Vertical transportation hanger

A vertical transportation and hanger technology, which is applied in the field of hangers, can solve the problems of unsafe open buckets, messy construction sites, and restrictions on the construction period, and achieve the effect of simple structure, easy promotion, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

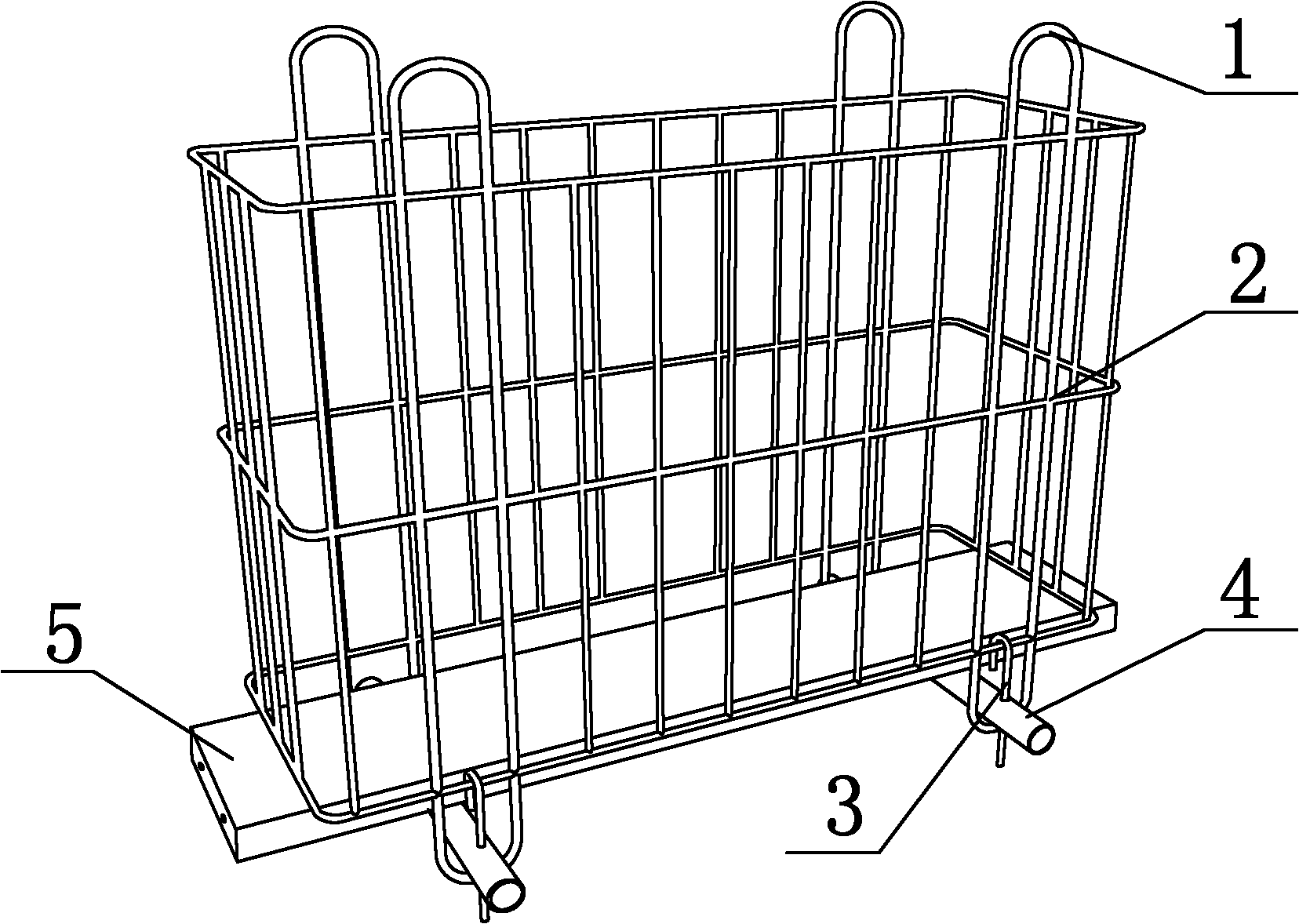

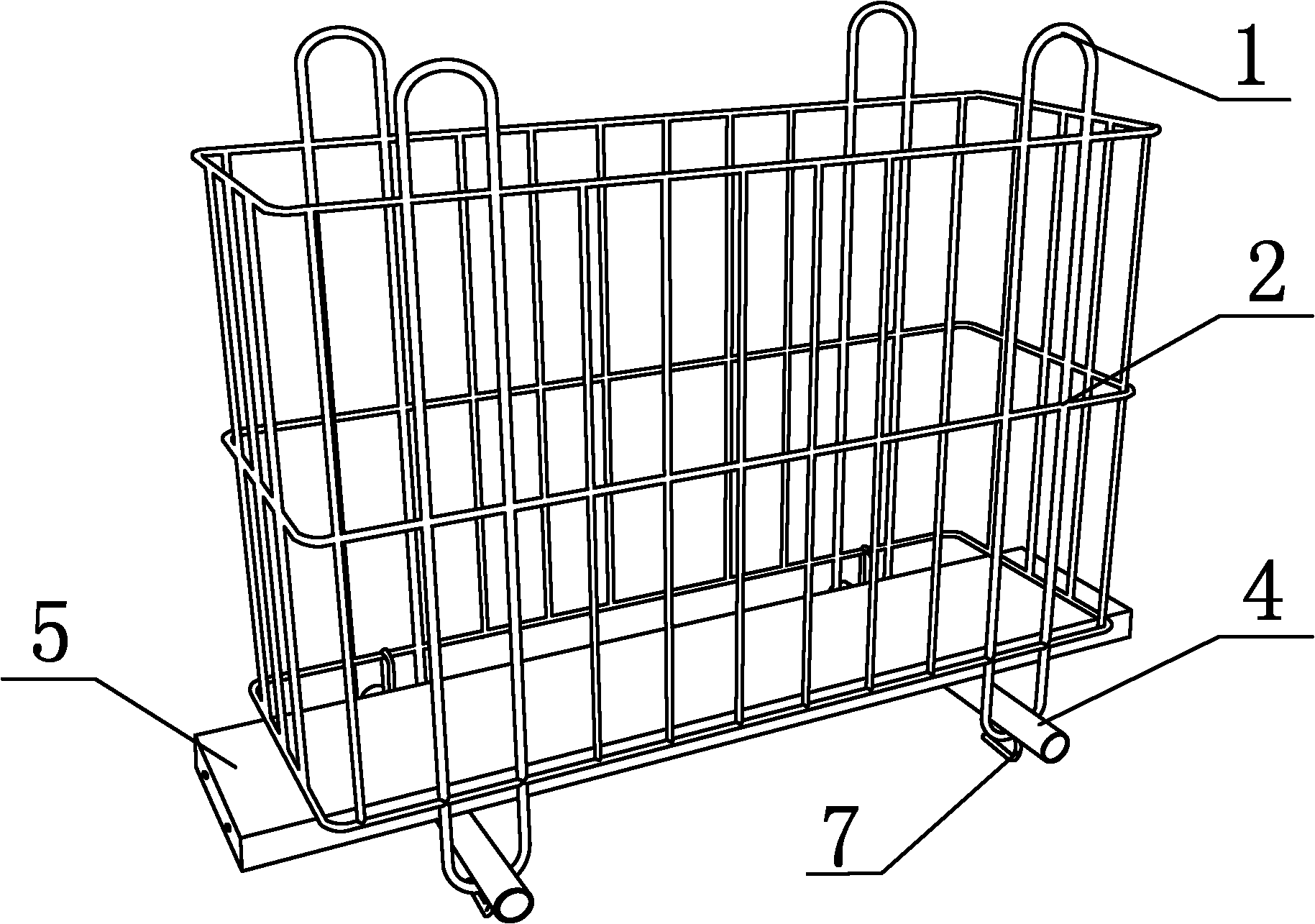

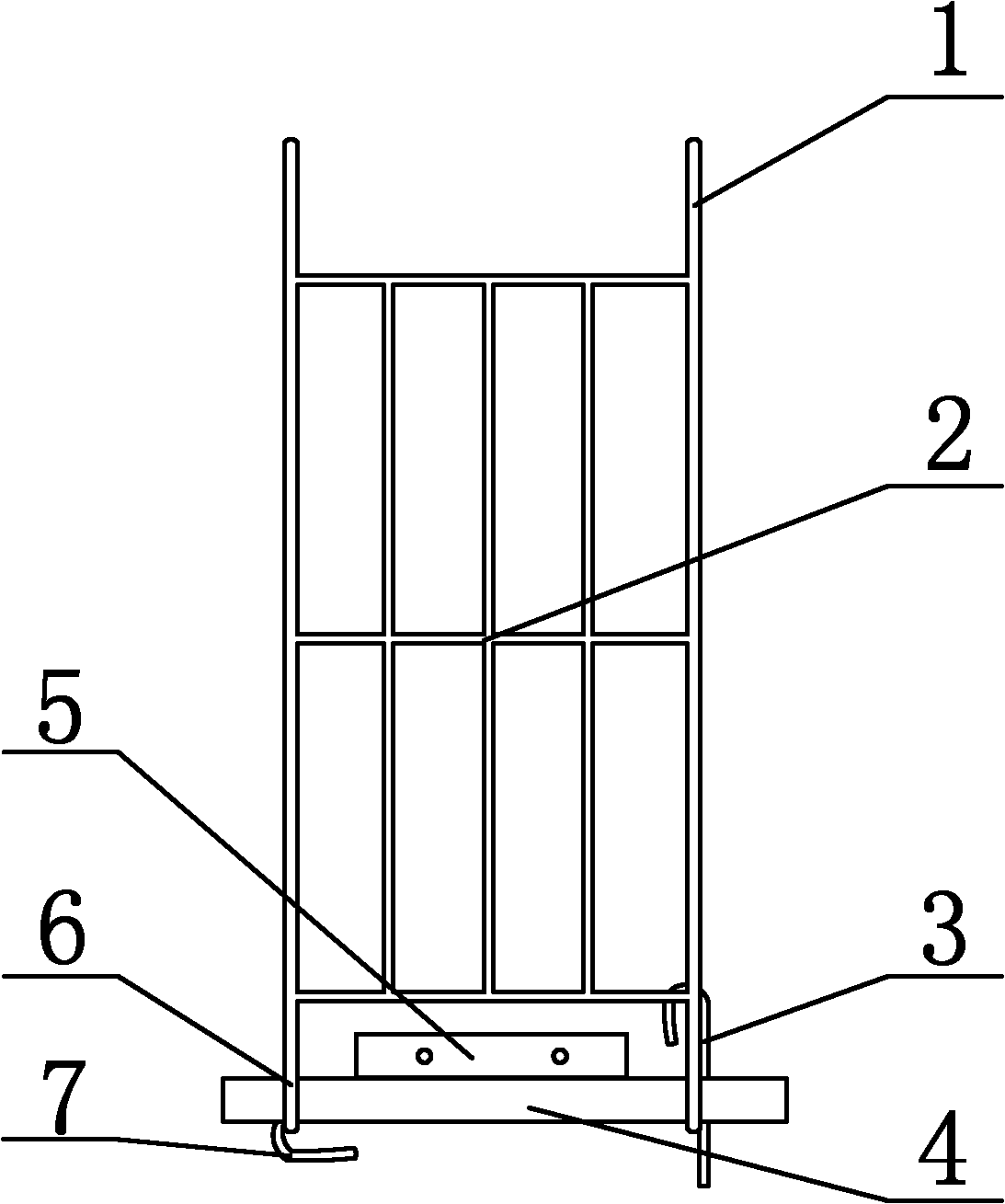

[0025] The vertical transport hanger provided by the invention has a structure such as Figure 1 to Figure 4 As shown, it is mainly composed of fence frame 2, load-bearing steel pipe 4 and hanging lugs connected with fence frame 2, wherein: the upper and bottom of fence frame 2 are open, and load-bearing steel pipe 4 is located at the opening at the bottom of fence frame 2 and is connected to The holes at the lower parts of the lifting lugs are movably connected.

[0026] The lifting lugs include the upper lifting lug 1 and the lower lifting lug 6, which form a closed rounded rectangle with the two vertical bars on the fence frame 2, and are made of round steel or screw steel with a diameter of 16mm. There are four closed rounded rectangles, which are symmetrically dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com