Method for quickly and accurately positioning die in injection molding process

A precise positioning and mold technology, which can be used in the injection molding process to quickly and accurately locate the mold, solve the problems of unusable track error, difficult to achieve mold positioning, and inability to use well, and achieve shortened time, shortened time, The effect of reducing vibration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

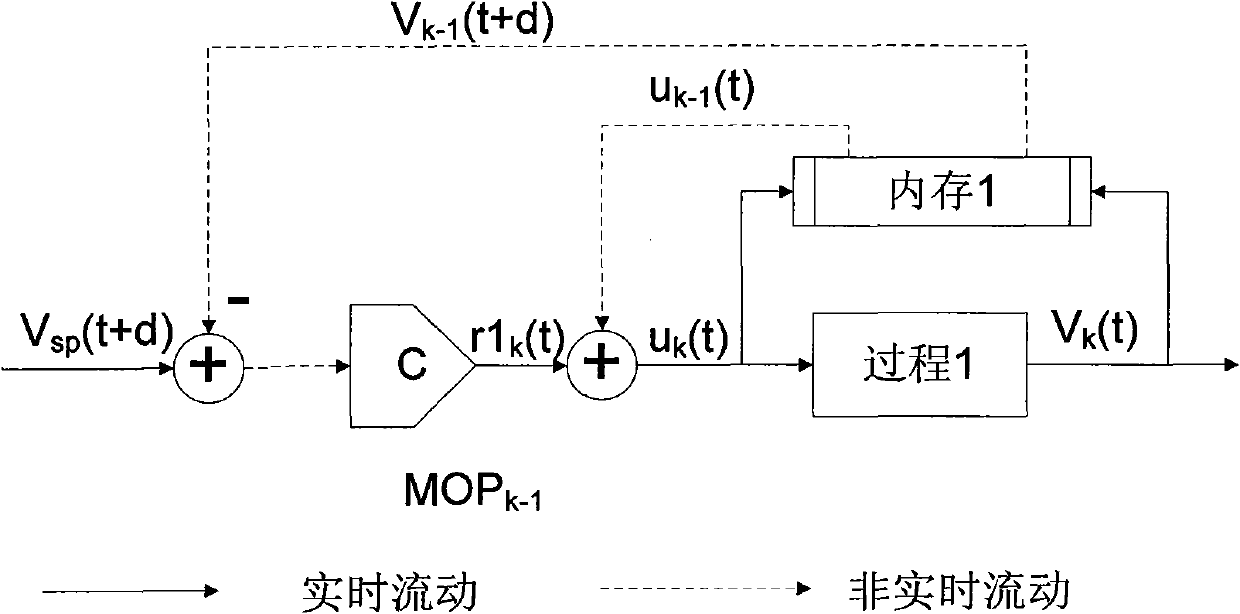

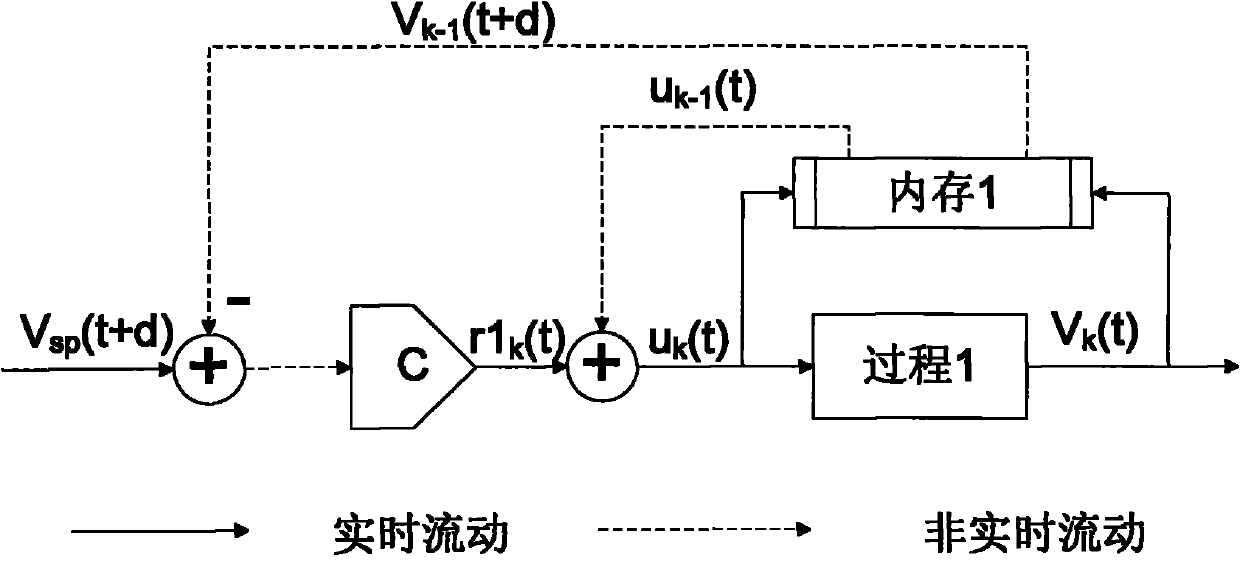

[0050] Such as figure 1 As shown, in the process of the Kth cycle, the reference speed V of the mold at the moment (t+d) k (t+d) and the speed V at the moment (t+d) in the last cycle K-1 stored in memory 1 k-1 (t+d) Through the calculator, compare and get V k (t+d)-V k-1 (t+d), V k (t+d)-V k-1 (t+d) Through the learning of the controller C, the input signal Kp*V is obtained k (t+d)-V k-1( t+d), where Kp is the learning rate of the controller, and the input signal is compared with the speed V of the mold at time t in the previous cycle stored in the memory 1 k-1 (t) Through addition, the input signal is obtained, that is, the speed u of the valve at the time of the K-th cycle t k (t), on the one hand, this input signal will be stored in the memory 1 for the next cycle of learning, on the other hand, it will control the process 1 to obtain the output signal V k (t), that is, the speed of the mold at the time t of the K cycle. Repeat learning in this way until the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com