Automatic advancing and regressing transmission device of movable type doffing machine yarn pulling disc component

A doffer and mobile technology, which is applied to the field of the automatic in-out transmission device for the draw-off disc components of the mobile doffer, can solve the problems of not being fully automatic, uneconomical, and unable to be controlled by a program, so as to improve production efficiency and improve production efficiency. Economic benefits, accurate yarn drawing action, and easy program control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

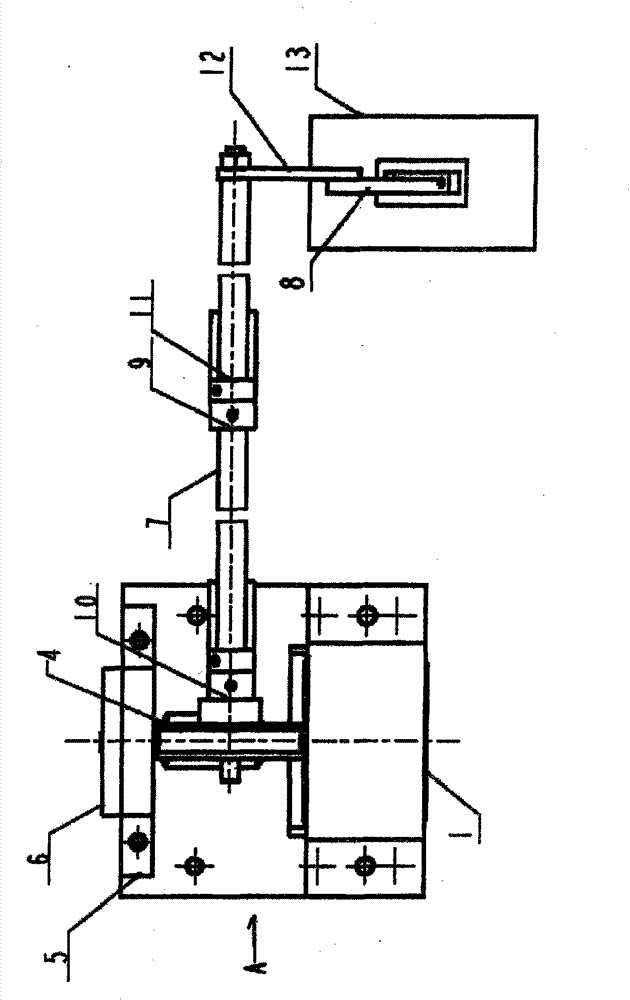

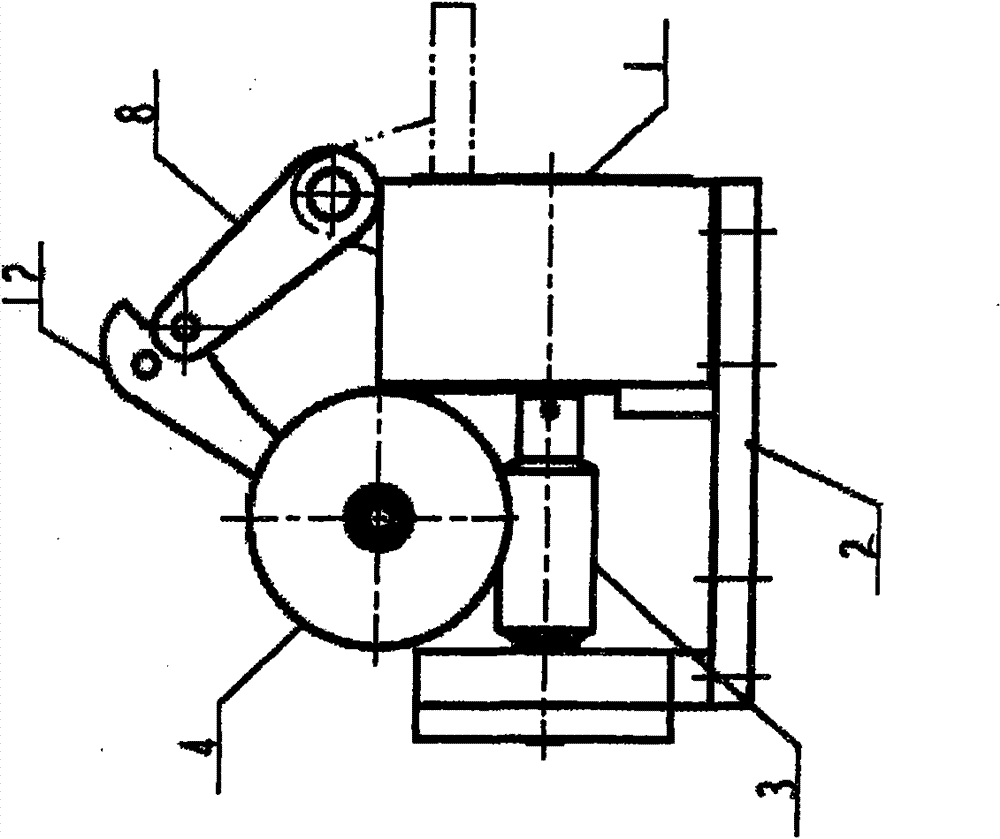

[0010] The micro-motor 1 controlled by the program can rotate forward and reversely, and the base plate 13 of the terminal part spinning disc component can be advanced and retreated through the transmission system, and automatically enters and exits the working position. The motor 1 drives the worm 3, the worm 3 drives the worm gear 4, and the worm gear 4 is fastened on the left end of the transmission long shaft 7, and the torque is transmitted to the connecting rod 12 fixedly mounted on the right end of the transmission long shaft 7 through the transmission long shaft 7, so that the connecting rod 12 is in the Synchronous rotation on the transmission long shaft 7 can make the crank 8 whose upper end is hinged with the connecting rod 12 follow up, and the other end of the crank 8 pushes or pulls the bottom plate 13 of the yarn pulling disc component to move on the moving guide rail below it, so that the yarn pulling The main parts such as the yarn-drawing disk and the pre-loos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com