Automobile dashboard crossbeam transfer device

A technology for automobile dashboards and transfer devices, which is applied in the directions of transportation and packaging, packaging, and external frames, and can solve problems such as high storage costs, high logistics costs, and large volumes of instrument panel beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

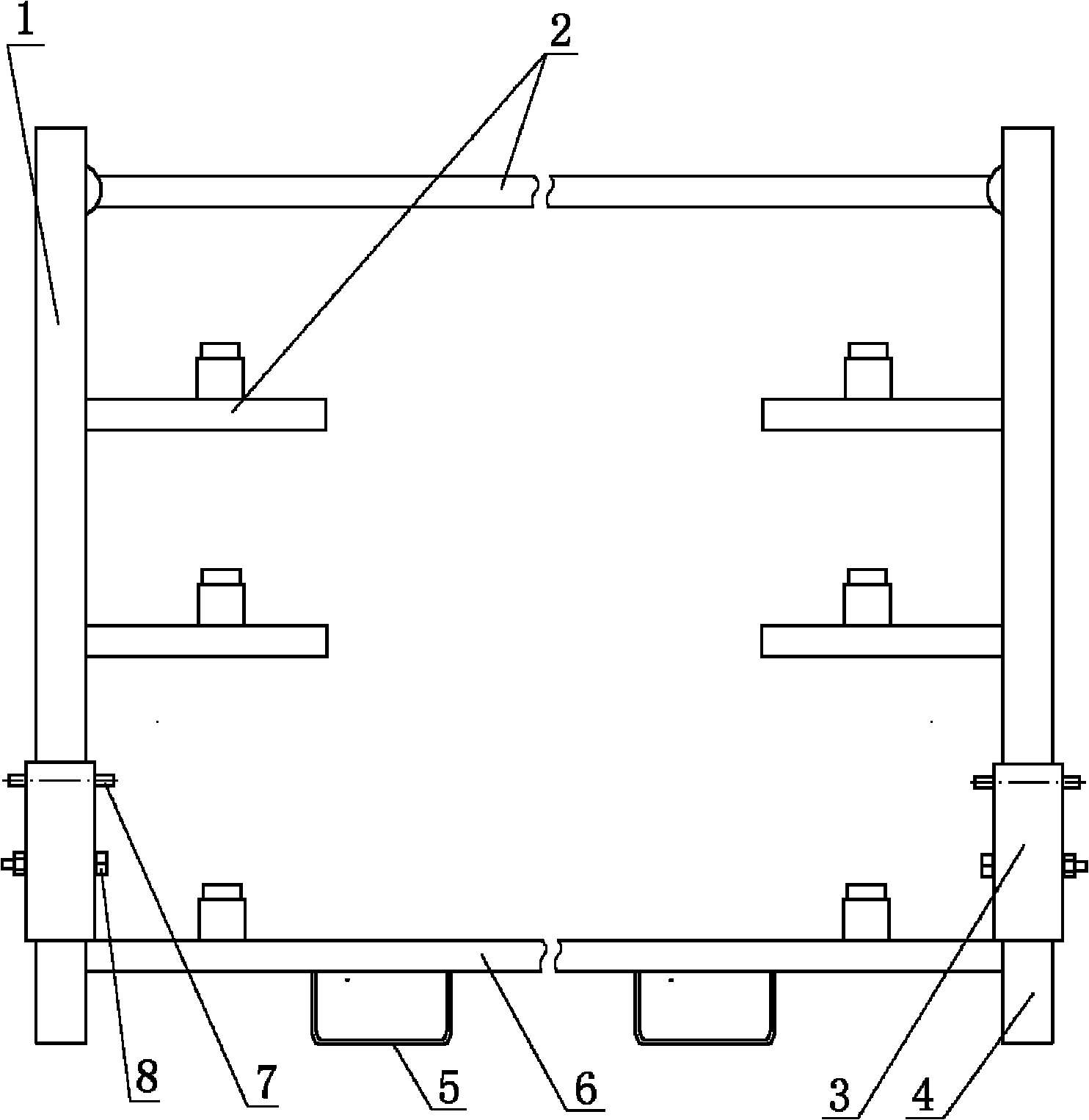

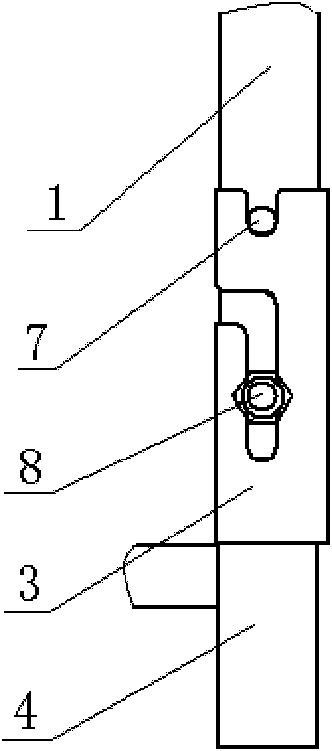

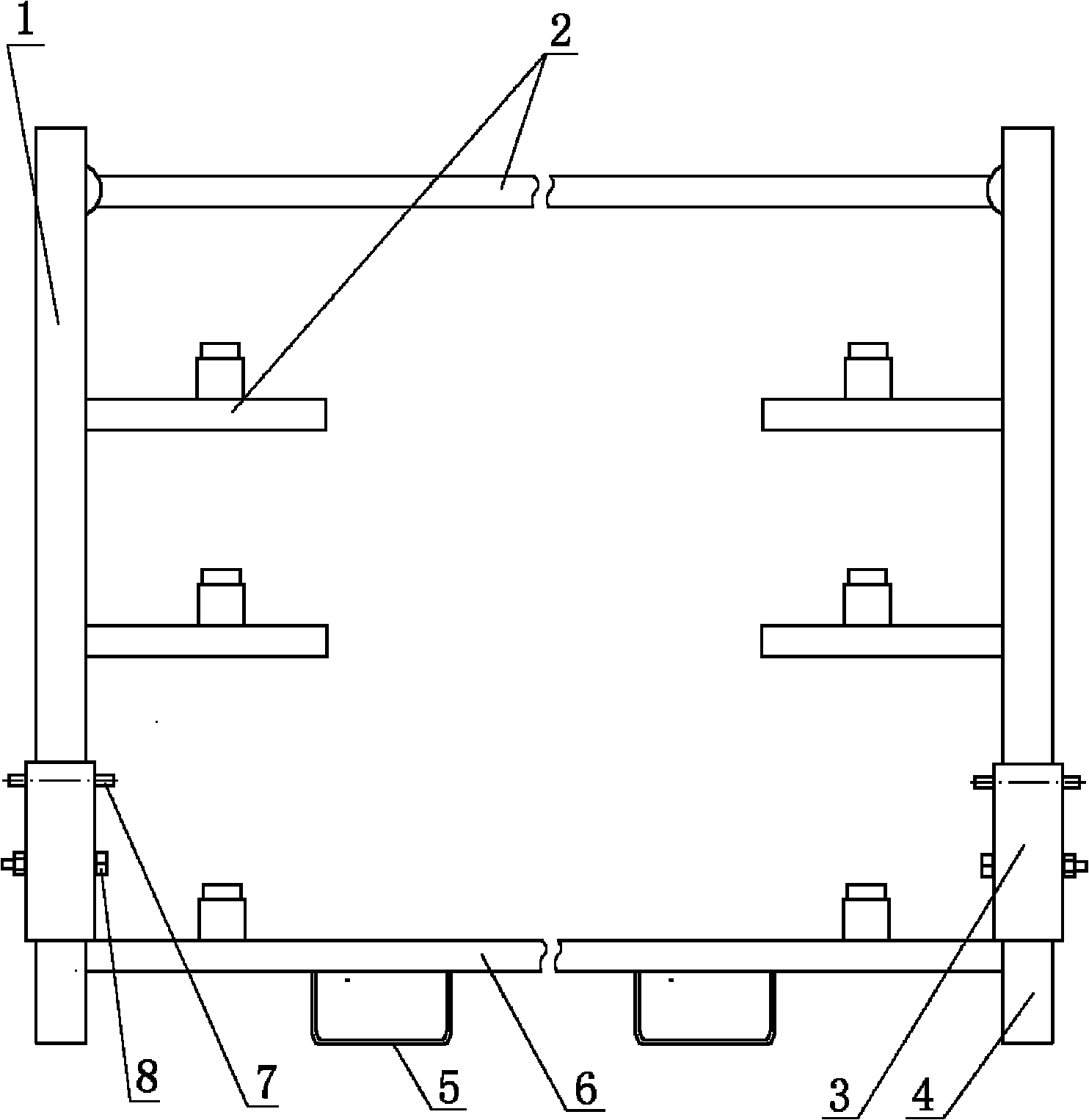

[0012] Such as figure 1 , figure 2 As shown, the automobile instrument panel beam transfer device is composed of a chassis and a support frame, the chassis includes a chassis frame body 6, four chassis columns 4 and four column connectors 3, and the support frame includes a support frame body 2 and four A support frame column 1, the bottom of the base frame frame body 6 has a support member 5, and the top of each base frame column 4 has a column connector that is integrated, and each support frame column of the support frame and the corresponding column of the base frame The connecting piece is rotatably connected. Each support frame column 1 is a square tube structure, each base frame column is a square tube structure, and the column connector is a channel steel structure. The bottom of each support frame column 1 has a bolt and nut 8 that passes through the support frame column 1 horizontally And the support pin 7 that is horizontally fixed on the support frame column 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com