Method and device for designing radiating down lamp structure of light-emitting diode (LED) integrated light source

A technology of structural design and heat dissipation cylinder, which is applied in the structural design method of heat dissipation downlights and the field of downlights manufactured by this method, can solve the problems of energy waste, aesthetic discount, and the volume cannot be made too large, so as to reduce the transmission barrier, Beautiful appearance and improved heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

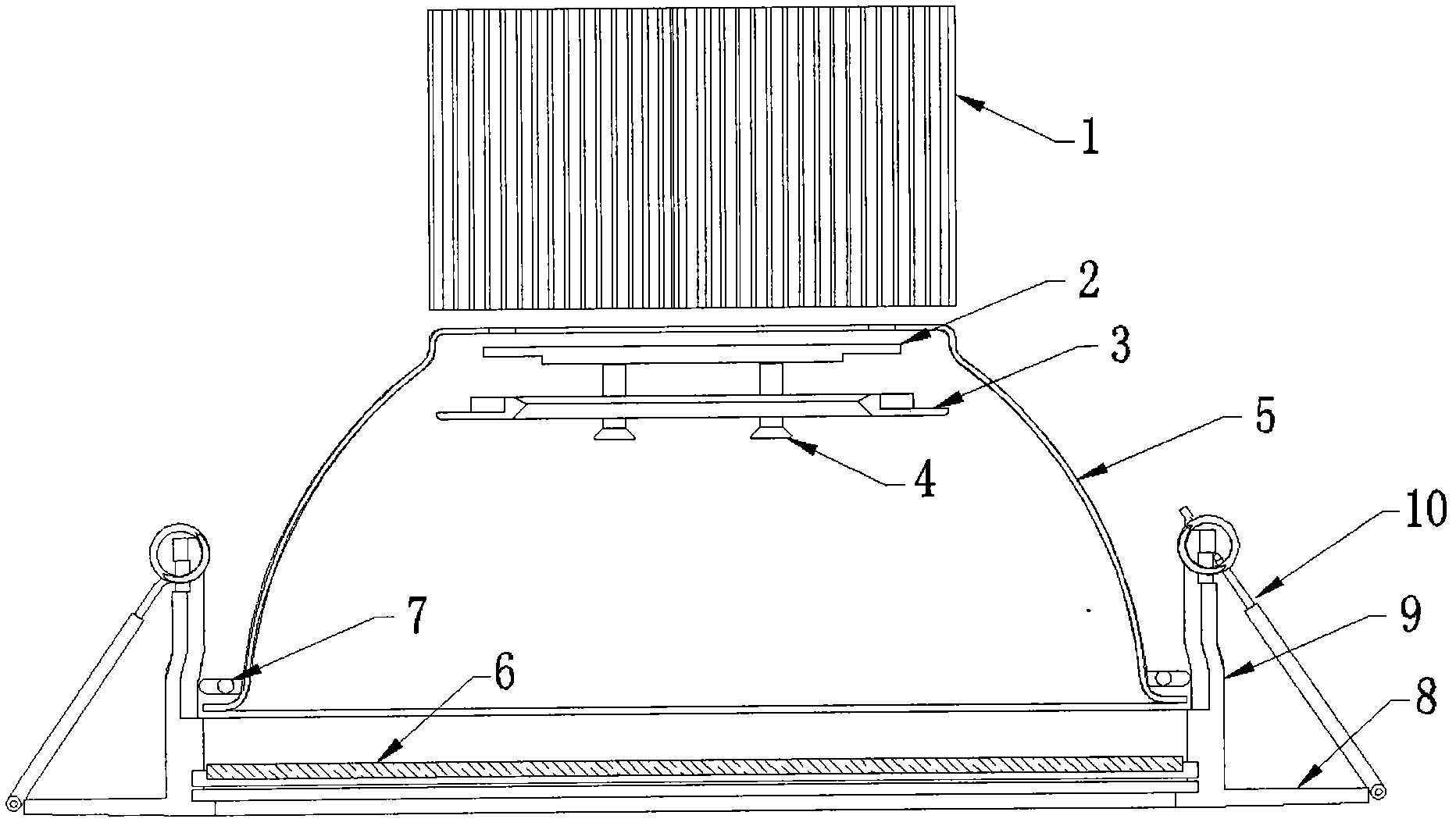

[0028] see figure 1 , a method for designing the structure of a heat dissipation downlight with an LED integrated light source according to the present invention, comprising the following steps:

[0029] 1) Prepare a plastic ring 3, LED integrated light source 2, light reflector 5 and radiator 1, place the plastic ring 3 and LED integrated light source 2 inside the light reflector 5, and place the LED integrated light source 2 in the light reflector 5 Between the flat bottom surface and the plastic ring 3, the radiator 1 is placed on the flat bottom surface outside the light reflector 5;

[0030] 2) Prepare two wires to pass through the light reflector 5 and the heat sink 1 and connect to the LED integrated light source 2;

[0031] 3) The plastic ring 3, the LED integrated light source 2, the light reflector 5 and the heat sink 1 are closely pasted and a screw group 4 is prepared to pass through each component to ensure tighter fixation and good contact with each other.

[0...

Embodiment 2

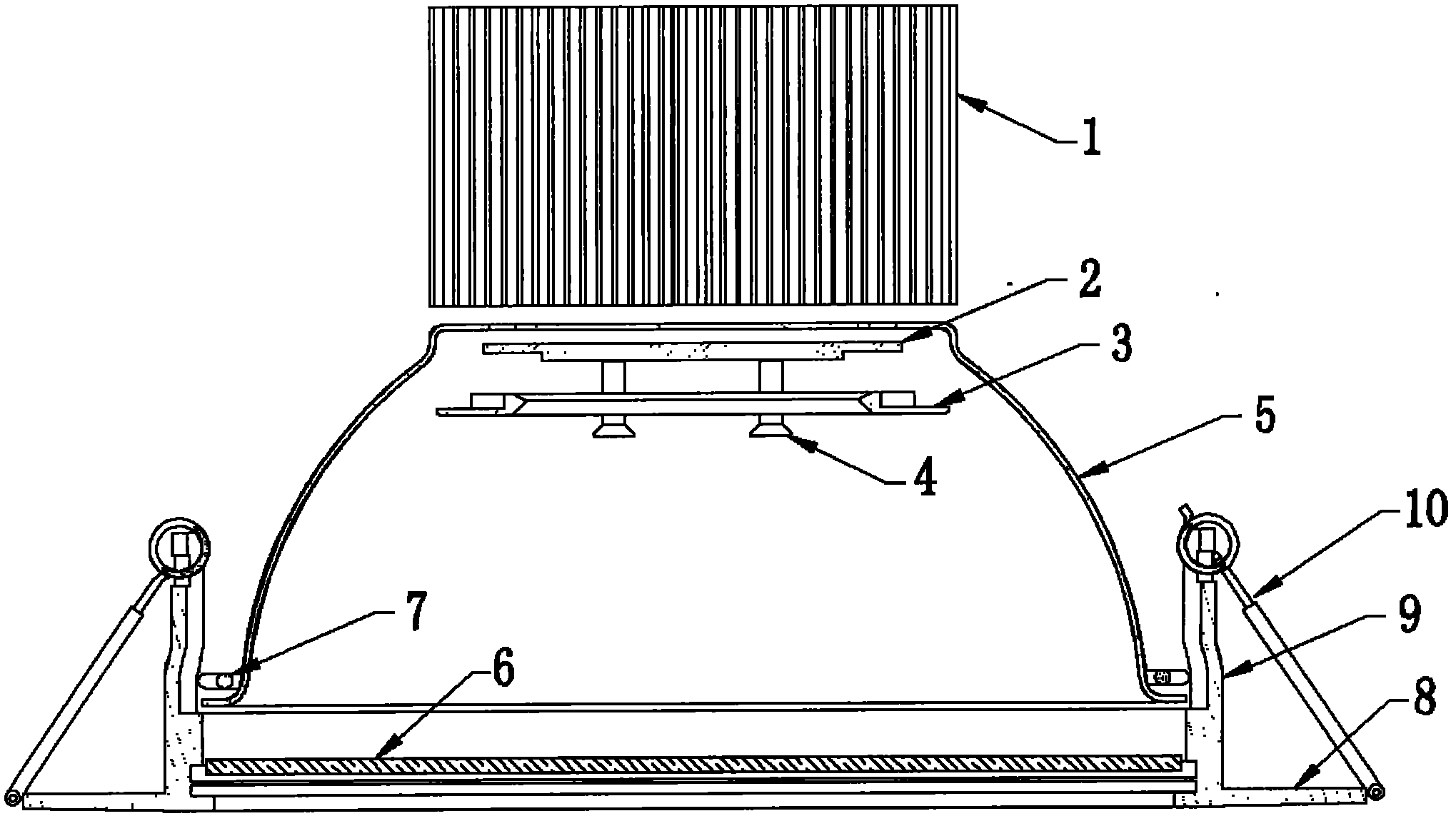

[0045] The difference between this embodiment and Embodiment 1 is that the middle of the flat bottom surface of the light reflector 5 is an empty space, and the back of the LED integrated light source 2 is fully coated with plastic heat-conducting material, placed in a hollowed out place and directly connected to the heat sink 1 paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com