Electric pressure steamer

An electric steamer and pressure technology, applied in pressure cookers, steam cooking utensils, etc., can solve the problems of slow steam speed, high water consumption, steam leakage, etc., and achieve the effect of increased cooking speed, less water consumption and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

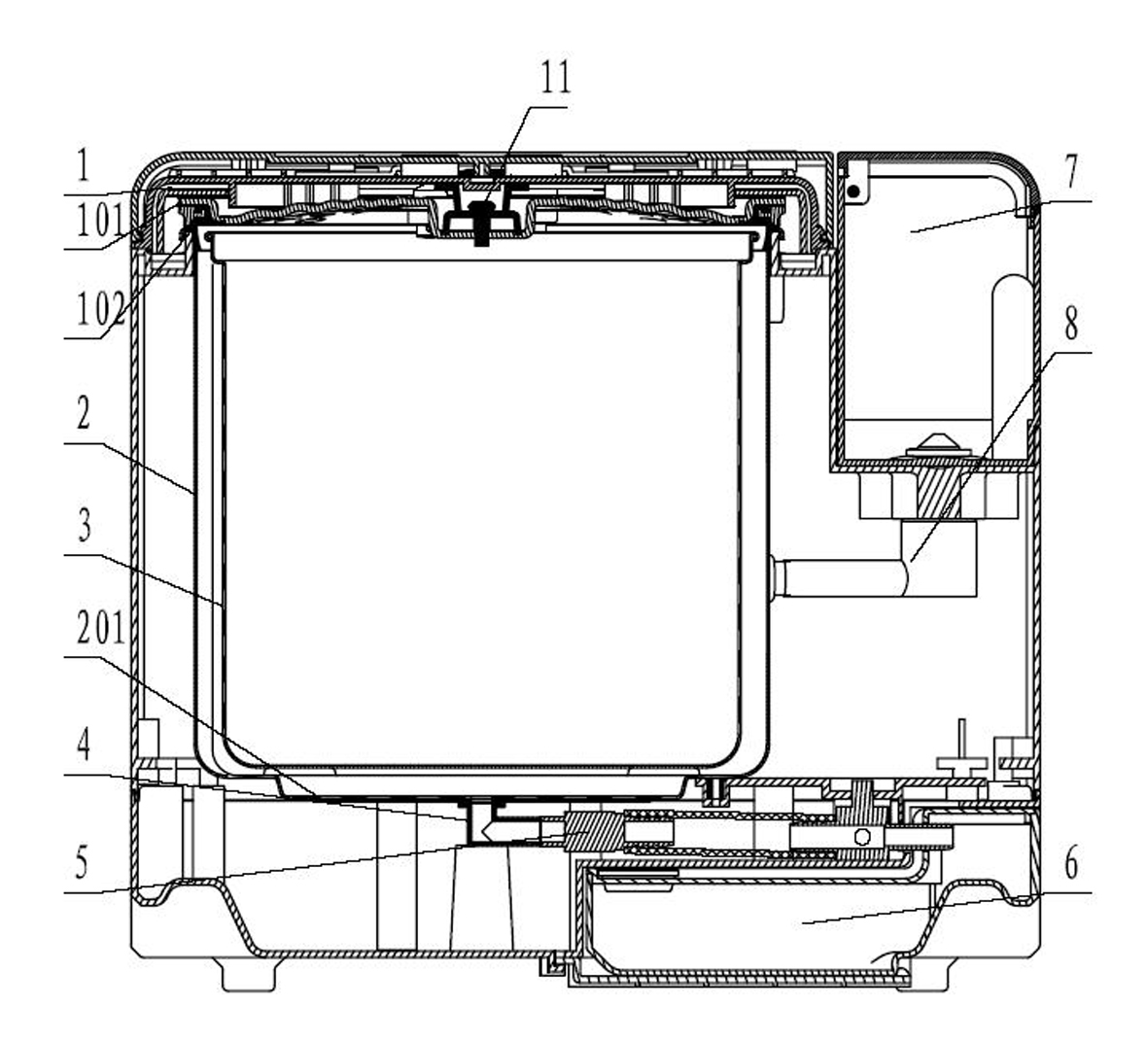

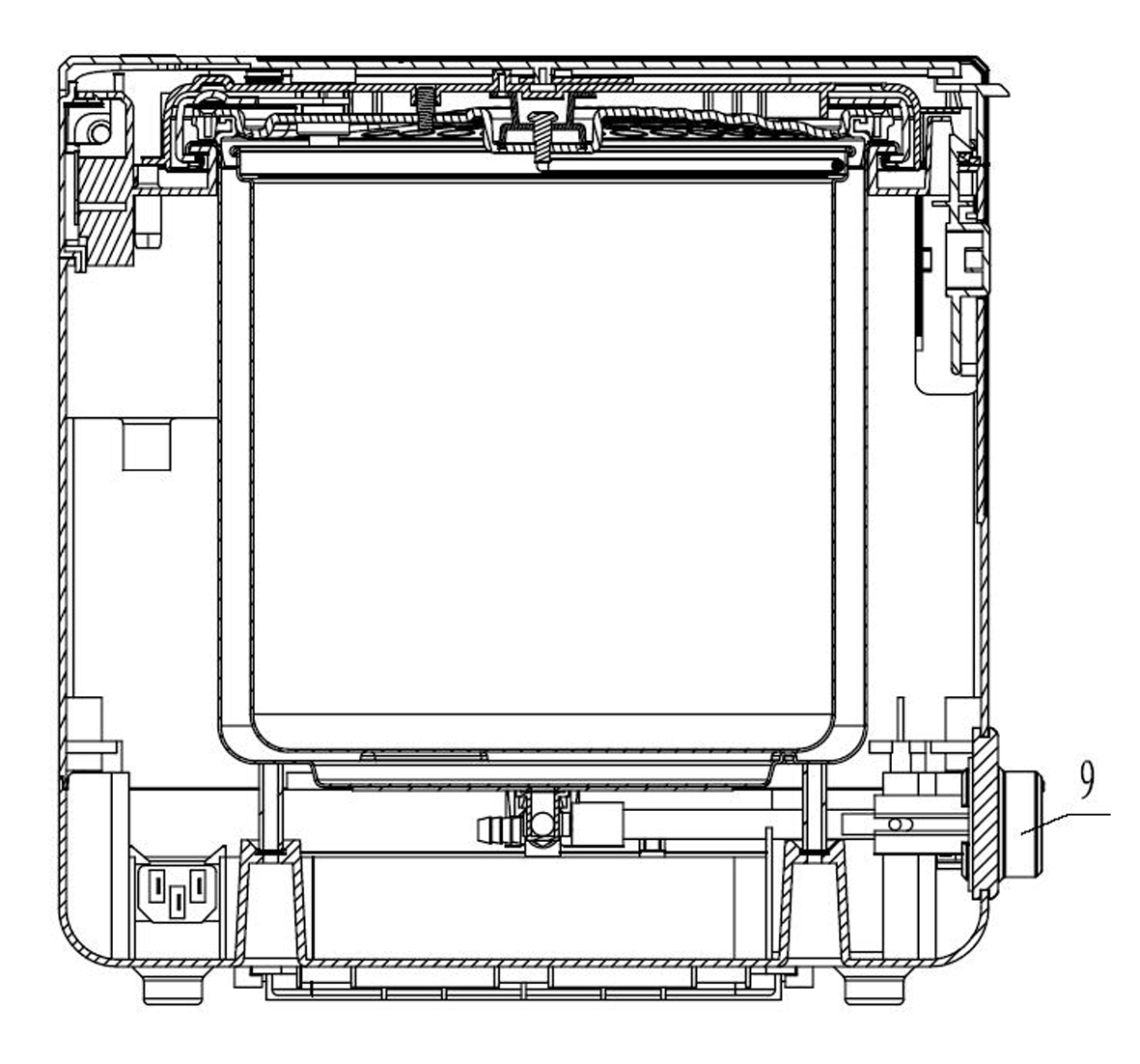

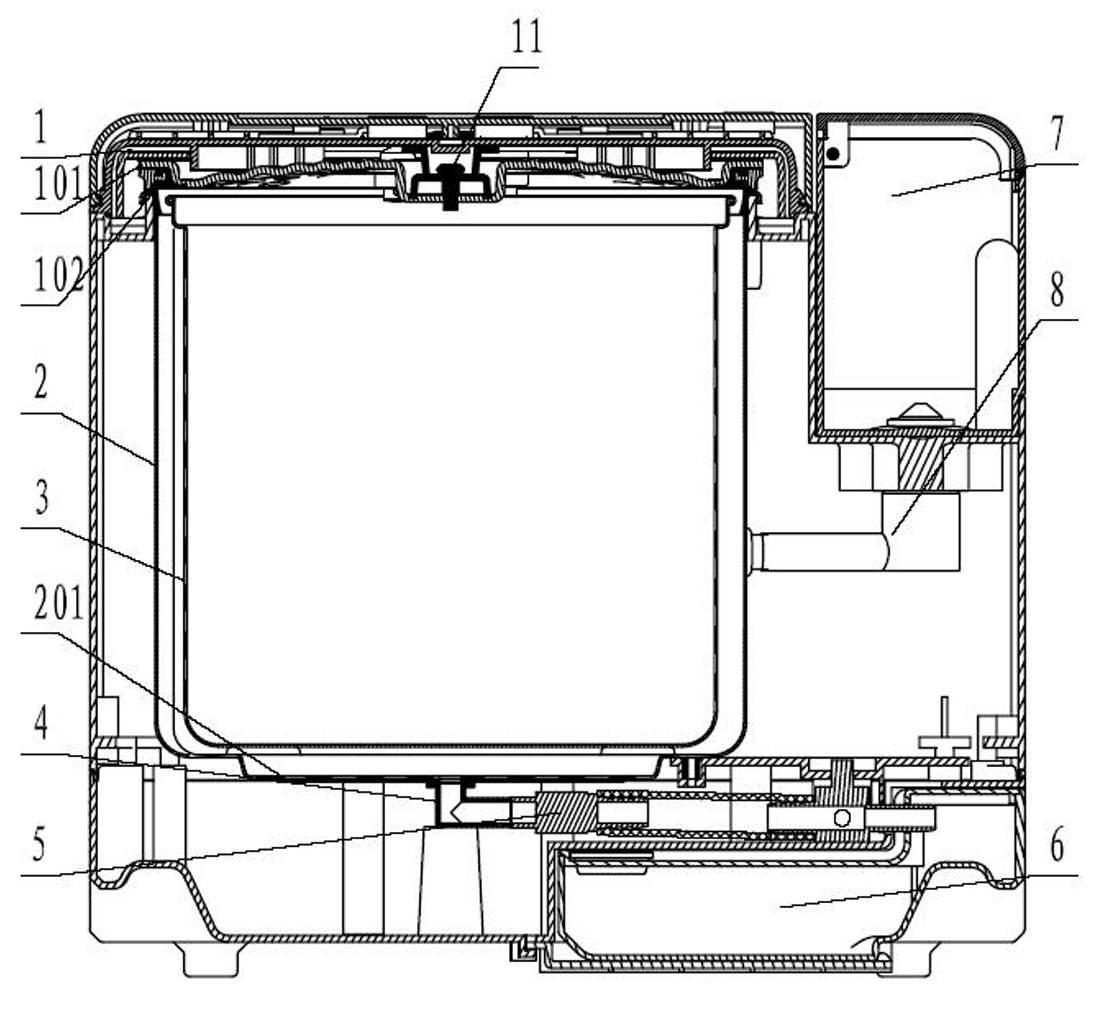

[0030] The pressure electric steamer of present embodiment, see figure 1 with figure 2 As shown, it includes an outer pot 2 inside the pot body, an inner pot 3 placed inside the outer pot for cooking food, a pot lid 101 fastened on the outer pot, a water tank 7 for containing water sources, and an electric heating element at the bottom of the outer pot 201 and the control circuit for controlling the electric heating device, different from the traditional pressure electric steamer, the present invention is provided with a sealing ring between the pot cover 101 and the outer pot 2, the sealing ring is as figure 1 The shown card is placed in the groove on the edge of the pot cover 101, the outer edge of the section of the sealing ring is attached to the inner surface of the outer pot mouth, and the upper cover 1, the pot cover 101 and the outer pot are sealed and locked with each other through the lock buckle and the sealing ring. The distance between the pressure chamber, the ...

Embodiment 2

[0039] The difference from Embodiment 1 is that there is a cavity inside the drainage box body 6, and the cavity is filled with a condensing agent, which can be various commercially available reagents for liquid condensation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com