Automobile filter element

A filter and filter element technology, applied in the direction of machines/engines, engine components, charging systems, etc., can solve the problems of increasing production costs of enterprises, wear of engine friction pairs, reducing filter paper filtration area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

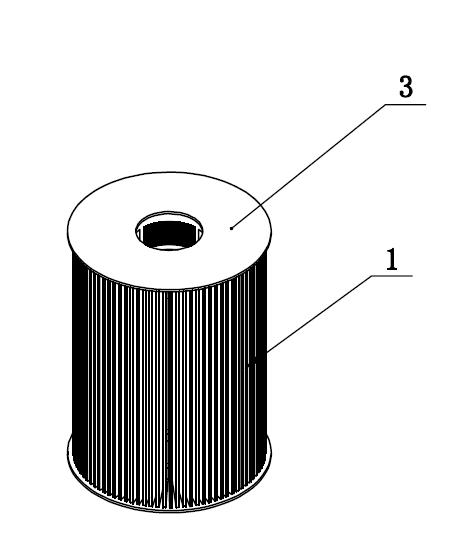

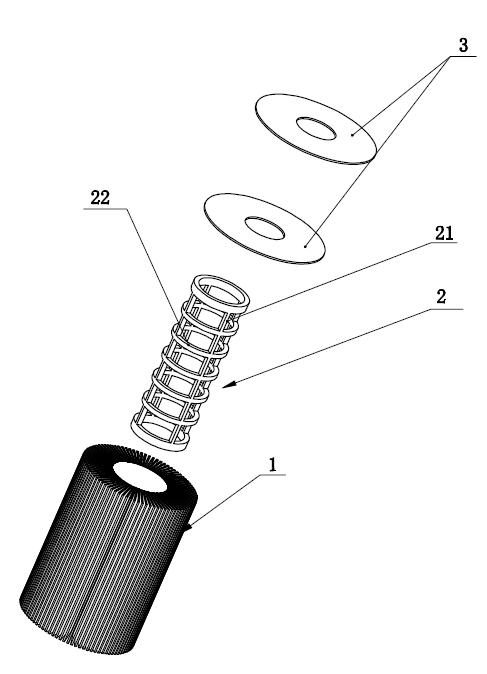

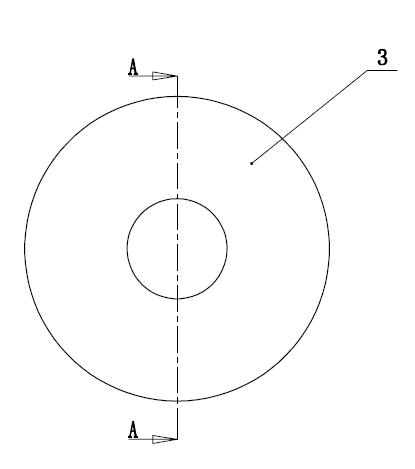

[0015] See attached figure 1 to attach Figure 4 , the automobile filter element disclosed by the present invention includes a hollow cylindrical body 1 formed by longitudinally folding filter paper material, and a skeleton 2 arranged in the hollow interior of the body, and two annular end faces are respectively arranged at both axial ends of the body 1, End caps 3 are respectively pasted on the two annular end surfaces, and the end caps 3 are made of non-woven fabric materials. By adopting the above-mentioned technical solution, the end cap 3 is made of non-woven fabric material, which saves material cost, and the non-woven fabric material has good sealing performance and anti-corrosion performance, and the non-woven fabric material is directly attached to the ring-shaped end surface, so that The processing is more convenient, and the non-woven fabric material is also waterproof. There is no need to set a sealing ring at the joint between the end cover 3 and the skeleton 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com