Negative electrode for nonaqueous electrolyte secondary batteries and lithium ion secondary battery

A non-aqueous electrolyte, secondary battery technology, applied in battery electrodes, secondary batteries, batteries, etc., to achieve the effects of low volume expansion, high battery capacity, and high ring charge/discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Preparation of conductive particles

[0072] The average particle size of 100g is 5μm, and the BET specific surface area is 3.5m 2 / g silicon oxide SiO x (x = 1.01) The pellets were loaded into a batch furnace. The furnace was evacuated by means of an oil-sealed rotary vacuum pump while heating the furnace to 1,100°C. Once this temperature is reached, the CH 4 Gas was passed into the furnace at 0.3 NL / min, where the carbon coating process was carried out for 5 hours. A reduced pressure of 800 Pa was maintained during the treatment. At the end of the treatment, the furnace was cooled and 97.5 g of black particles were recovered, i.e. with SiO dispersed in 2 Carbon-coated particles in Si. The black particles have an average particle size of 5.2 μm and a BET specific surface area of 6.5 m 2 / g, these particles are electrically conductive due to the 5.1 wt% carbon-coated coating based on the black particles.

[0073] Preparation of polyamide-imide resin soluti...

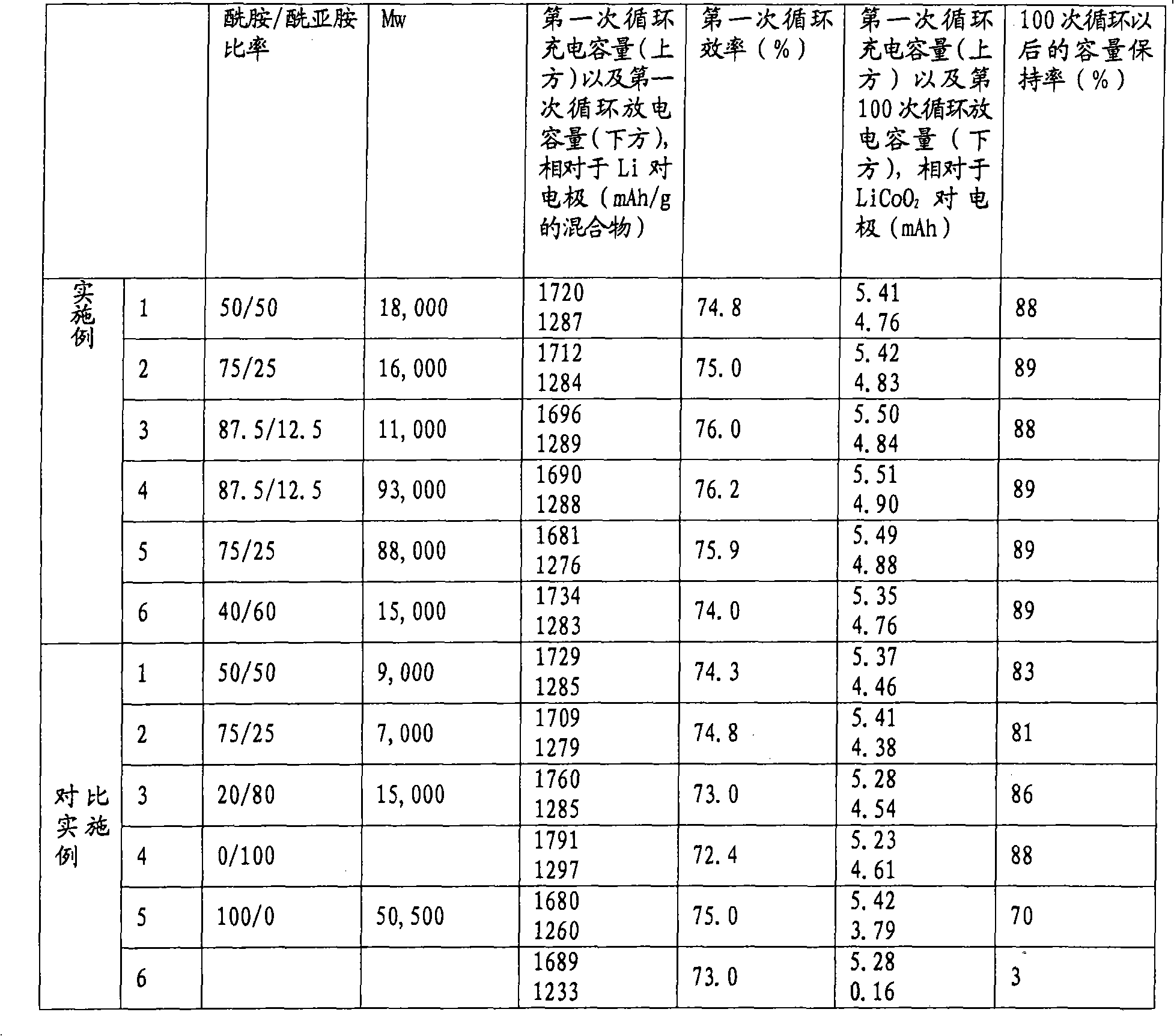

Embodiment 2

[0085] Preparation of polyamide-imide resin solution with amide / imide ratio of 75 / 25

[0086] Prepare the polyamide / imide resin solution as in Example 1, except that 96.0 g (0.5 moles) of trimellitic anhydride is used as the polyfunctional carboxylic acid anhydride, and 83.0 g (0.5 moles) of isophthalic acid is used as the polyfunctional anhydride. Carboxylic acid, 250.0 g (1.0 mol) of 4,4'-diphenylmethane diisocyanate as polyfunctional isocyanate, and 708 g of NMP. The battery test was performed as in Example 1, except that the polyamide / imide resin solution prepared here was used. The results are also reported in Table 1.

Embodiment 3

[0088] Preparation of polyamide-imide resin solution with amide / imide ratio of 87.5 / 12.5

[0089] The polyamide / imide resin solution was prepared as in Example 1, except that 48.0 g (0.25 moles) of trimellitic anhydride was used as the polyfunctional carboxylic anhydride, and 124.5 g (0.75 moles) of isophthalic acid was used as the polyfunctional anhydride. Carboxylic acid, 250.0 g (1.0 mol) of 4,4'-diphenylmethane diisocyanate as polyfunctional isocyanate, and 708 g of NMP. The battery test was performed as in Example 1, except that the polyamide / imide resin solution prepared here was used. The results are also reported in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap