Drying machine and washing and drying machine

A technology for dryers and clothes, which is applied to washing devices, household clothes dryers, and washing machines with containers, etc., which can solve the problem of reducing uneven drying of clothes, inability to determine uneven drying, and inability to switch drying Use air and other problems to achieve the effect of reducing uneven drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

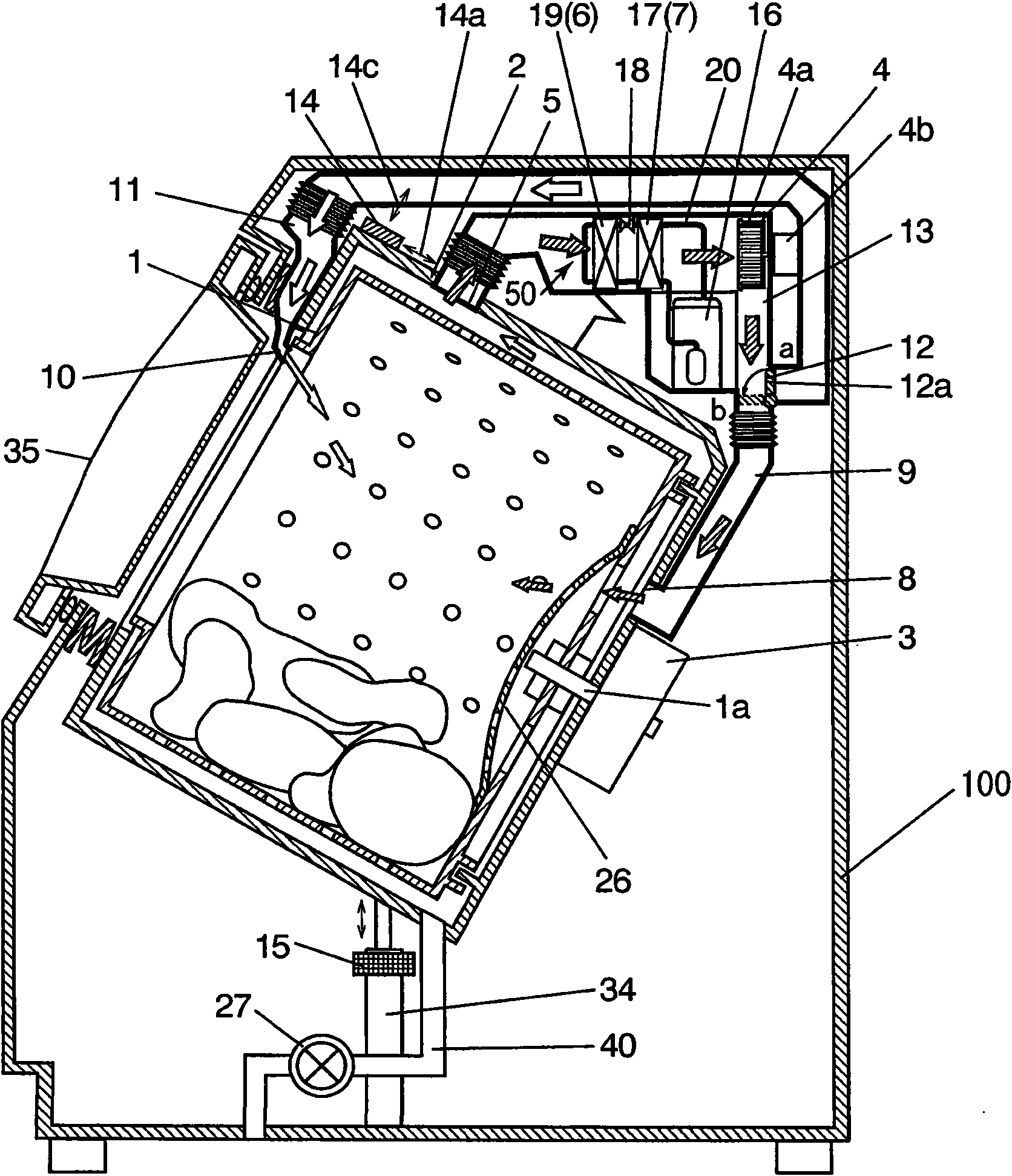

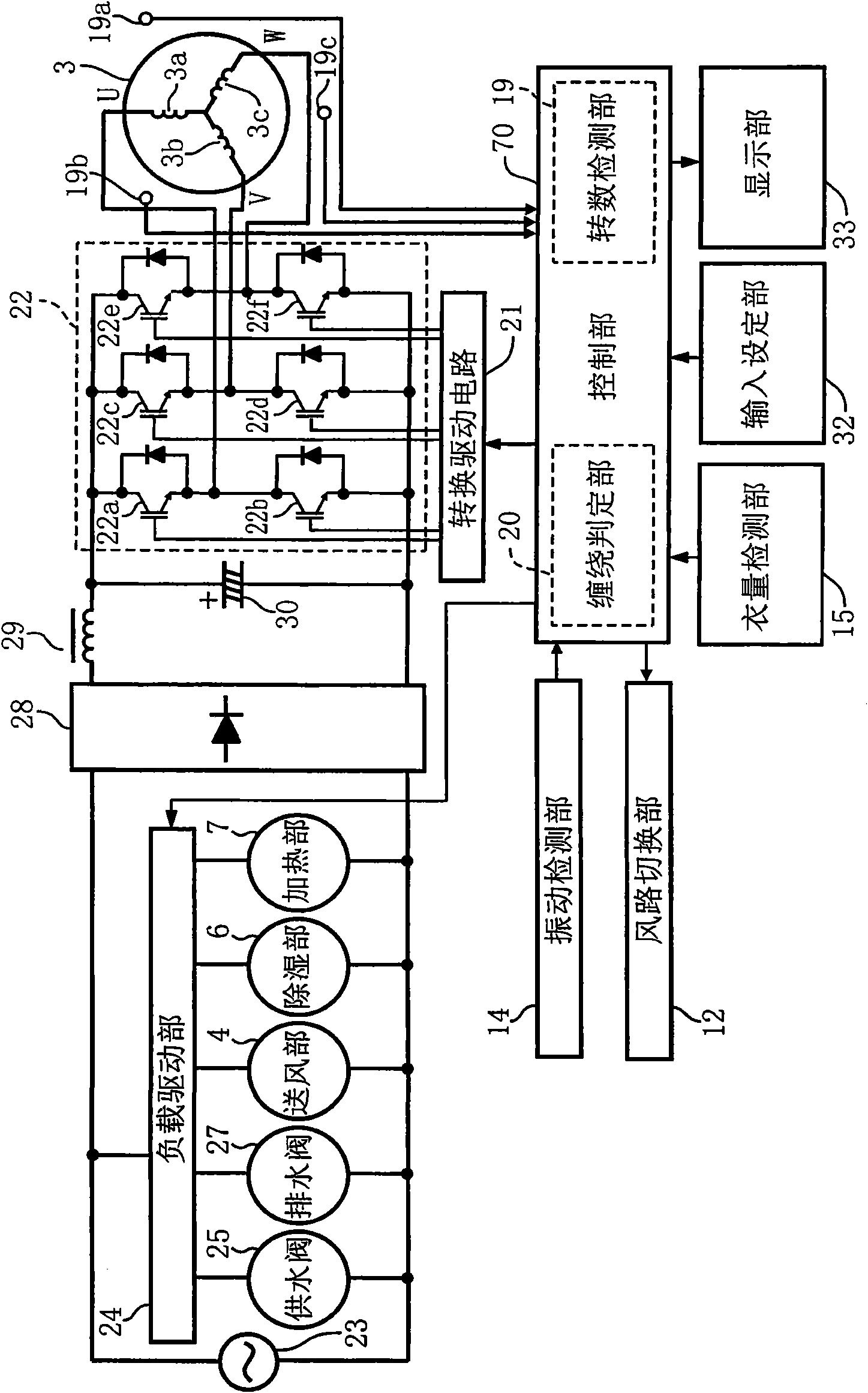

[0120] Hereinafter, Embodiment 2 of the present invention will be described in detail with reference to the drawings.

[0121] The basic structure and the figure 1 , figure 2 , Figure 9 The drum-type washing and drying machines according to Embodiment 1 shown in the above description are the same, so the same part numbers are attached to the same configurations, and descriptions thereof are appropriately omitted.

[0122]The operation and effects of the drum-type washing and drying machine will be described in detail below focusing on differences from the drum-type washing and drying machine according to Embodiment 1. FIG.

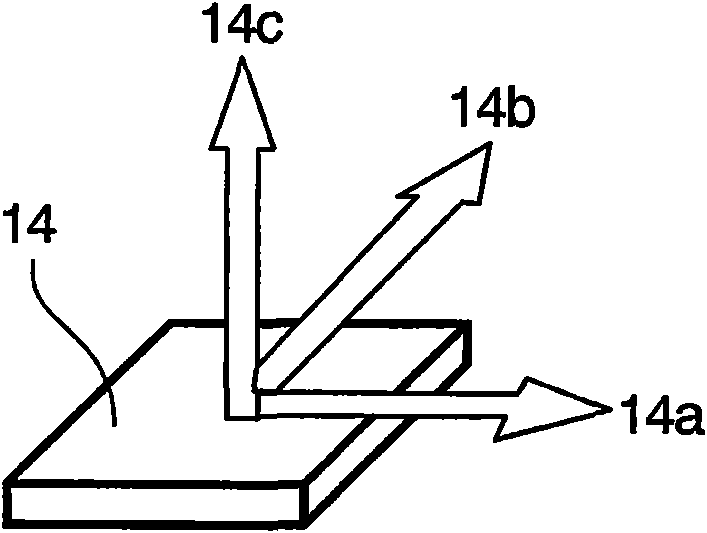

[0123] In this embodiment, Figure 11 The shown control unit 170 accurately determines the degree of drying of the clothes in the drum 1 (the clothes on the outlet side are fully dried) based on the vibration value detected by the vibration detection unit 14 fixed to the support tub 2 . The principle is described below.

[0124] In the drying proces...

Embodiment approach 3

[0144] In Embodiment 2 above, the air volume or wind speed when selecting the first air passage 9 or the second air passage 11 is not particularly limited. For example, when selecting any air path, the same air volume and the same wind speed can be used. In contrast, in this embodiment, when the first air passage 9 is selected, the drying air with a larger air volume is blown from the first outlet 8 into the drum 1 than when the second air passage 11 is selected. When the second air path 11 is selected, the drying air of high pressure and high speed is blown from the second air outlet 10 into the drum 1 compared with the first air path 9, which can not only reduce power consumption but also reduce uneven drying , and can also reduce wrinkles of clothes based on high-pressure and high-speed drying air.

[0145] The basic structure and the figure 1 , Figure 9 , Figure 11 The drum-type washing and drying machines according to the first and second embodiments described above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com