Building block forming equipment for industrial waste residues

A technology for forming equipment and industrial waste residues, which is applied in the field of block forming equipment for industrial waste residues, can solve the problems of low mechanical strength of blocks, uneven mixing of components, insufficient bonding of blocks, etc., to ensure mechanical properties and improve Adhesiveness and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

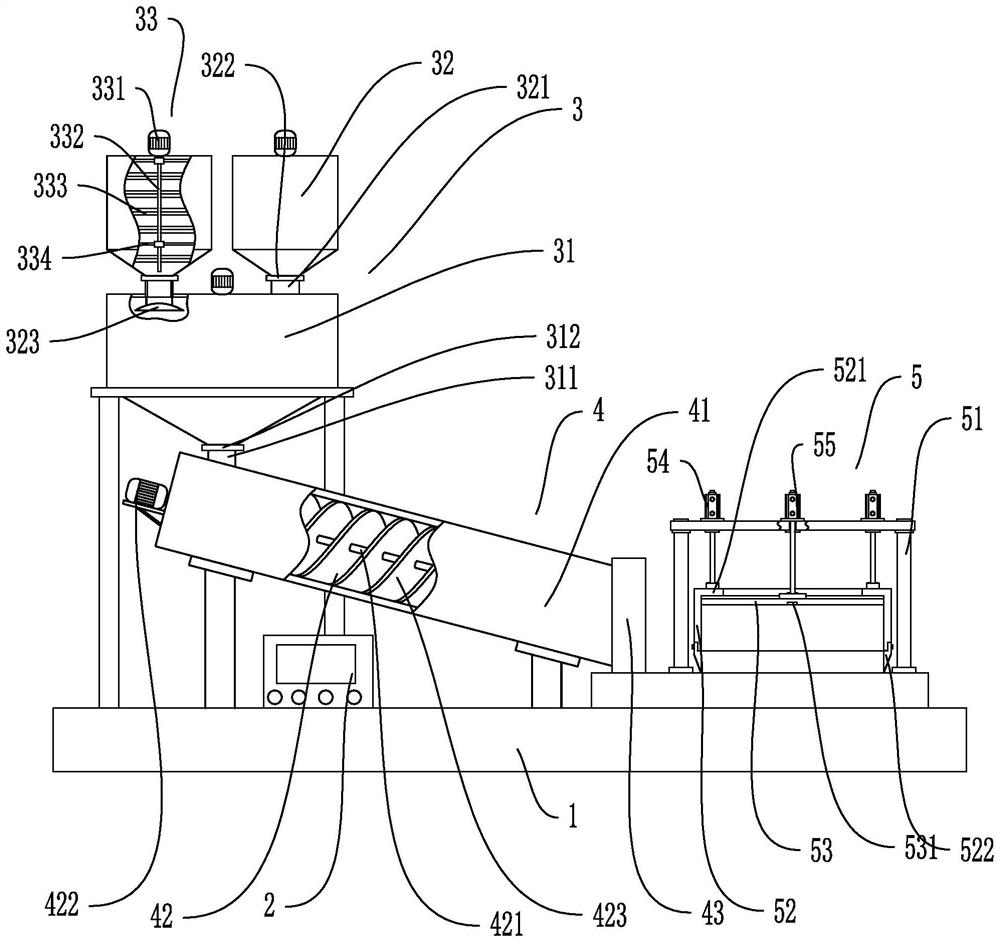

Examples

Embodiment 2

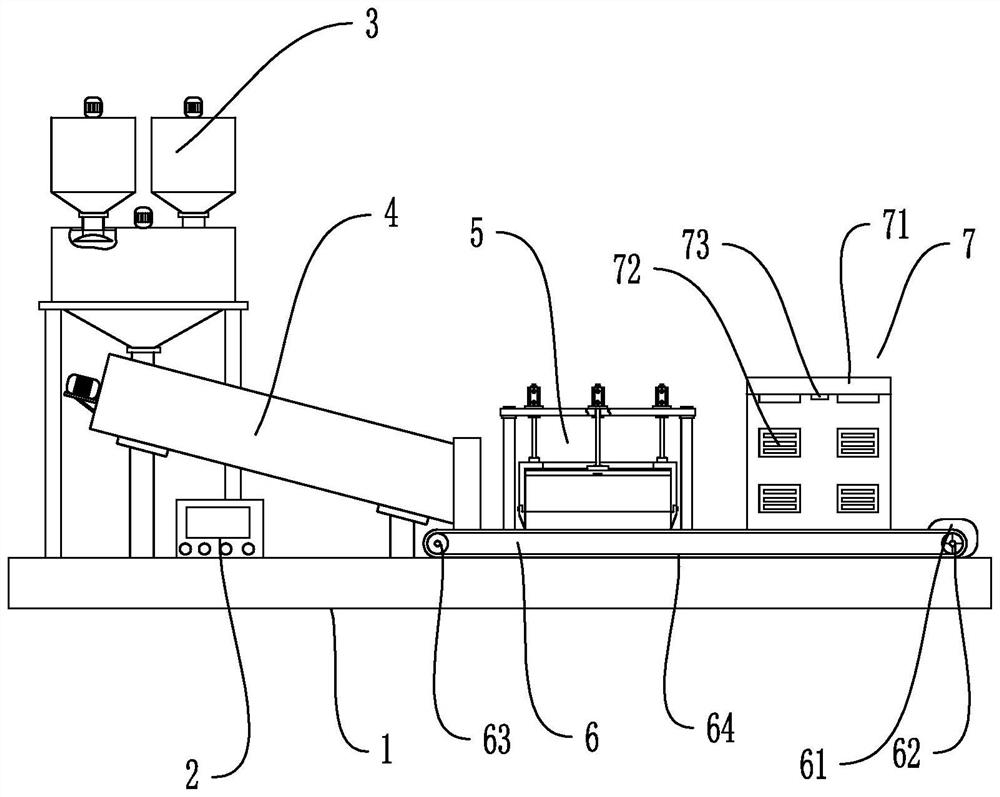

[0043] Embodiment two, on the basis of embodiment one, such as figure 2 As shown, the base 1 is also provided with a transmission mechanism 6 adapted to the pressing mechanism 5. The transmission mechanism 6 includes a transmission motor 61, a transmission main shaft 62, a transmission slave shaft 63 and a transmission belt 64; the transmission mechanism 6. It is convenient for the formed blocks to be conveyed, and the conveyor belt 64 is driven by the conveying motor 61 to move, so that the pressing mechanism 5 presses and cuts the blocks to be conveyed on the conveyor belt 64.

[0044] Such as figure 2 As shown, the base 1 is provided with a heating mechanism 7 that is compatible with the transmission mechanism 6. The heating mechanism 7 includes a heating bracket 71 that spans both sides of the conveyor belt 64. The heating bracket 71 is in the shape of a Chinese character. The structure is set, and the left and right sides and the upper side of the heating bracket 71 ar...

Embodiment 3

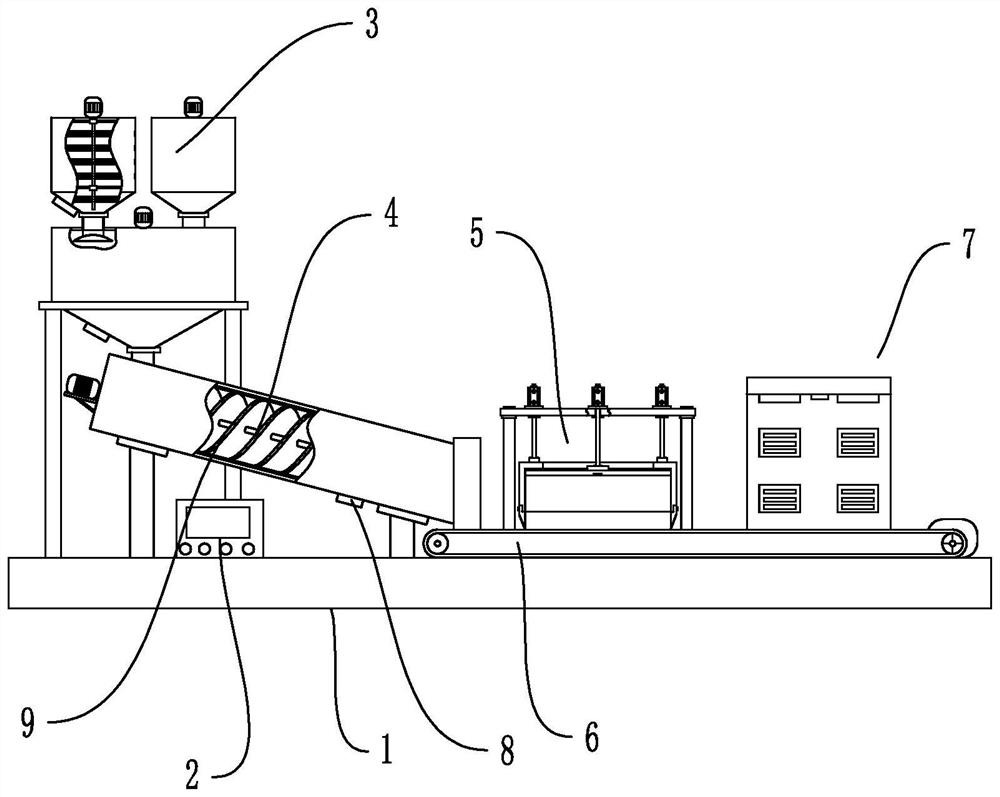

[0046] Embodiment three, on the basis of embodiment two, such as image 3 As shown, vibrators 8 are arranged on the outside of the raw material box 32, the storage barrel 31 and the forming barrel 41, and the inner walls of the stock barrel 31 and the forming barrel 41 as well as the stirring blade 333 and the extruding blade 423 All are equipped with electric heating structures 9, which are set as electric heating wires; the vibrator 8 can prevent material blockage during material transfer, ensure the normal operation of the whole equipment, and effectively improve the production efficiency of blocks. The electric heating structures 9 can Prevent the material from coagulating and ensure the smooth forming of the block.

[0047] In summary, the present invention has the following beneficial effects:

[0048] 1. By setting the raw material box 32 on the upper side of the material storage barrel 31, there is no need to carry out mixing and mixing, and the material is directly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com