Axial adjustable diaphragm coupler

A diaphragm coupling and axial technology, which is applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of affecting the smooth operation of the coupling and the high processing cost of the spline shaft sleeve connection, and achieves Improve axial installation accuracy, improve safety, and have good structural effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

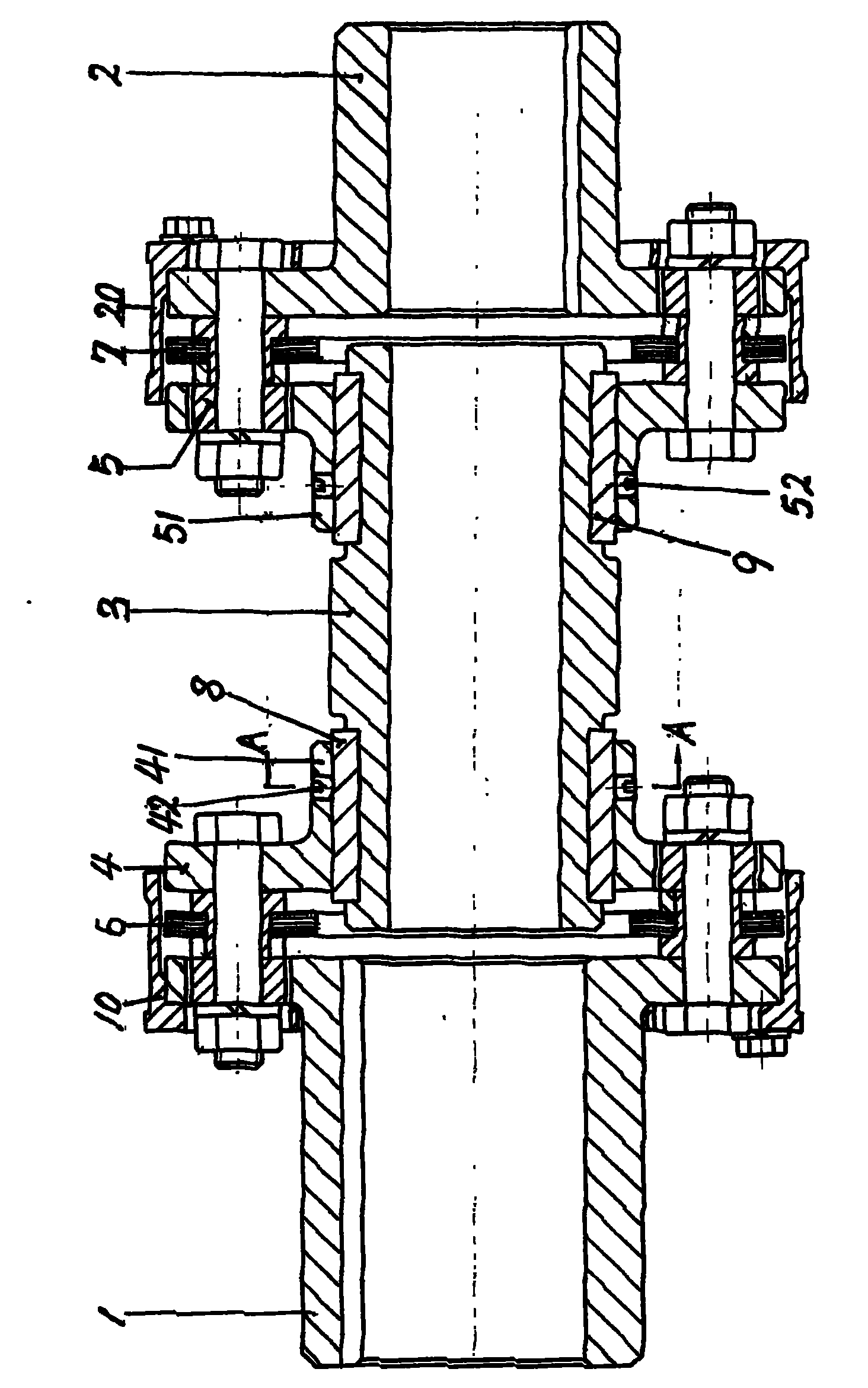

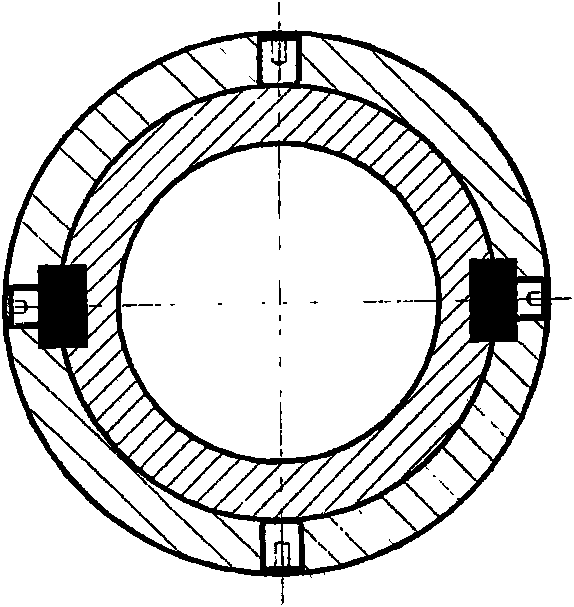

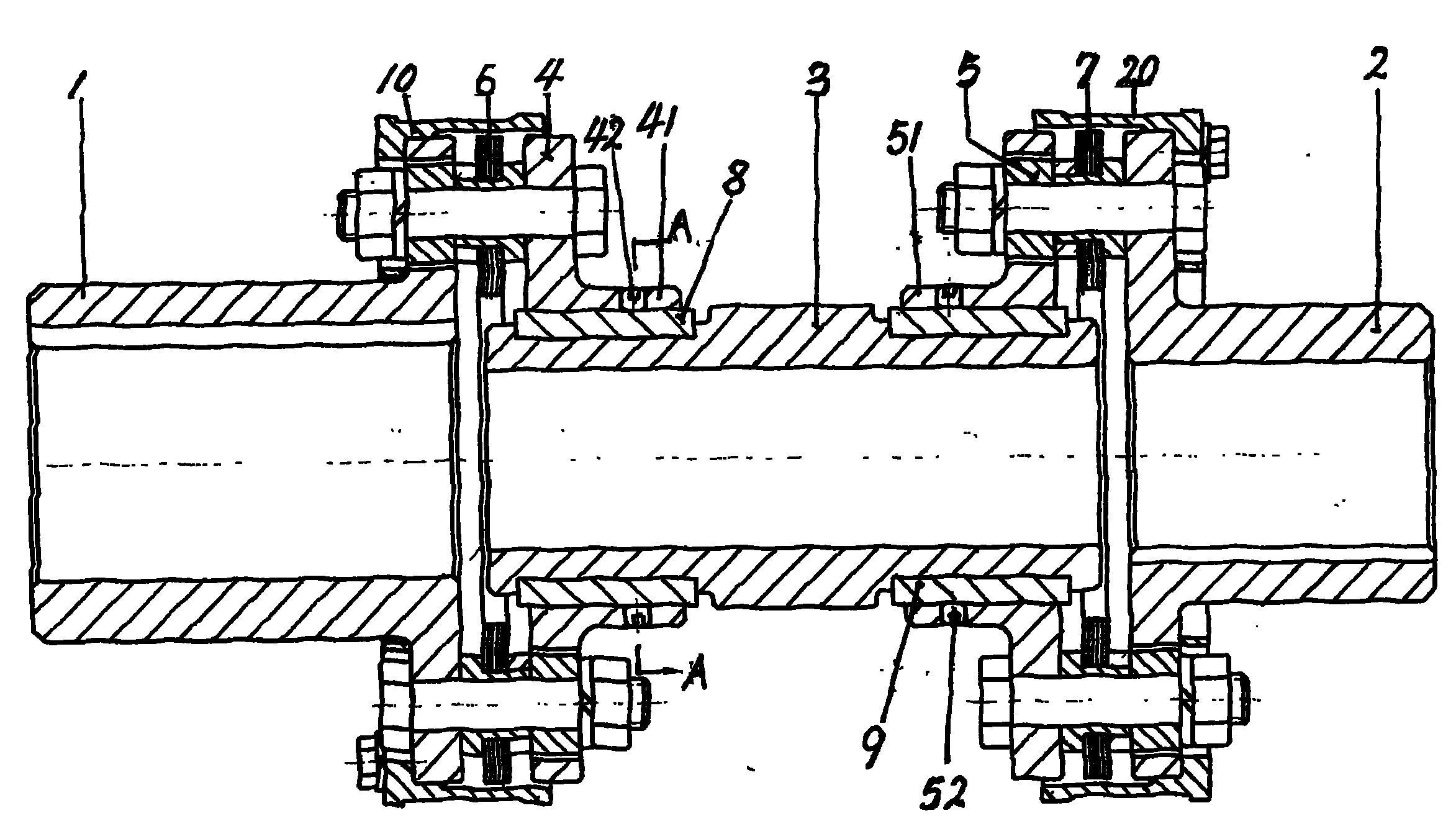

[0012] The present invention consists of driving end half shaft section 1, driven end half shaft section 2, intermediate shaft section 3, driving end intermediate shaft section flange 4, driven and driven end intermediate shaft section flange 5, driving end diaphragm assembly 6, slave The moving end diaphragm assembly 7 is composed of the driving end intermediate shaft joint flange 4 and the driven driven end intermediate shaft joint flange 5 through their bushings 41, 51 to cooperate with the outer circular flat keys at the left and right ends of the intermediate shaft joint 3 respectively.

[0013] The sleeve parts 41 and 51 of the intermediate shaft section flange 4 at the driving end and the intermediate shaft section flange 5 at the driven end are interference fit with the outer circles of the left and right ends of the intermediate shaft section 3 respectively.

[0014] attached figure 1 As shown in the embodiment, the bushings 41, 51 of the intermediate shaft joint flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com