Planting method and equipment for shallow plowing, weeding, ditching and soil covering

A technology of covering soil and equipment, which is applied in the field of mechanized planting of rapeseed, can solve the problems of high cost, affecting the number of seedlings, rowing, and uniformity of seedlings, etc., so as to improve fertility, reduce the total amount of fertilizer, Good for root growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

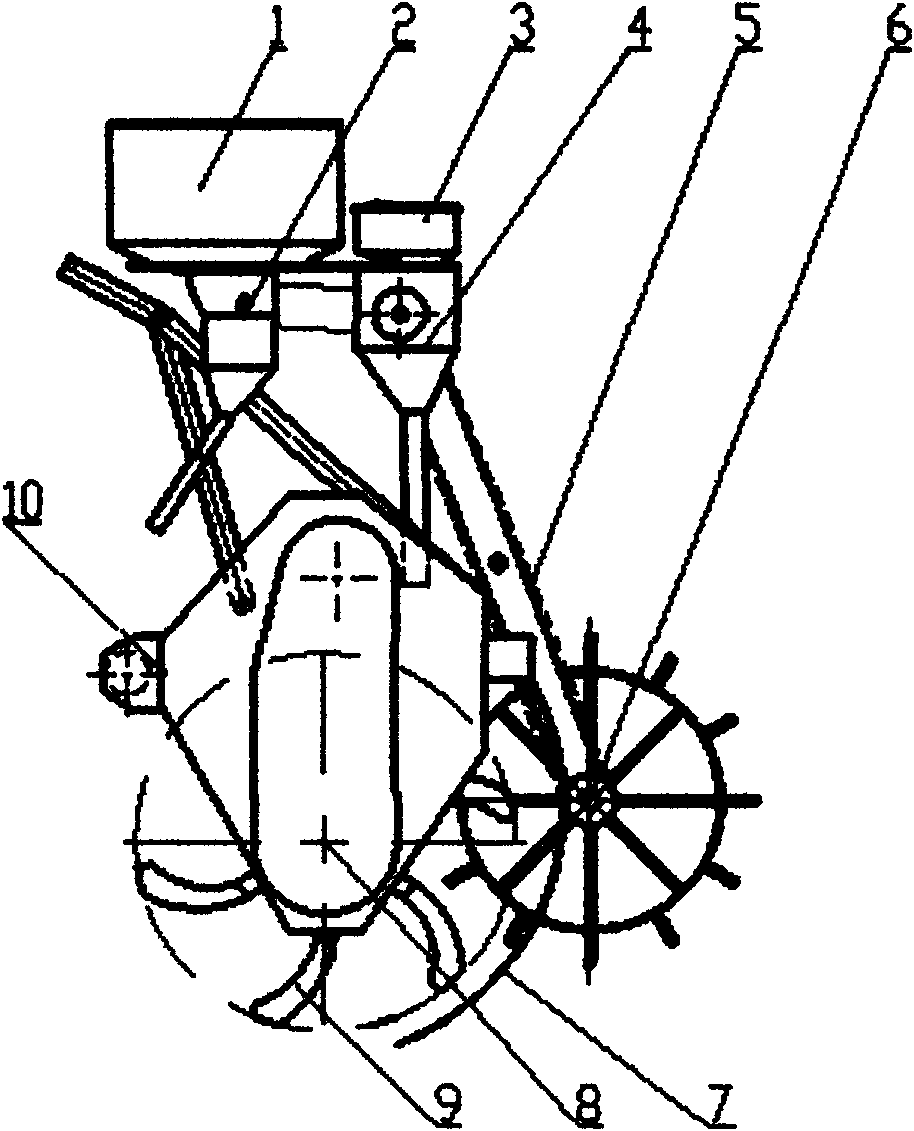

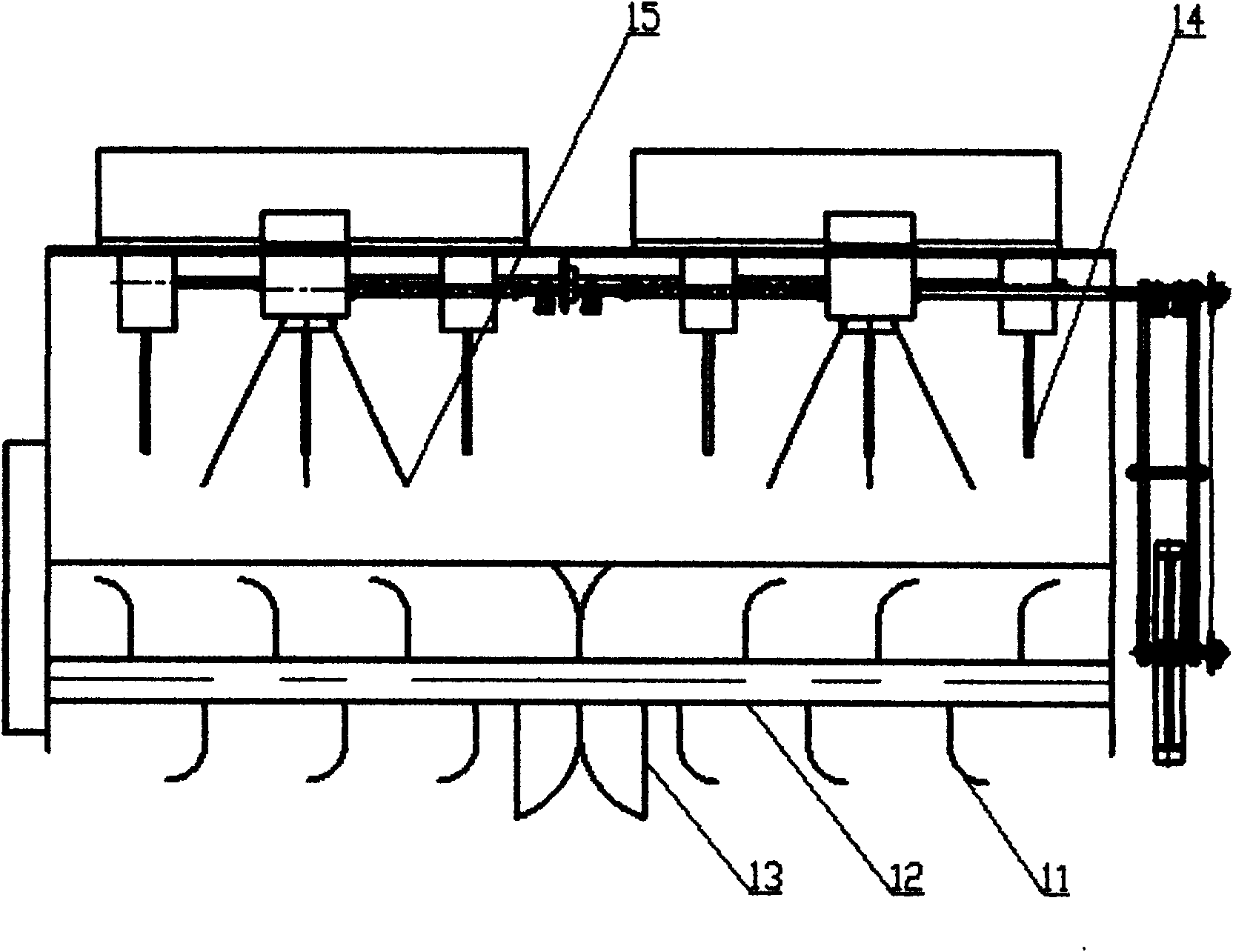

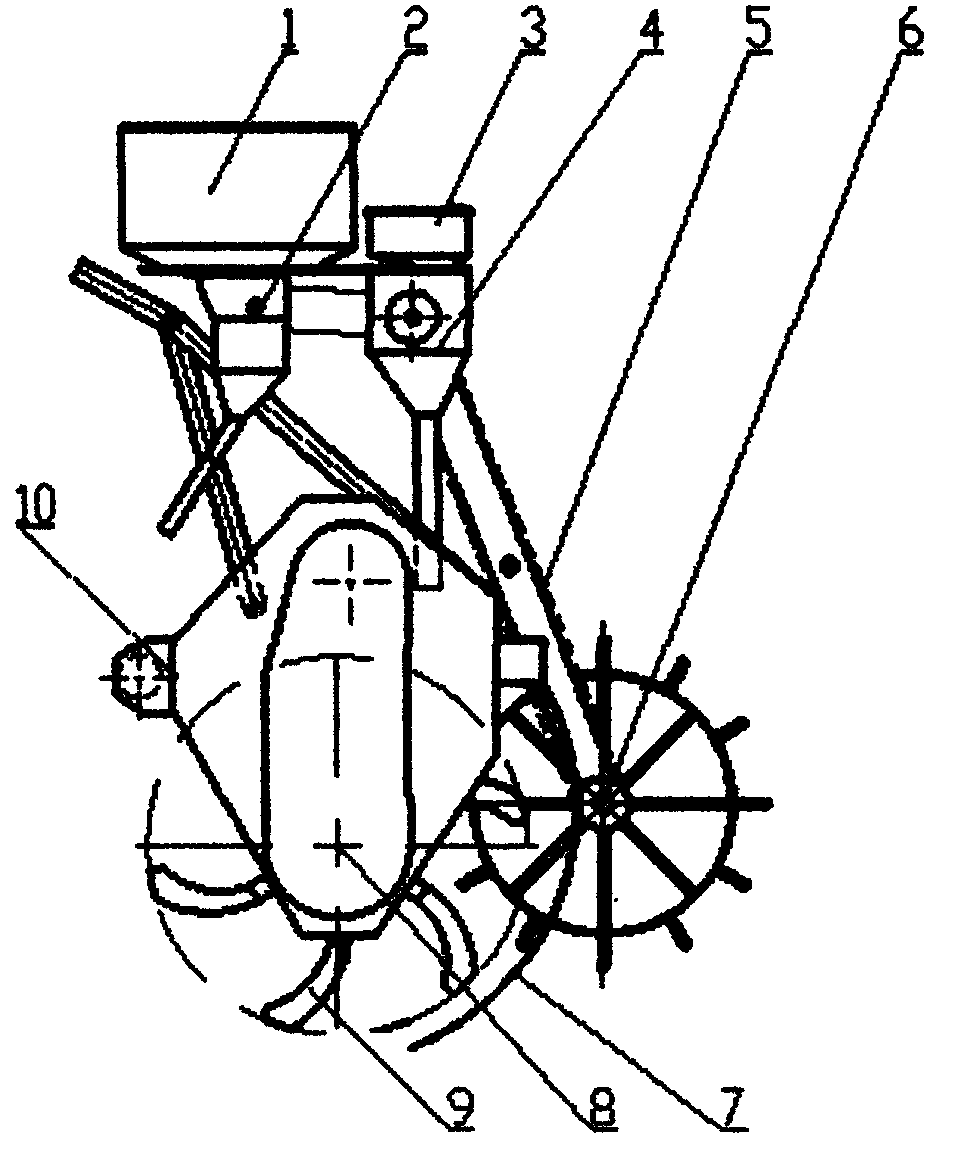

[0023] refer to figure 1 , figure 2 , a planting equipment for shallow tillage, weeding, ditching, ditching and soil covering mainly consists of a fertilizer box [1], a fertilizer discharger [2], a seed box [3], a seed metering device [4], a transmission chain for seed and fertilizer discharge [5], and a ground wheel [6], ditching shovel [7], side drive chain box [8], ditching knife [9], shallow tillage ditching frame [10], shallow tillage knife [11], shallow tillage knife shaft [ 12], ditching cutter head [13], fertilizer discharge pipe [14], seed discharge pipe [15] form.

[0024] Through the ground wheel [6] and the seed and fertilizer discharge chain [5], the seed and fertilizer discharge device [4] is driven to perform seed and fertilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com