Method for preparing sulfide quantum dot co-sensitization porous titanium dioxide photoelectrode

A porous titanium dioxide and co-sensitization technology, applied in the field of solar cells, can solve the problems of inconvenient multi-quantum dot co-sensitization, not using battery optimization, rough methods, etc., to achieve improved photoelectric conversion efficiency, energy conversion efficiency, The effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Burn FTO to 450°C, spray 0.2mol / L isopropanol solution of diisopropyl di(acetylacetonate) titanate, keep it warm for 5 minutes, screen print titanium dioxide slurry after cooling, and burn at 450°C for 60 Minutes, the thickness is about 3 microns.

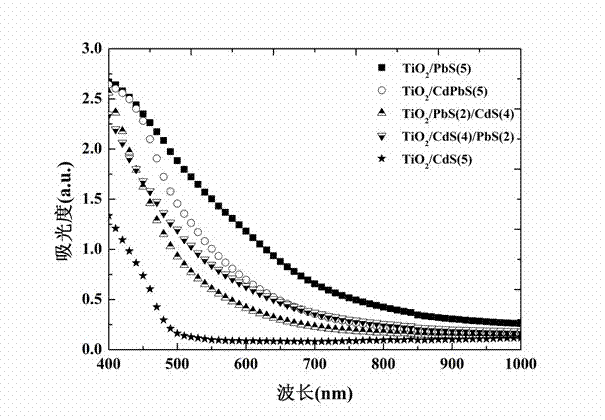

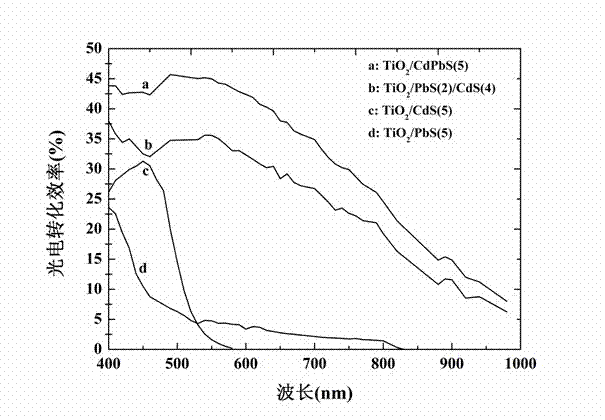

[0028] (2) Configure 0.45mol / L Cd(NO 3 ) 2 and 0.05mol / L Pb(NO 3 ) 2 The mixed aqueous solution A, 0.5mol / L Na 2 S methanol solution B, soak the porous titanium dioxide membrane in A for 5 minutes, rinse with ultrapure water, dry, soak in B for 5 minutes, rinse with methanol, dry, repeat 5 times. Vacuum drying at 100℃ for 1.5h to prepare sulfide quantum dot co-deposition sensitized porous titanium dioxide electrode TiO 2 / CdPbS(5).

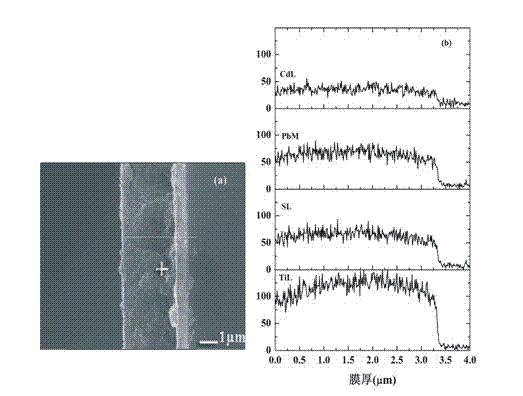

[0029] figure 1 It is a SEM-EDAX photo of the cross-section of lead sulfide and cadmium sulfide quantum dots on the titanium dioxide film. It can be seen from the figure that there are sulfur elements, lead elements and cadmium elements, which fully demonstrates the formation of lead ...

Embodiment 2

[0031] (1) Burn FTO to 400°C, spray 0.1mol / L isopropanol solution of diisopropyl di(acetylacetonate) titanate, keep it warm for 20 minutes, screen print titanium dioxide slurry after cooling, and burn at 480°C for 40 Minutes, the thickness is about 3 microns.

[0032] (2) Configure 0.45mol / L Cd(NO 3 ) 2 and 0.05mol / L Pb(NO 3 ) 2 The mixed aqueous solution A, 0.5mol / L Na 2 S methanol solution B, soak the porous titanium dioxide membrane in A for 5 minutes, rinse with ultrapure water, dry, soak in B for 5 minutes, rinse with methanol, dry, repeat 4 times. Vacuum drying at 100℃ for 1.5h to prepare sulfide quantum dot co-deposition sensitized porous titanium dioxide electrode TiO 2 / CdPbS(4).

Embodiment 3

[0034] (1) Burn FTO to 500°C, spray 0.4mol / L isopropanol solution of diisopropyl di(acetylacetonate) titanate, keep it warm for 10 minutes, screen print titanium dioxide slurry after cooling, and burn at 500°C for 30 Minutes, the thickness is about 3 microns.

[0035] (2) Configure 0.45mol / L Cd(NO 3 ) 2 and 0.05mol / L Pb(NO 3 ) 2 The mixed aqueous solution A, 0.5mol / L Na 2 S methanol solution B, soak the porous titanium dioxide membrane in A for 5 minutes, rinse with ultrapure water, dry, soak in B for 5 minutes, rinse with methanol, dry, repeat 6 times. Vacuum drying at 100℃ for 1.5h to prepare sulfide quantum dot co-deposition sensitized porous titanium dioxide electrode TiO 2 / CdPbS(6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com