Plastic door/window four-head corner cleaning processing device and processing method

A technology for processing equipment and plastic doors and windows, applied in the field of four-end corner cleaning equipment for plastic doors and windows, can solve problems such as low production efficiency of doors and windows, and achieve the effects of improving cleaning speed, accurate positioning and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

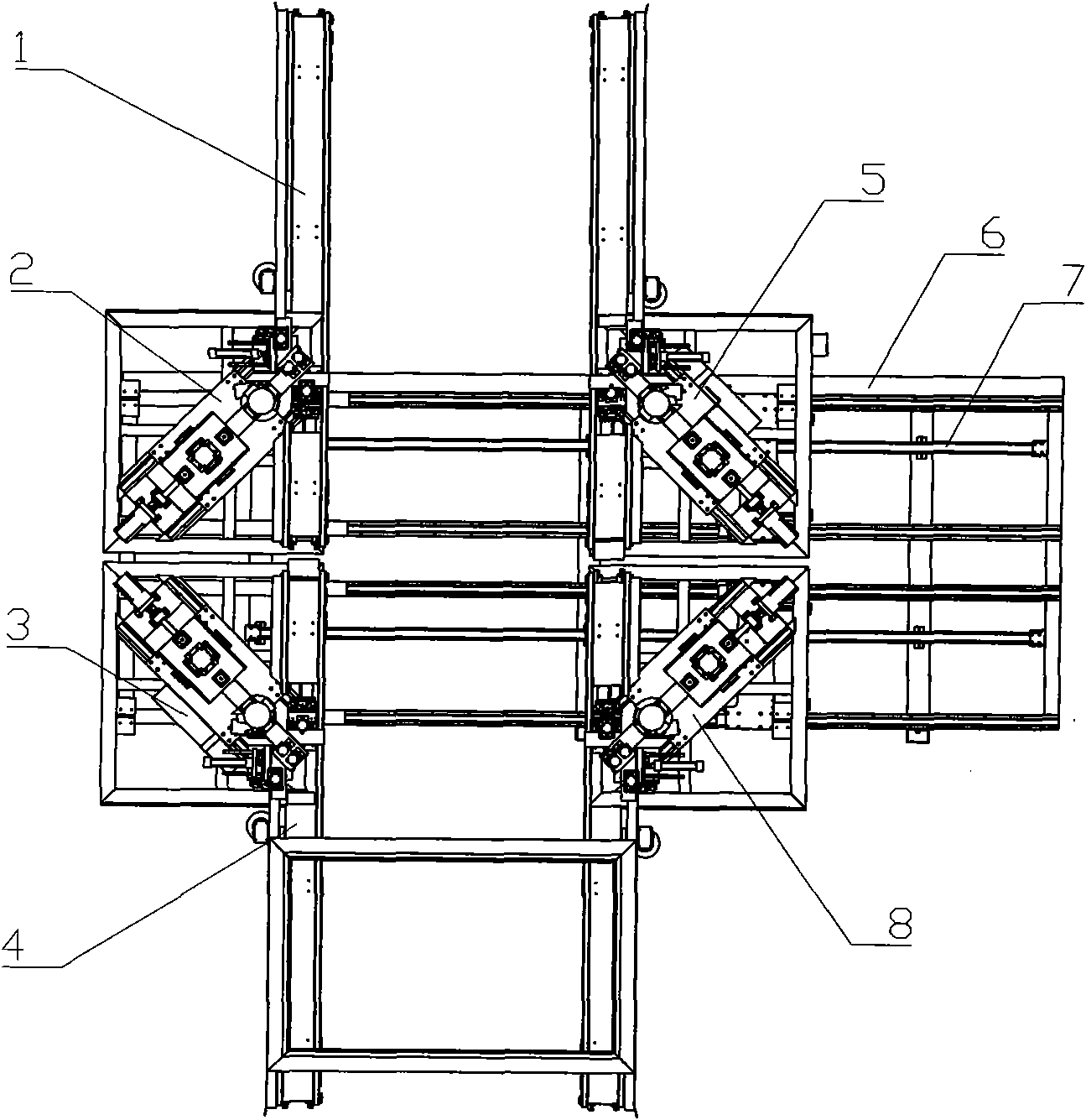

[0032] A four-head angle-clearing processing equipment for plastic doors and windows, such as figure 1As shown, a rectangular frame 6 is provided, and a frame of the frame 6 is horizontally spaced at a certain distance and fixedly connected to the upper left machine head 2 and the lower left machine head 3 arranged back to back, and a parallel guide rail 7 is arranged between the frame and its opposite frame , the spacing of the parallel guide rail 7 is equal to the spacing of the upper left machine head 2 and the lower left machine head 3, and the two tracks of the parallel guide rail 7 are respectively connected with the upper right machine head 5 and the lower right machine head 8 arranged back to back through the slider, and the upper right machine head 5 Connect with the servo motor with the lower right head 8 by the synchronous belt, drive the machine head to move along the parallel guide rail 7 by the servo motor. Between the lower left nose 3 and the lower right nose 8...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap