Design method of high-efficiency desert air filter

An air filter and desert air technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of easy damage of air filter element and easy wear of engine block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

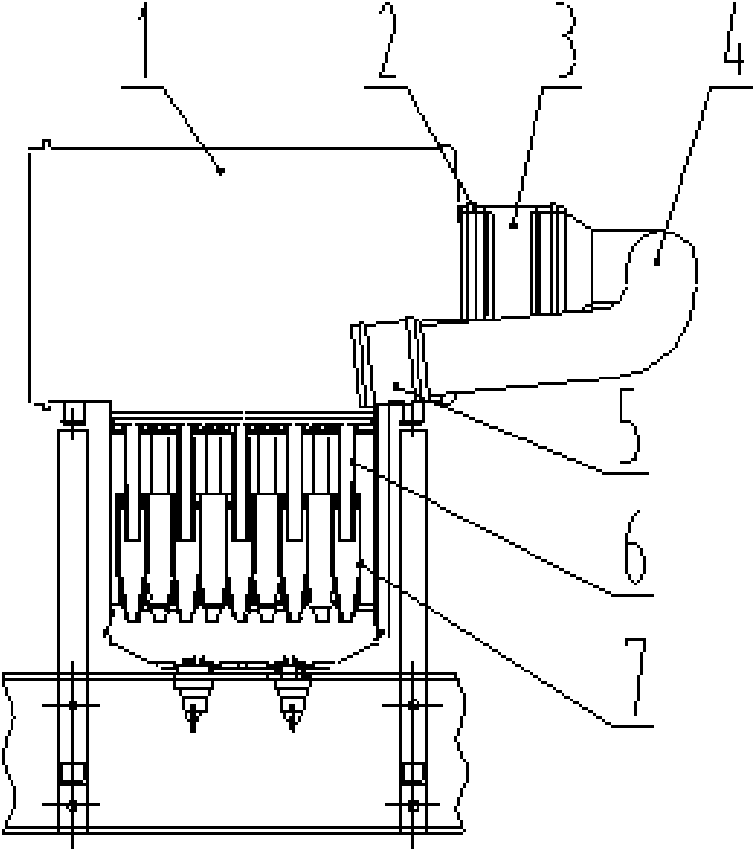

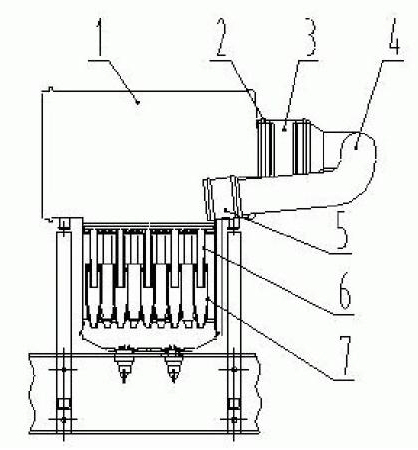

[0013] Example 1 as figure 1 As shown, the design method of this high-efficiency desert air filter is that it adopts a double-chamber air filter mechanism. Its lower chamber performs primary filtration of air, and the upper chamber performs fine filtration of air. Filtering plays an equally important role.

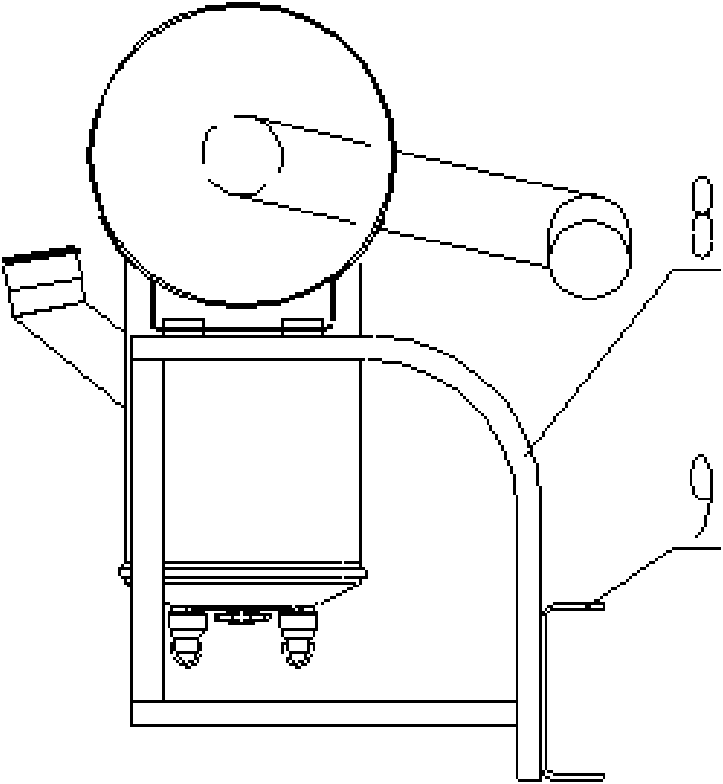

[0014] The high-efficiency desert air filter designed by it mainly includes a chamber air filter mechanism 1, a hoop 2, an inline rubber hose 3, an air intake pipe 4, an outboard rubber hose 5, and a frame support assembly 8. The double-cavity air filter mechanism 1 is sealed and connected with the inner rubber hose 3, the intake pipe 4, and the outer rubber hose 5 in sequence through the hoop 2, and the outer rubber hose 5 is connected with the air inlet of the external engine supercharger ;Such as figure 2 As shown, both ends of the double-cavity air filter mechanism 1 are fixed on the frame support assembly 8, and the frame support assembly 8 is fixed on the girder 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com