Post-forging heat-insulating protective guard of 2000T high-speed forging press

A shield and forging technology, applied in metal processing equipment and other directions, can solve the problems of delayed production scheduling, inability to enter the tempering furnace in time, and long heat treatment time period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

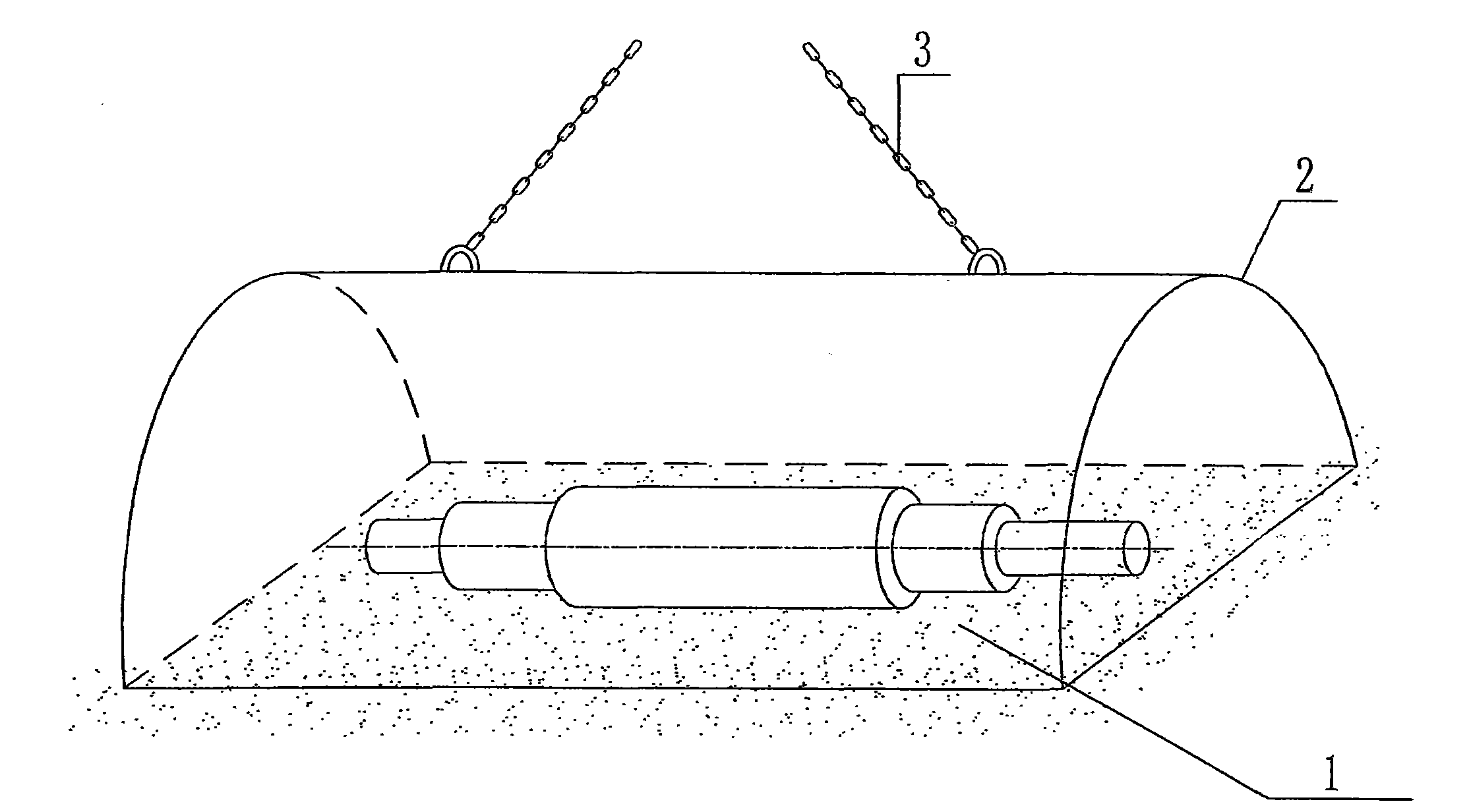

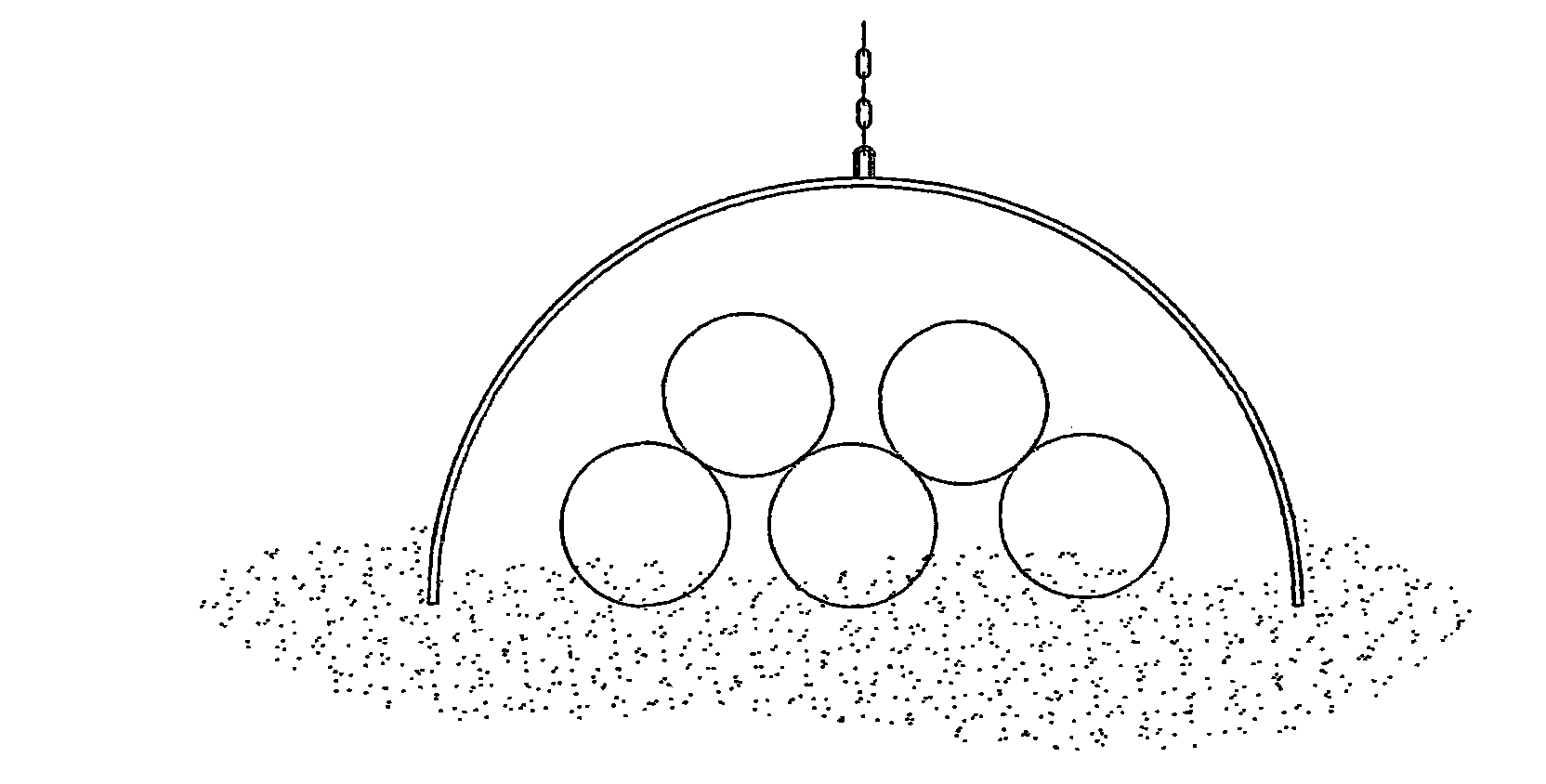

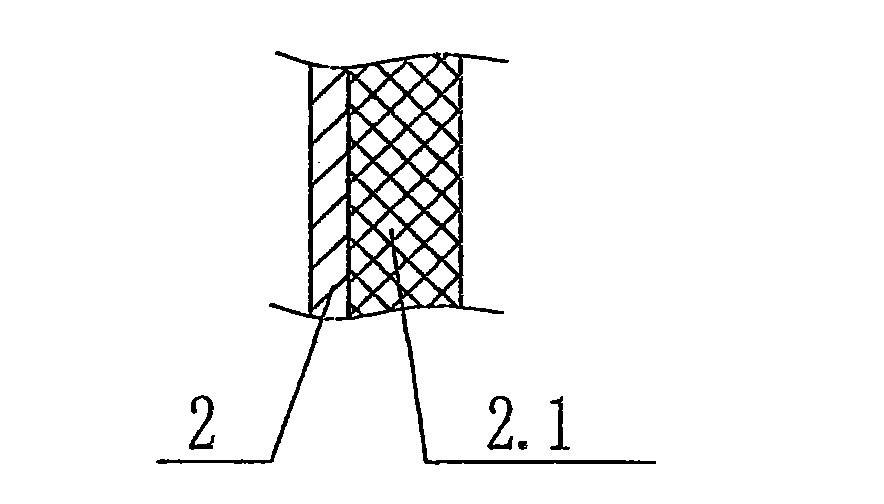

[0009] see Figure 1~2 , The 2000T quick forging machine that the present invention relates to after forging heat-preservation shield, mainly is made up of three parts of bunker 1, shield 2 and chain 3 with hook. The shield 2 is in the shape of a horizontal semi-cylindrical, and the inner wall of the shield 2 is covered with a fire-resistant and heat-insulating material 2.1, such as image 3 . The shield 2 is fastened above the bunker 1, and the chain 3 with a hook is arranged on the top of the shield 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com