Ganoderma sinense mycelium polysaccharide refined substance as well as preparation method and use thereof

A technology of mycelium polysaccharides and Zizhi, which is applied in the direction of drug combinations, pharmaceutical formulas, medical preparations containing active ingredients, etc., can solve problems that do not involve polysaccharide molecules, polysaccharides, monosaccharides, etc., and achieve obvious anti-tumor activity and dosage The effect of small, high polysaccharide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

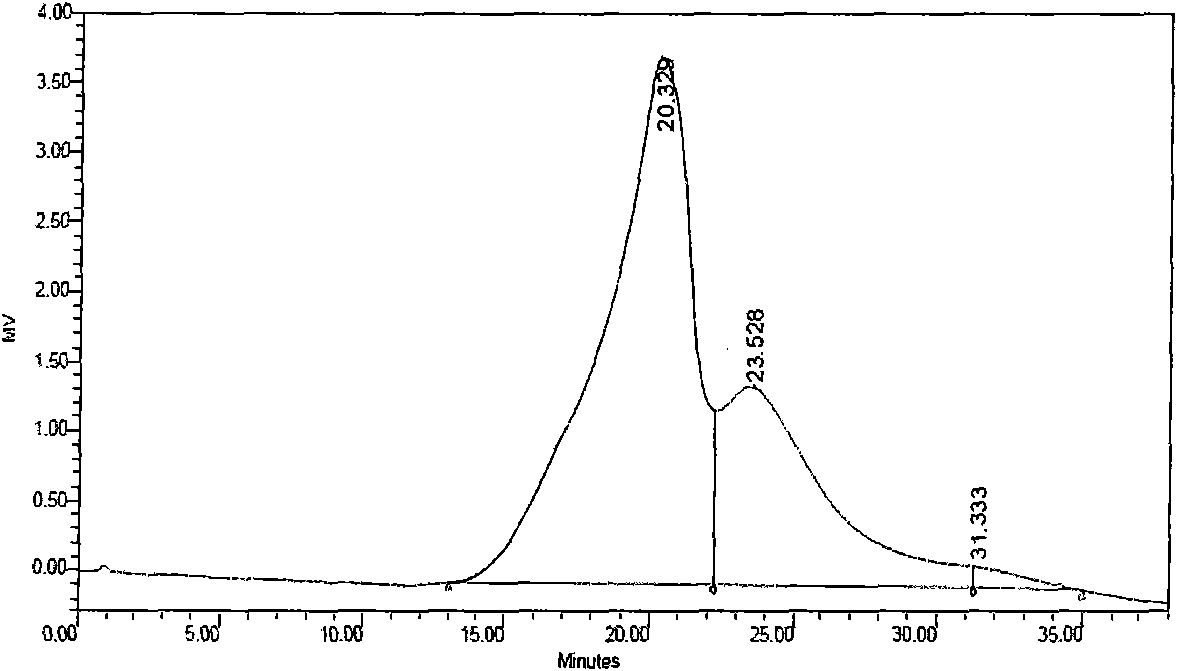

Image

Examples

Embodiment 1

[0060] Crude polysaccharide extraction:

[0061] Ganoderma sinense was used for liquid fermentation to obtain 1300 L of fermentation broth, the obtained mycelium was washed with water, and plate-and-frame filter press was performed. The mycelium was extracted twice with 3 times of water and heated for 3 hours each time, and the extraction temperature was 90°C. The water extracts were combined and concentrated until the ratio of the amount of mycelium to the amount of medicinal solution was 1:2, and then 4 times of 95% alcohol was added to precipitate overnight, and the precipitate was taken out and dried to obtain 119.22 g of crude polysaccharide.

[0062] The polysaccharide content of the crude polysaccharide measured by the phenol sulfuric acid method was 34.9%.

[0063] Crude polysaccharide refining:

[0064] Take the above crude polysaccharide and dissolve it in 20 times of water, separate the crude polysaccharide solution with an ultrafiltration membrane with a molecula...

Embodiment 2

[0068] Crude polysaccharide extraction:

[0069] Ganoderma sinense was used for liquid fermentation to obtain 1300 L of fermentation broth, the obtained mycelium was washed with water, and plate-and-frame filter press was performed. The mycelium was extracted with 3 times of water and heated for 3 times, each time for 2 hours, and the extraction temperature was 80°C. The water extracts were combined and concentrated until the ratio of the amount of mycelium to the amount of medicinal solution was 2:1, and then added 3 times of 85% alcohol to precipitate overnight, and the precipitate was taken out and dried to obtain 144.46 g of crude polysaccharide.

[0070] The polysaccharide content of the crude polysaccharide measured by the phenol sulfuric acid method was 42.8%.

[0071] Crude polysaccharide refining:

[0072] Take the above crude polysaccharide and dissolve it in 20 times of water, separate the crude polysaccharide solution with an ultrafiltration membrane with a molec...

Embodiment 3

[0076] Crude polysaccharide extraction:

[0077] Ganoderma sinense was used for liquid fermentation to obtain 1300 L of fermentation broth, the obtained mycelium was washed with water, and plate-and-frame filter press was performed. The mycelium was extracted with 3 times of water and heated for 3 times, each time for 2 hours, and the extraction temperature was 80°C. The water extracts were combined and concentrated until the ratio of the amount of mycelium to the amount of medicinal solution was 2:1, and then added 3 times of 85% alcohol to precipitate overnight, and the precipitate was taken out and dried to obtain 144.46 g of crude polysaccharide.

[0078] The polysaccharide content of the crude polysaccharide measured by the phenol sulfuric acid method was 42%.

[0079] Crude polysaccharide refining:

[0080] The above crude polysaccharide was dissolved in 20 times of water, the crude polysaccharide liquid was separated by an ultrafiltration membrane with a molecular wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com