Grip head for an earth boring unit

A technology of clamping head and ground drilling, which is applied in the direction of drill pipe, drill pipe, earth cube drilling, etc., and can solve problems such as liner insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

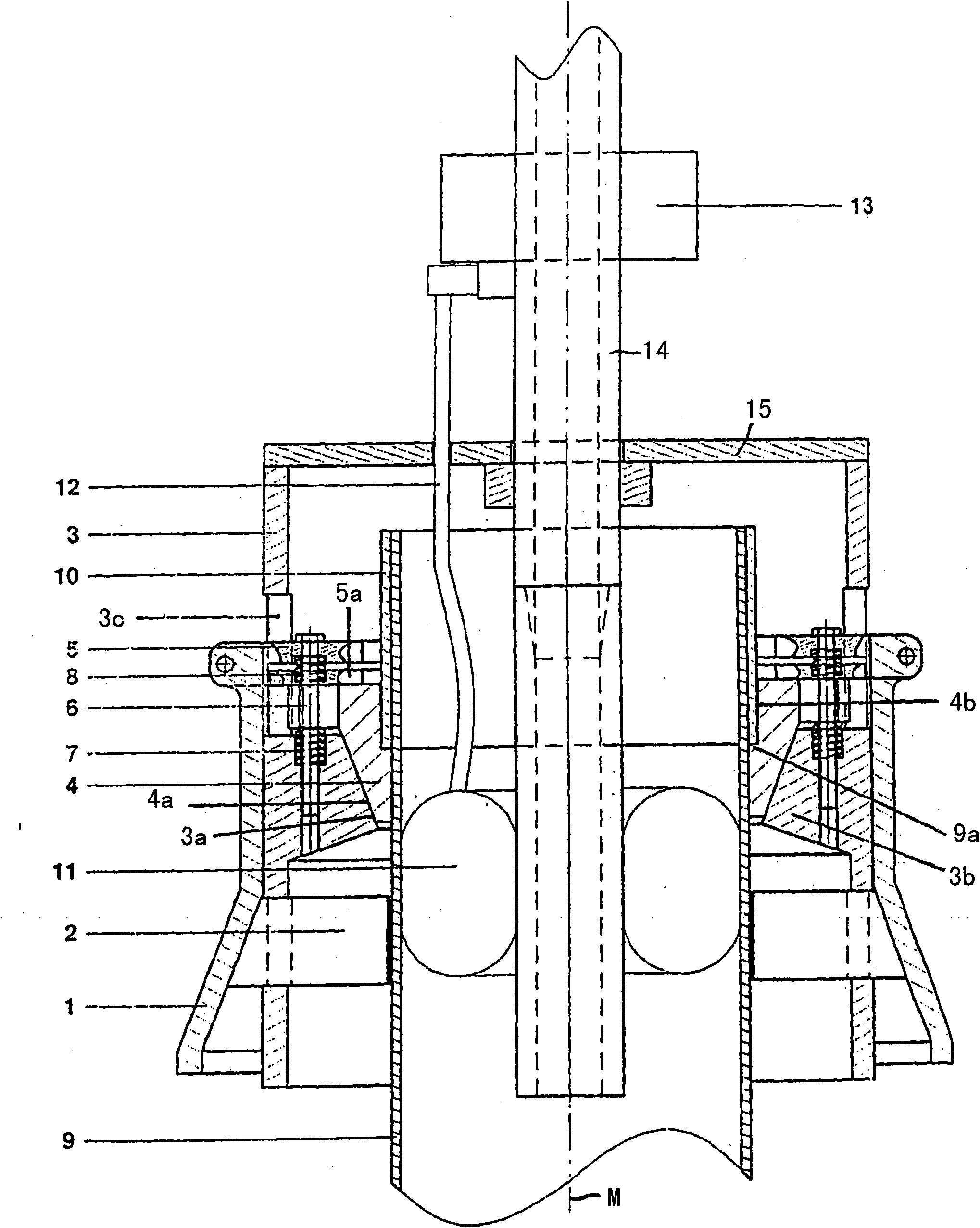

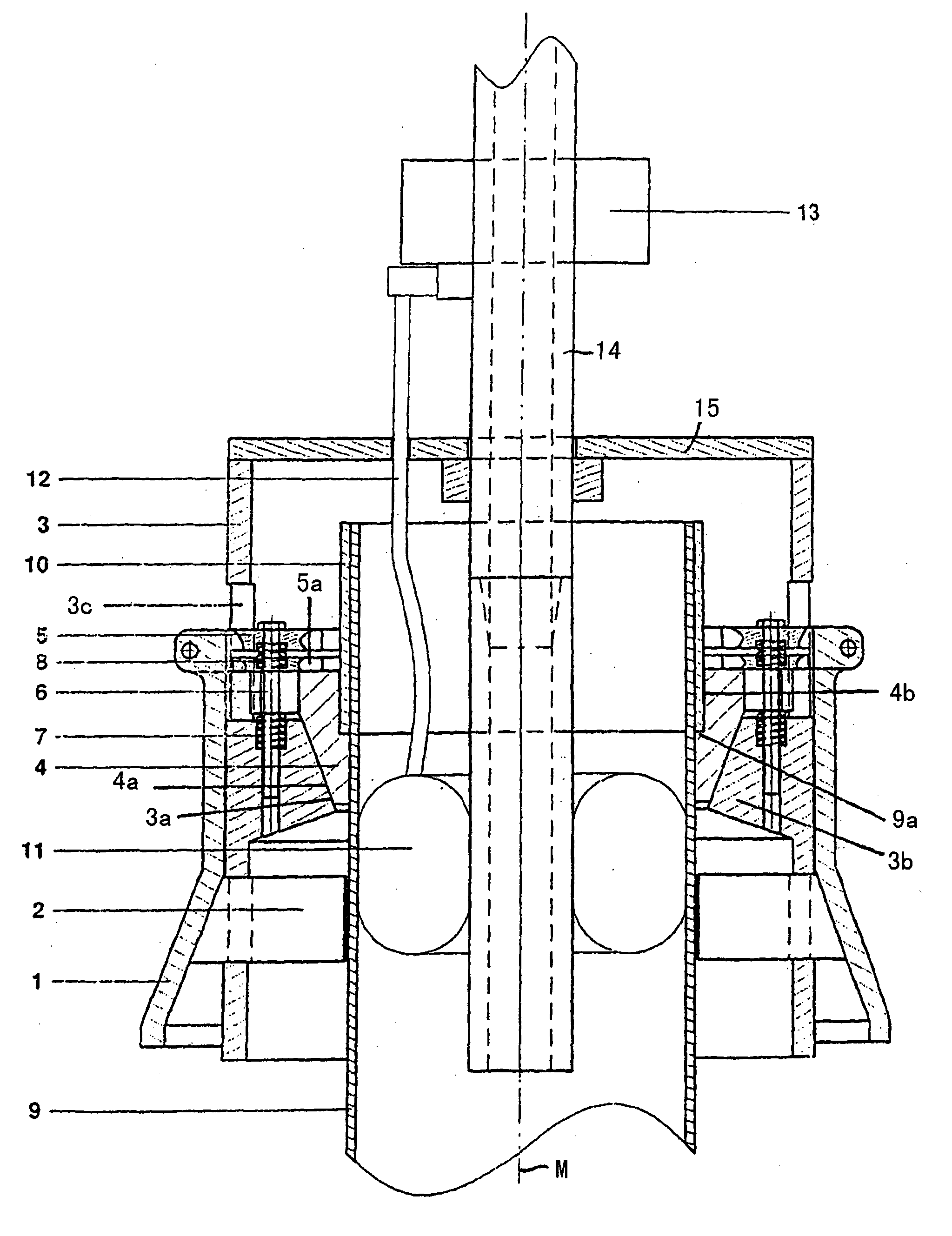

[0024] figure 1 A clamping head according to the invention is shown here in a schematic sectional view, comprising a hollow shaft 3 on which a sleeve 1 is coaxially arranged, which is also called a clamping head cap and its lower funnel Shaped / truncated cone expanding downwards. The funnel-shaped enlarged lower inner wall area of the movable sleeve simultaneously forms an actuating surface for the radially outer ends or inclined surfaces of the individual jaws 2, so that the axial movement of the sleeve downwards causes the individual jaws 2 to automatically Move radially inward. The clamping jaws 2 can then be mounted displaceably on the sleeve 1 and / or on the hollow shaft 3 .

[0025] here in figure 1 Can be seen in the view of a liner 9 inserted in the clamping head according to the invention, wherein the clamping jaws 2 are pressed against the outer surface of the liner 9 from the outside in the radial direction by the downward movement of the outer sleeve 1 and form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com