Base frame for container

A container and chassis technology, applied in the field of containers, can solve the problems of low strength and deformation of the bottom side beams of the container chassis, and achieve the effects of avoiding deformation and increasing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

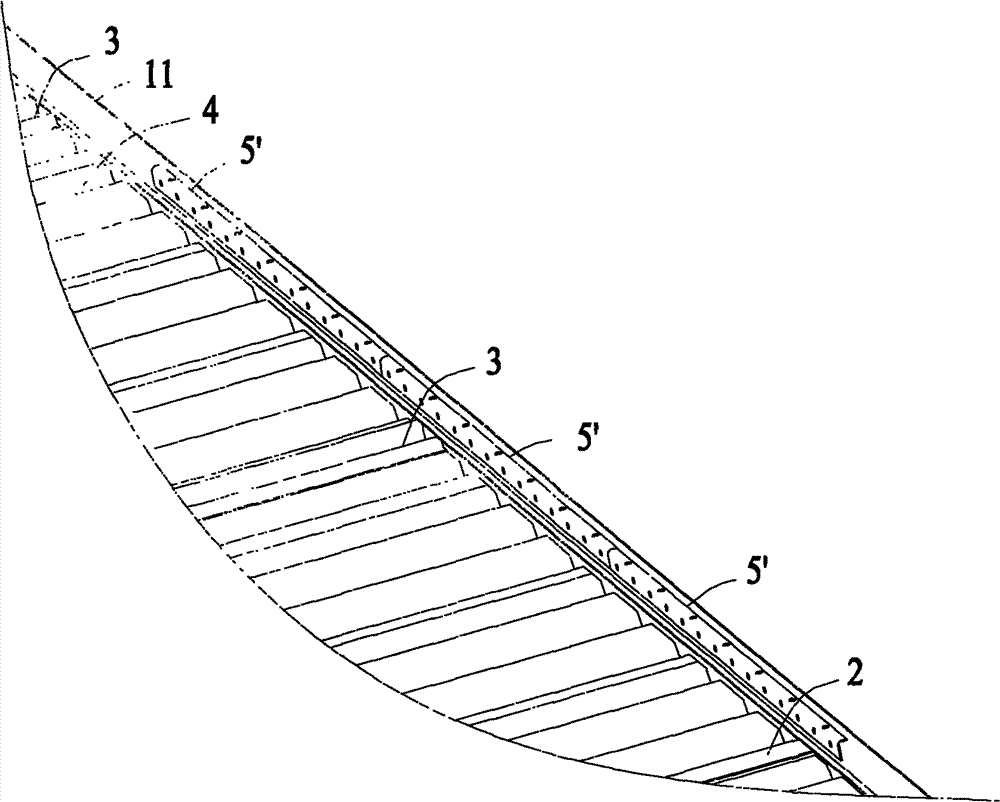

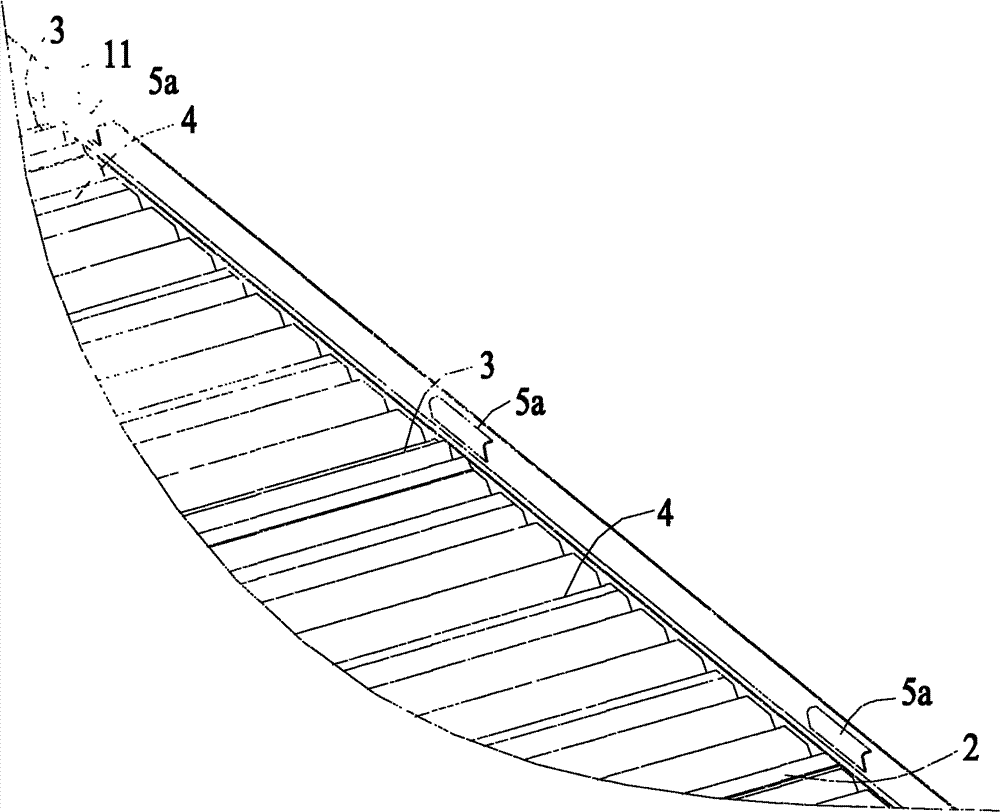

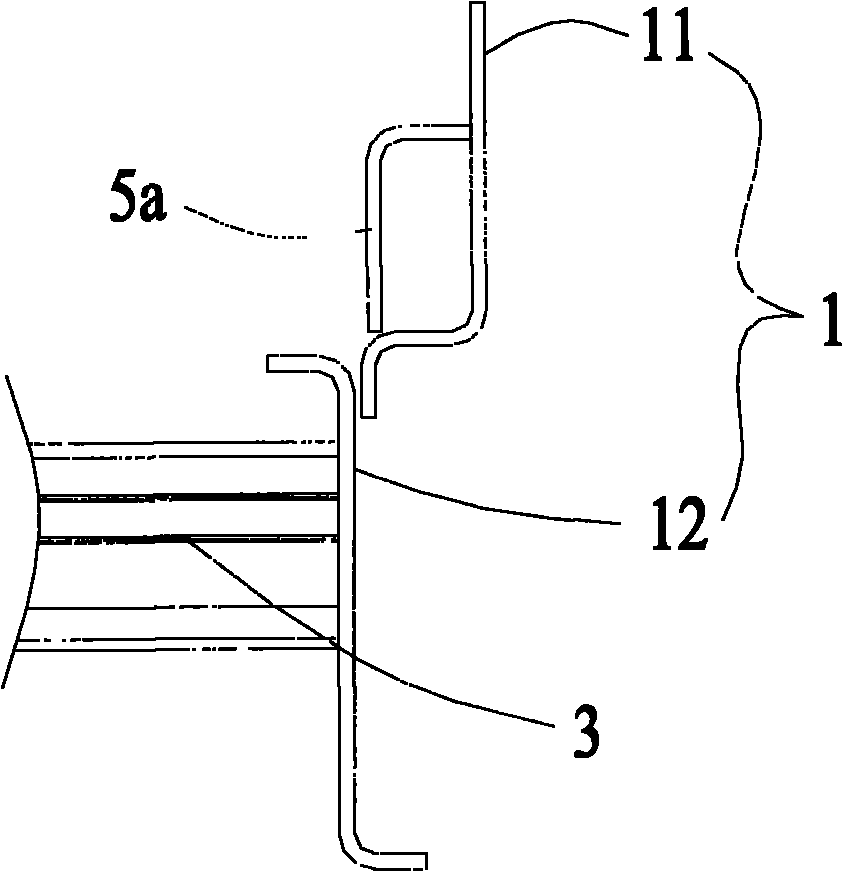

[0026] see figure 2 and image 3 As shown, the cross-section of the reinforced angle steel 5a in this embodiment is inverted L-shaped, the reinforced angle steel 5a is arranged on the inner side of the upper edge 11 of the bottom side beam, and the edge of the reinforced angle steel 5a is connected to the upper edge 11 of the bottom side beam The inner side of the inner surface is vertically connected to form a cavity between the reinforcing angle steel 5a and the upper edge 11 of the bottom side beam. If necessary, the two ends of the reinforced angle steel 5a can also be positioned at the opening of the cavity by welding the sealing plate or directly forming a boxed body (not shown) by bending the two ends of the reinforced angle steel 5a, so as to A closed cavity is formed between the reinforcing angle steel 5a and the upper edge 11 of the bottom side beam.

Embodiment 2

[0028] see Figure 4 As shown, the shape of the outer side of the reinforced angle steel 5b in this embodiment matches the shape of the inner side of the upper edge 11 of the bottom side beam, and the outer sides of each part of the reinforced angle steel 5b are welded closely to the upper edge 11 of the bottom side beam. on the inner side.

Embodiment 3

[0030] see Figure 5 As shown, the shape of the inner side of the reinforced angle steel 5c in this embodiment matches the shape of the outer side of the upper edge 11 of the bottom side beam, and the inner side of each part of the reinforced angle steel 5c is welded closely to the upper edge 11 of the bottom side beam. on the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com