Blade-collapsible, oil resistance-regulated and controlled vertical-spindle wind-driven generating device

A wind power generation device, vertical axis technology, applied in the direction of wind engine, wind engine, wind motor combination, etc. at right angles to the wind direction, can solve the difficulty of further improving the utilization efficiency of wind energy, electrical machinery, machine damage, and unsatisfactory results problems, to achieve the effect of improving wind energy utilization efficiency, reducing secondary damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] For better understanding and implementation, the vertical axis wind power generation device with foldable blades and oil resistance speed regulation and control of the present invention will be described in detail below with reference to the accompanying drawings.

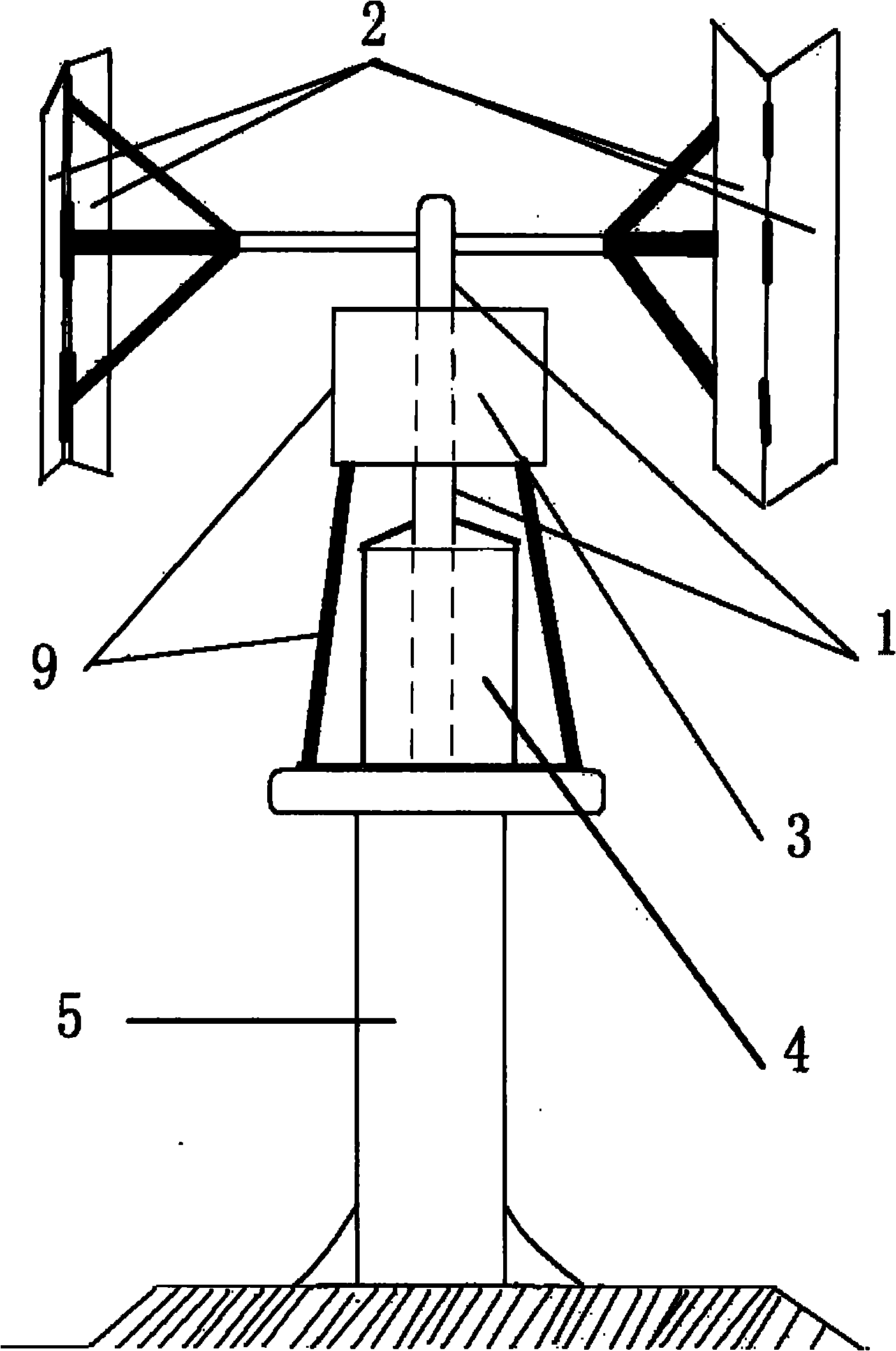

[0036] Please refer to the attached figure 1 Shown is a structural schematic diagram of a vertical axis wind power generation device with foldable blades, oil resistance speed regulation and control.

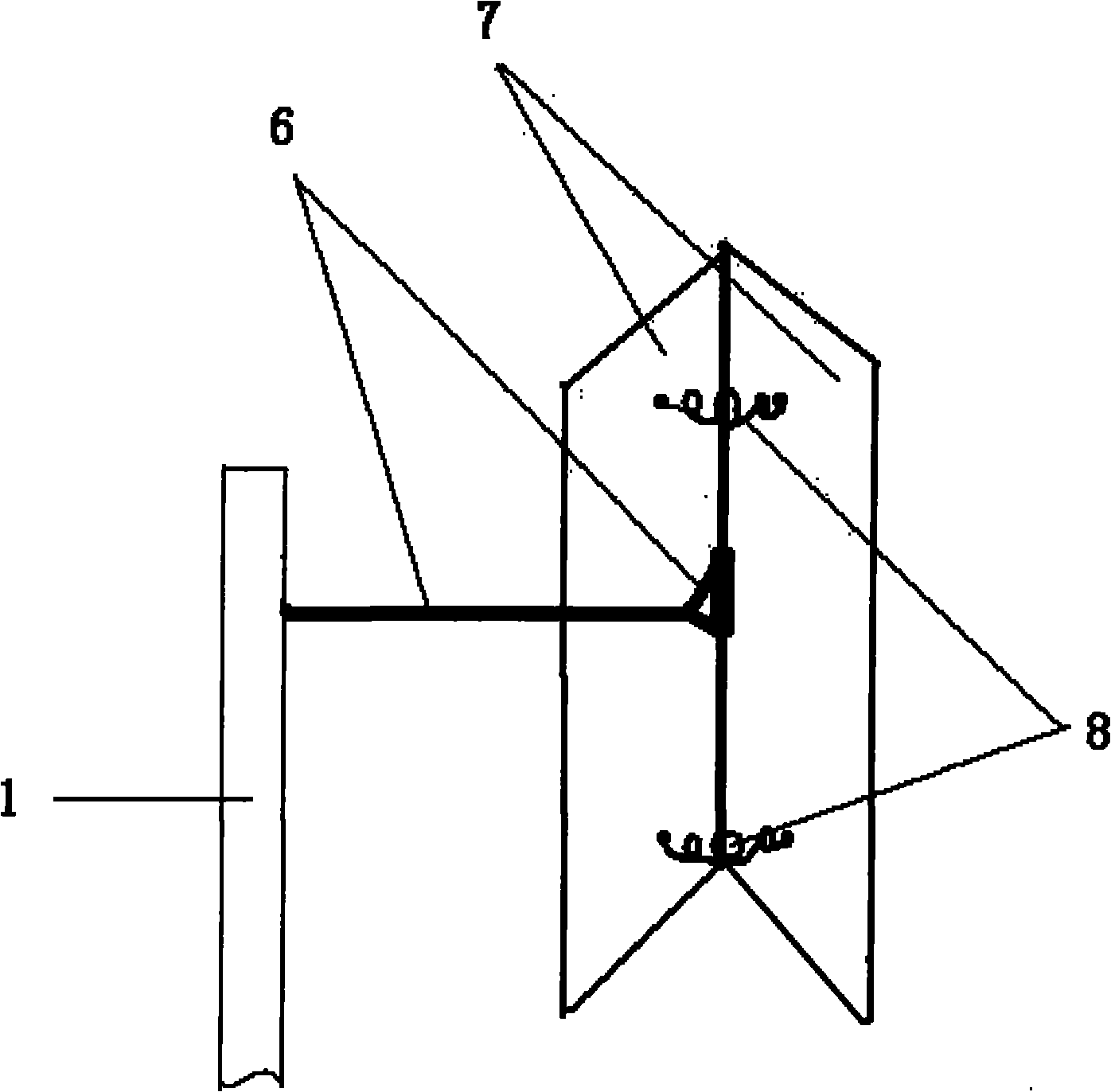

[0037] Please refer to the attached figure 2 Shown is a schematic diagram of the structure of the blade part in the vertical axis wind power generation device with foldable blades, oil resistance and speed regulation control. The foldable blade 2 of the blade part is installed on the shaft 1 and the bracket 6. Blades 7 and springs 8, the larger the windward angle of the system, the greater the stress area, and the smaller the leeward angle, the smaller the force area, thereby improving the efficiency of wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com