Biaxial orientation processing equipment for thermoplastic plastic pipe

A thermoplastic biaxial orientation technology, applied in the field of thermoplastic pipe biaxial orientation processing equipment, can solve the problems of high equipment cost and complex biaxial orientation processing device, and achieve low cost, easy control of heating temperature and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

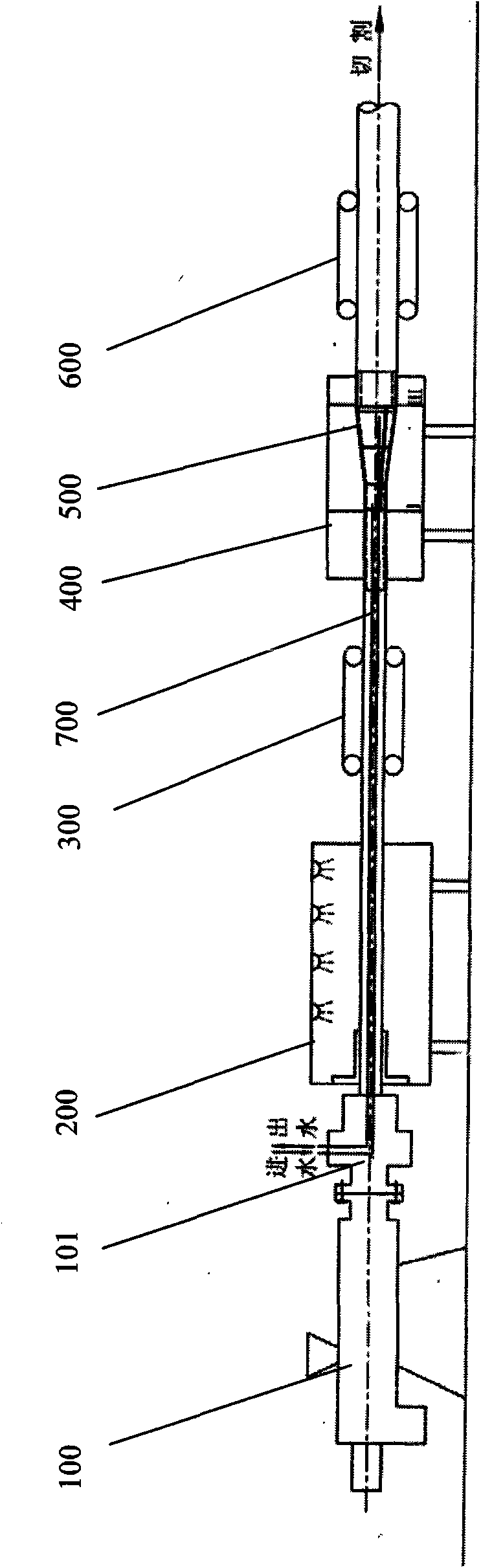

[0017] Such as figure 1 As shown, the thermoplastic pipe biaxial orientation processing equipment of the present invention includes an extruder 100 equipped with a pipe extrusion die, a cooling device 200, a front traction device 300, a water tank 400, an expanding mandrel 500, and a rear traction device 600 and hollow connecting rod 700.

[0018] Wherein, the extruder 100, the cooling device 200, the front traction device 300, the water tank 400, and the rear traction device 600 are arranged in sequence according to the pipe processing flow. The cooling device 200 is a vacuum spray cooling sizing box, the expansion mandrel 500 is set in the water tank 400 , and the hollow connecting rod 700 is connected between the expansion mandrel 500 and the die head 101 of the extruder 100 .

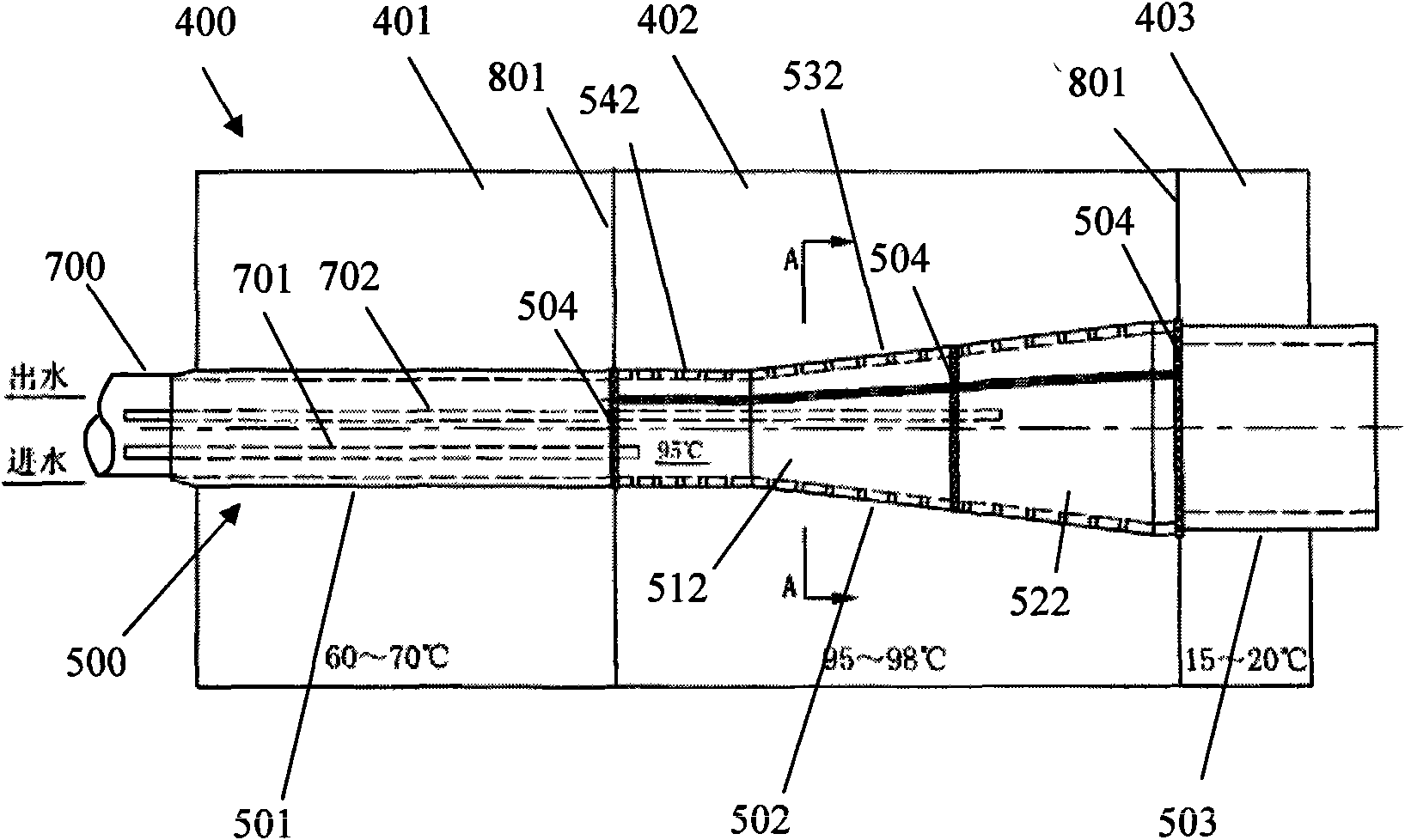

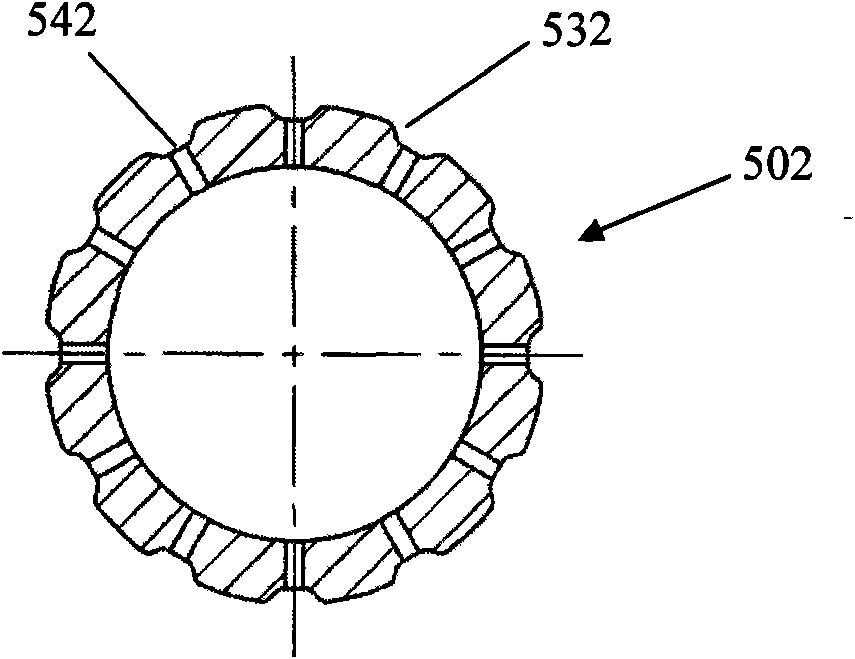

[0019] Such as figure 2 As shown, the water tank 400 is divided into three areas, namely a preheating area 401 , a heating area 402 and a cooling area 403 , and the areas are isolated by a heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com