Method for measuring groove center distance of outer groove of bearing

A measurement method, the technology of groove center distance, applied in the direction of mechanical clearance measurement, etc., can solve the problems of increasing production costs of enterprises, expensive detectors, actual groove center distance errors, etc., to improve measurement accuracy, reduce production costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

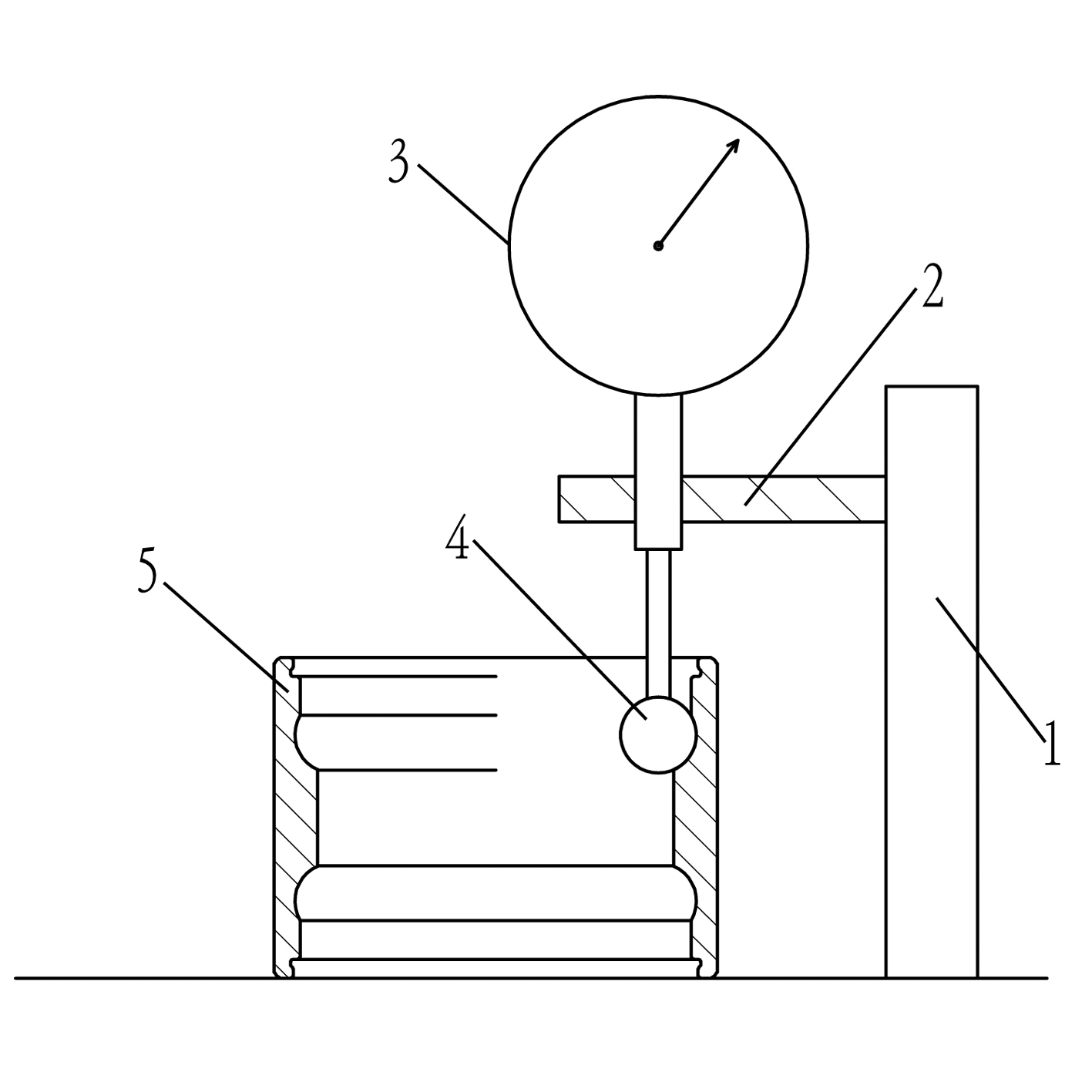

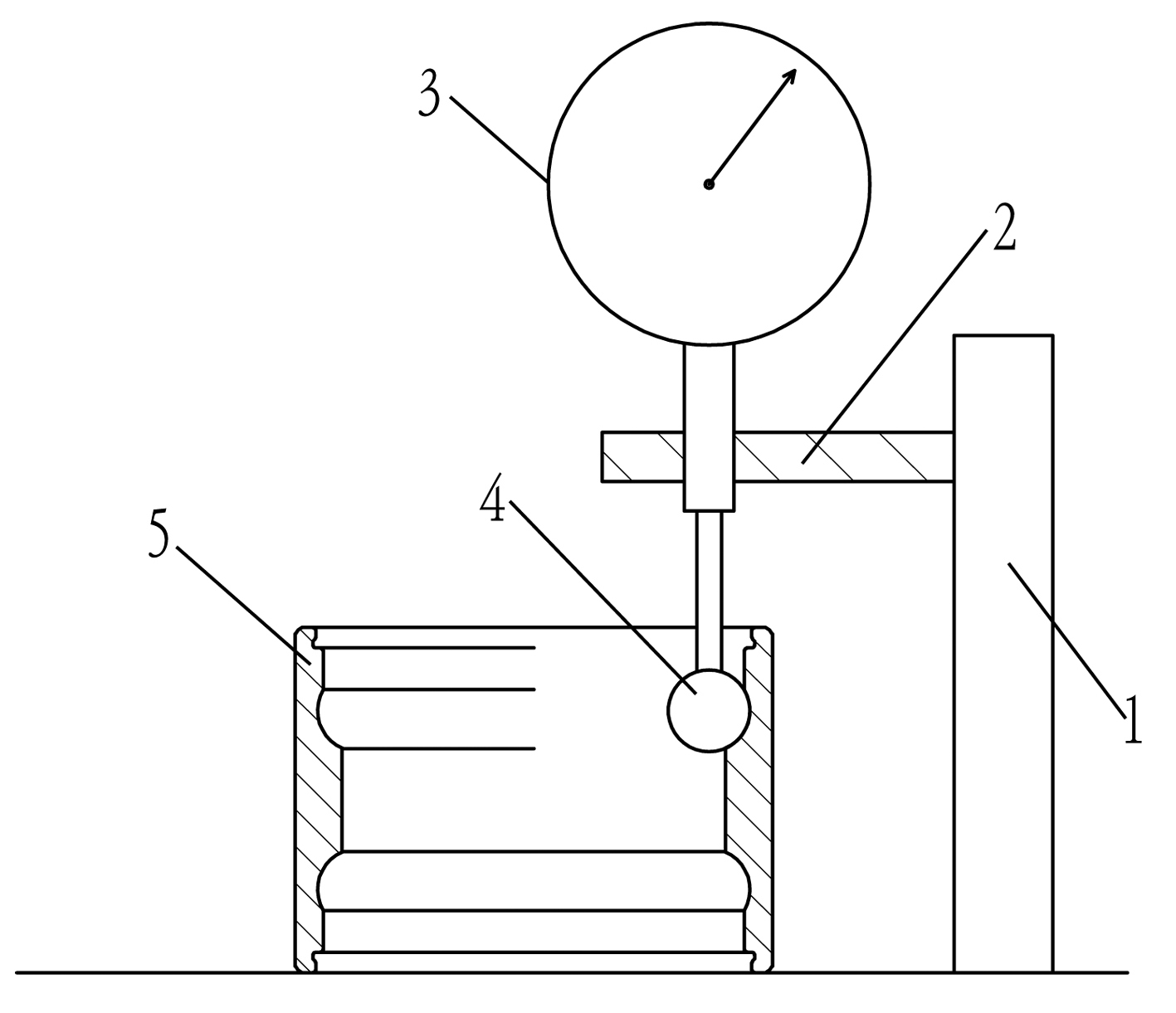

[0016] See attached picture. The measuring device of the present embodiment includes a base as a measuring plane, on which a column 1 is vertically fixed, and the column 1 is provided with a connecting rod 2 parallel to the base, and the connecting rod 2 is provided with a thousand A submeter 3; the measuring end of the micrometer 3 is a measuring ball 4, and the diameter d of the measuring ball 4 is the same as the measured channel radius R.

[0017] Utilizing the above-mentioned measuring device, when measuring in this embodiment, firstly, according to the theoretical value B of the bearing groove center distance 0 and the theoretical value A of the groove-top distance 0 , adjust the distance E=(A 0 +B 0 )-d / 2; then take the tested bearing 5 and place it on the measurement plane, so that the arc of its channel is completely consistent wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com