Lamp capable of eliminating light distribution defects of multiple COB light sources and reflecting cup and method thereof

A reflective cup and defect technology, which is applied in optics, light guides, reflectors, etc., can solve the problems of large-scale lens process difficulties, high cost, and lack of light type, and achieve the goal of solving light distribution defects, prolonging service life, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

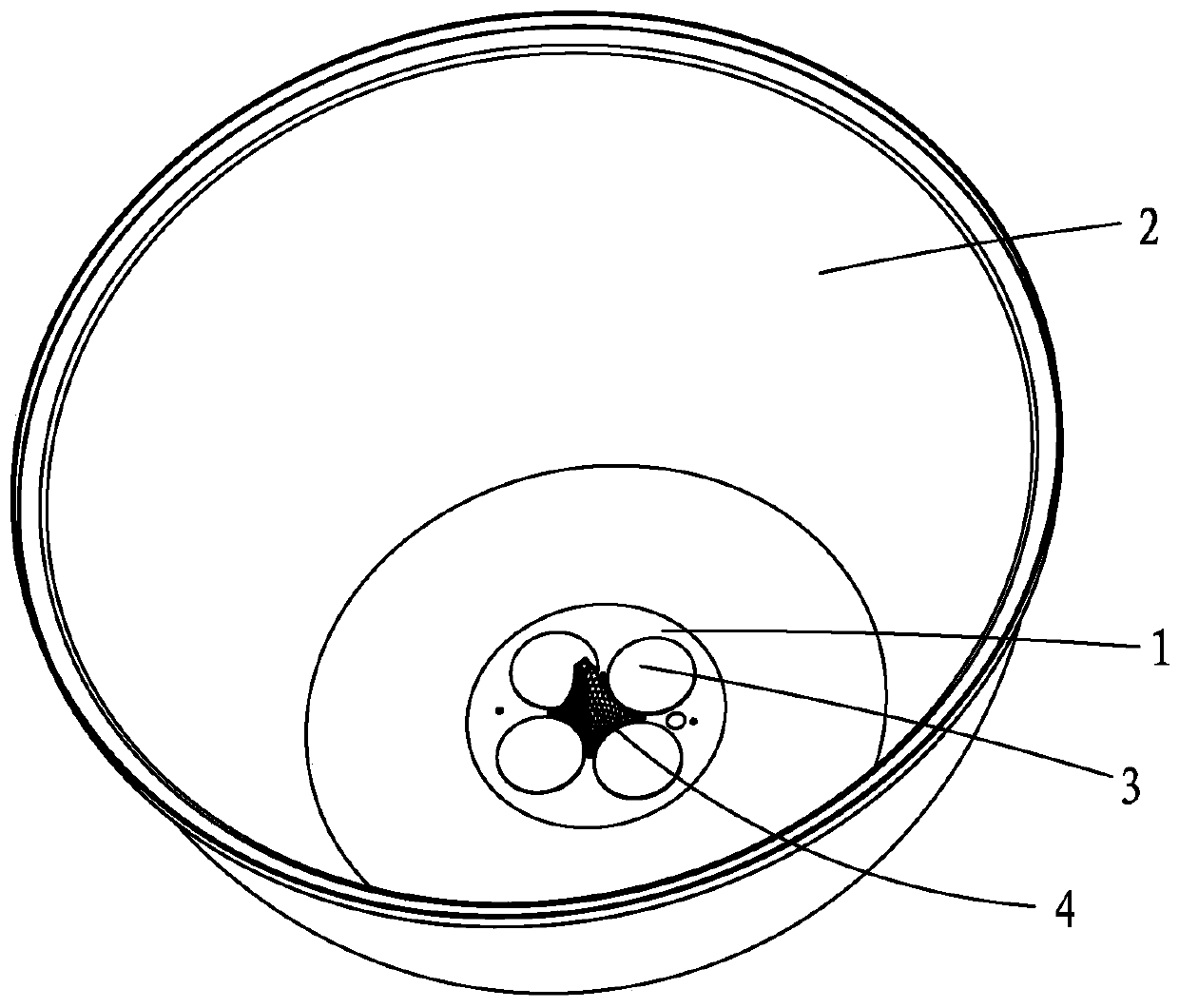

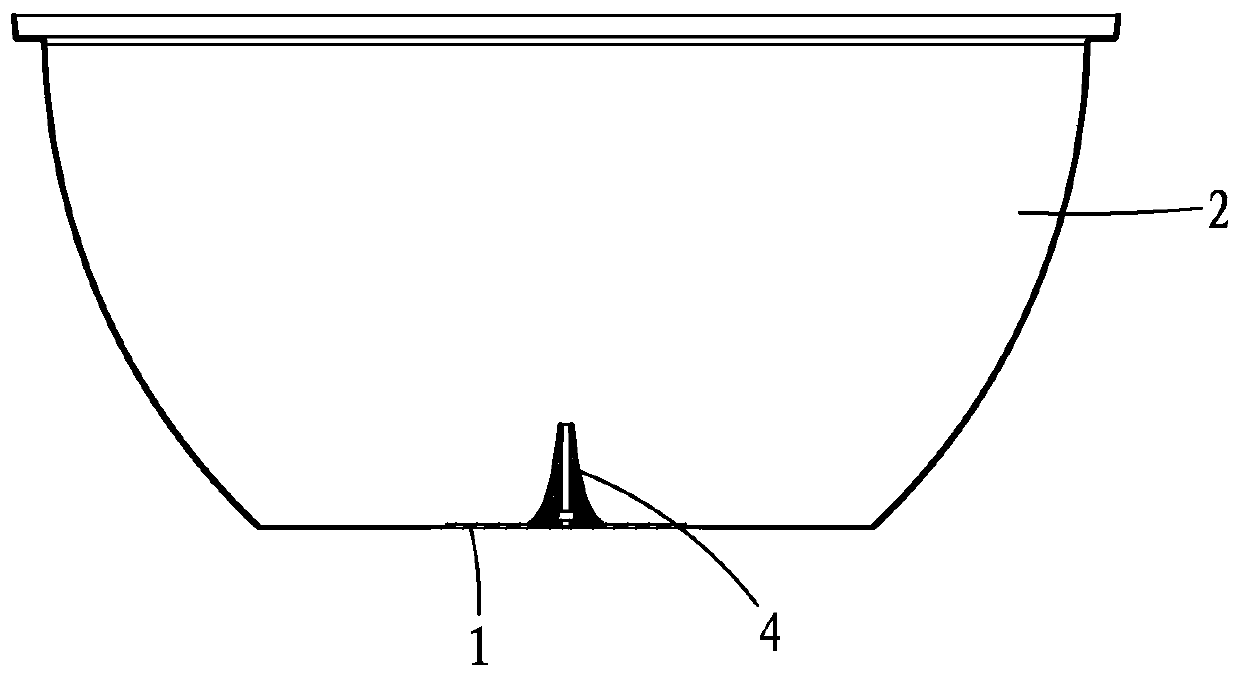

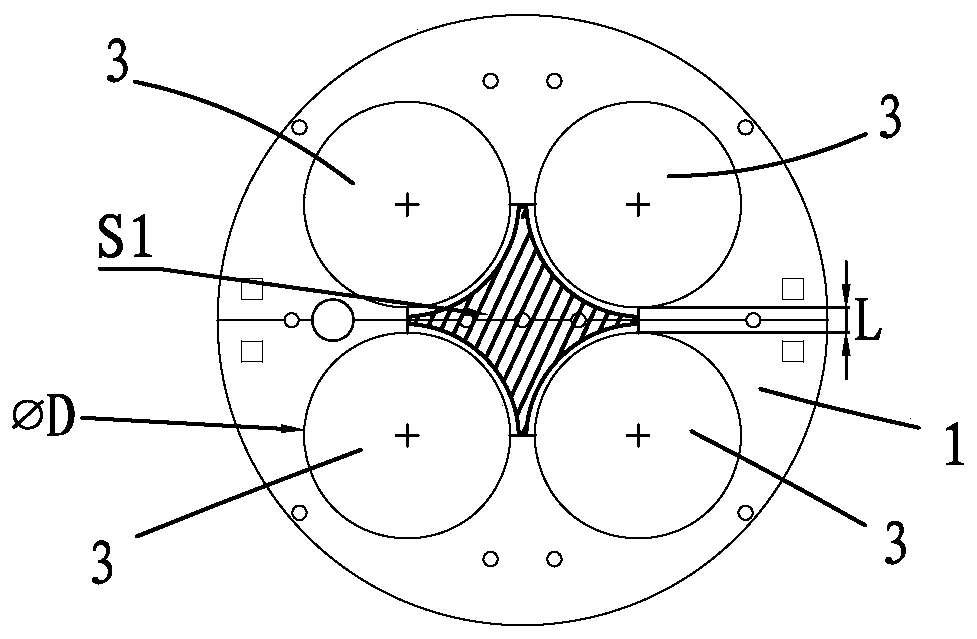

[0063] The embodiment of the present invention solves the technical problem in the prior art that the combination of circular COB illuminants produces light distribution defects in the reflector by providing a lamp and method for eliminating the light distribution defects of multiple COB light sources and reflector cups, and realizes It improves the technical effect of light balance.

[0064] The technical solution in the embodiment of the present invention is to solve the above problems, the general idea is as follows: by adding a light guide between more than three circular COB luminous bodies, the circular COB luminous body and the light guide are both located inside the reflective cup; The bottom surface of the light guide is larger than its top surface, and there is a reflective surface between the bottom surface and the top surface, and the reflective surface corresponds to the circular COB luminous body one by one, and the sum of the areas of the reflective surfaces Gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com