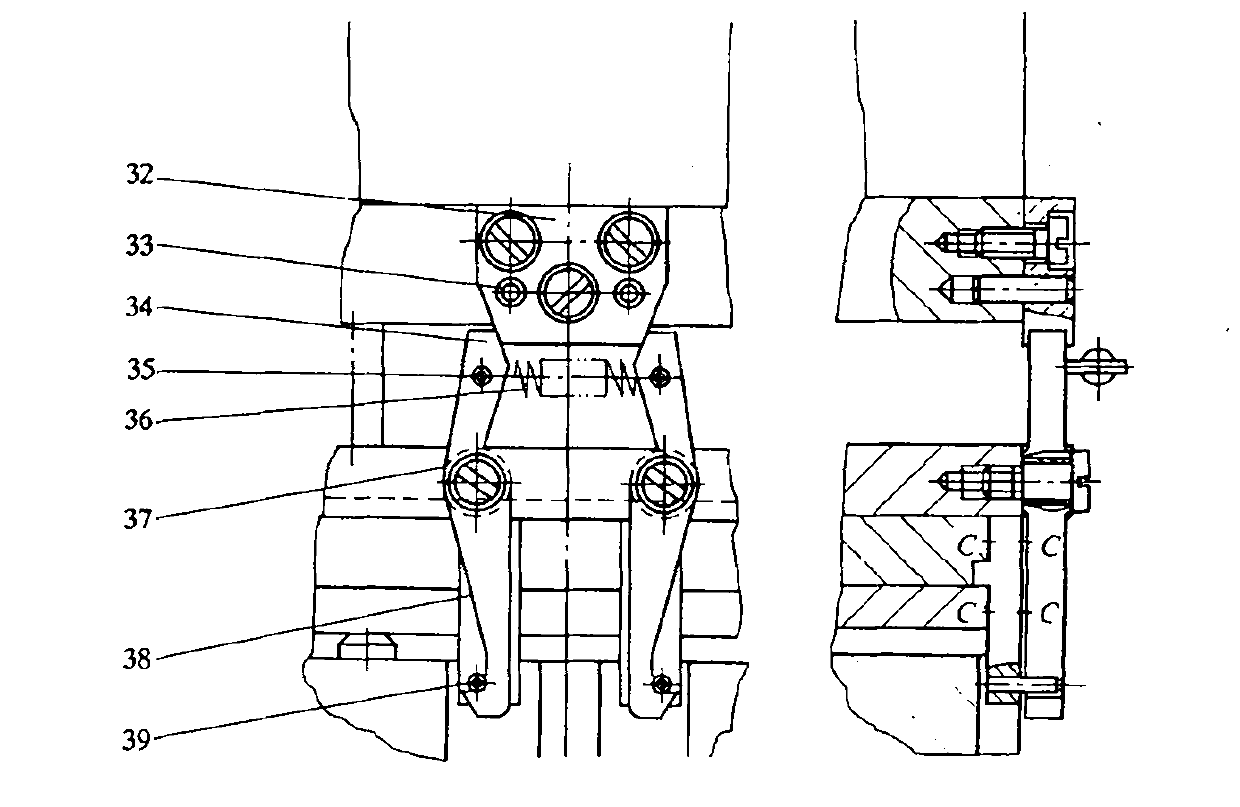

Draw hook-type two-stage ejection die mechanism

A two-stage ejection, mold mechanism technology, applied in the field of metal die-casting mold and plastic injection mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Shown in the figure is the hook-type secondary ejection mold mechanism, its working principle: the primary push plate 15 and the secondary push plate 13 of the mold ejection mechanism are connected into one body through two pairs of pull hooks 34, when the two-stage push plate starts to push out Synchronous action, the push rod 10 of the first-stage push plate pushes the fixed plate 6 and the large-area push block 5, the product is separated from the die 4 and loosened from the core 26, and the first-stage push is completed. When drag hook 34 hits wedge 32 and rotates to make the first and second-level push pedals unhook, the first-level push pedal stops moving, and the second-level push pedal continues to move forward, and push rod 23 drives push tube 8 to push the product out of the mold completely. Reset rod 3 is arranged on the secondary push-out mechanism, and the primary push plate is reset together when it resets. Above-mentioned action repeats movement back and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com