Square shaft structure of rotary drilling rig

A technology of rotary drilling rig and square shaft, which is applied in the direction of drilling equipment, earthwork drilling and production, supporting devices, etc. It can solve the problems of being gradually torn and the drilling rig cannot continue to work, etc., and achieve the effect of reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

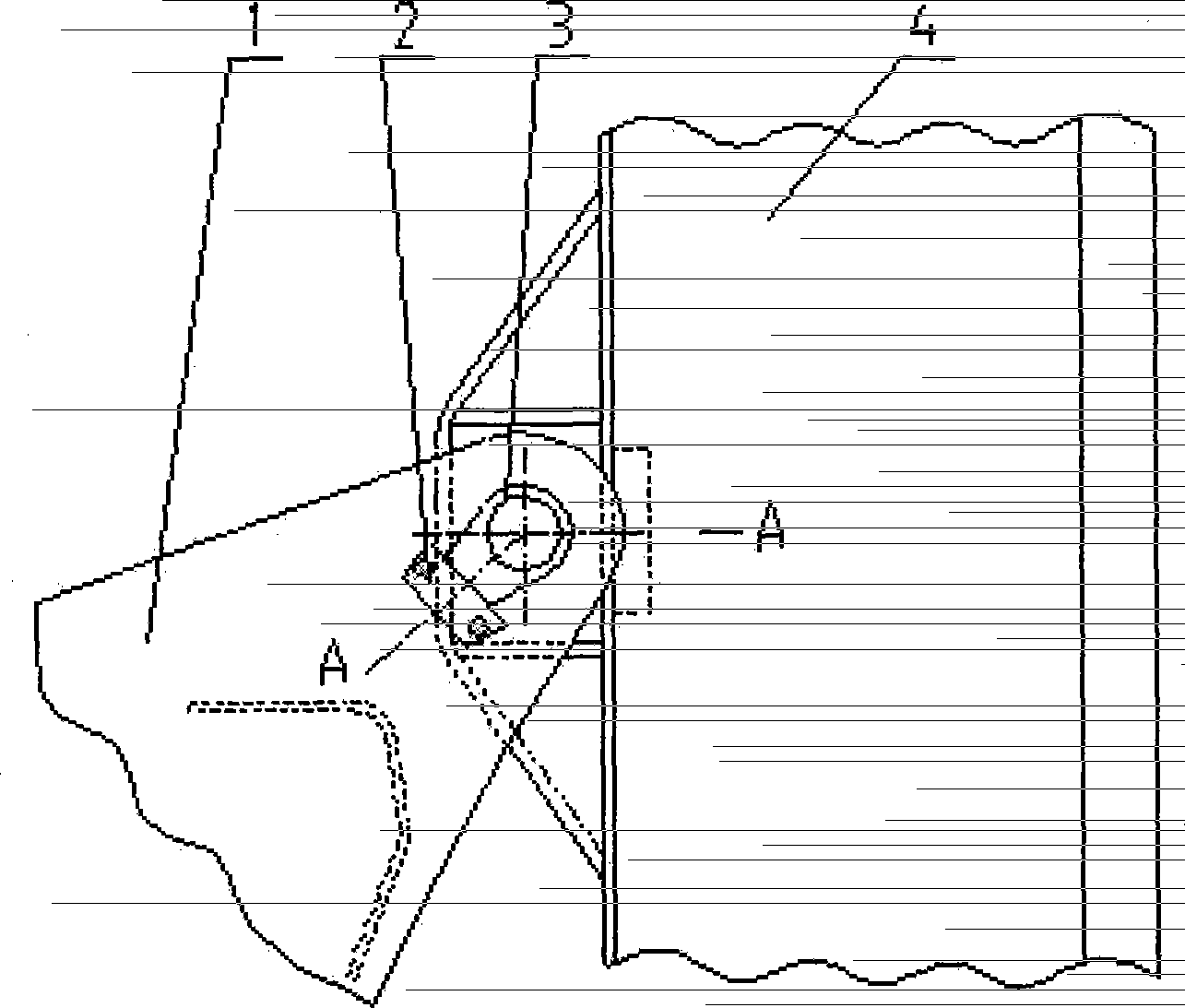

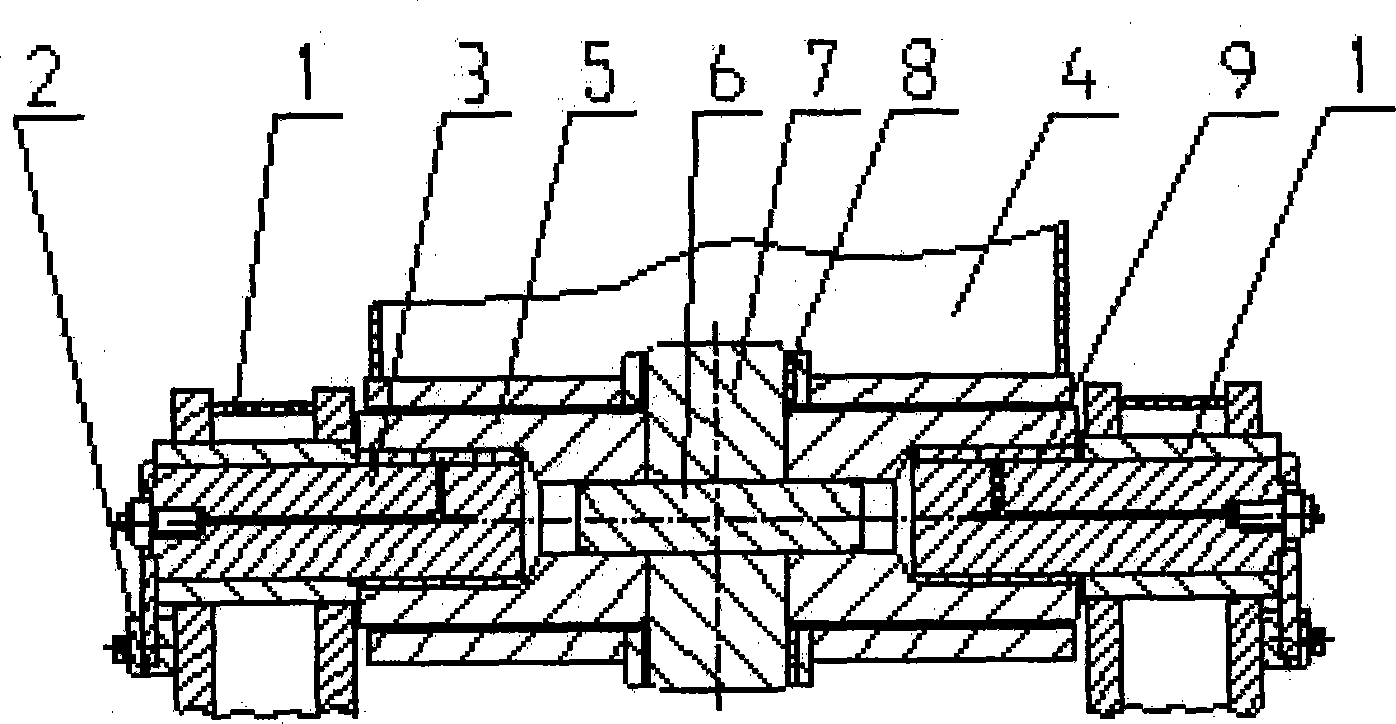

[0012] Connect the tripod 1 with the boom and pull rod of the rotary drilling rig through the pin shaft; put the bushing I8 into the hole with the stop from the inner side of the drill mast 4 square box, and put the bushing II9 into it first In the holes at both ends of the square shaft 5, put it into the square box of the drill mast 4 together with the square shaft 5, and keep the through hole of the square shaft 5 concentric with the bushing I8, and then load the main shaft 7 and the positioning pin shaft 6 in sequence; Put the drill mast 4 that has completed the above assembly process into the inner crotch of the tripod 1, while keeping the installation hole of the tripod 1 basically concentric with the bushing II9, install the pin assembly 3 from both sides of the tripod 1 respectively, and Use the pressure plate assembly 2 to secure it.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap