Bar-type material forming and manufacturing device for honeycombed folding curtain fabric

A technology for making devices and strips, which is applied to window decorations, curtains, curtains, etc., can solve the problems of poor neatness of strips, poor quality stability, and imperfect equipment structure, etc. The effect of high production efficiency, high specification and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

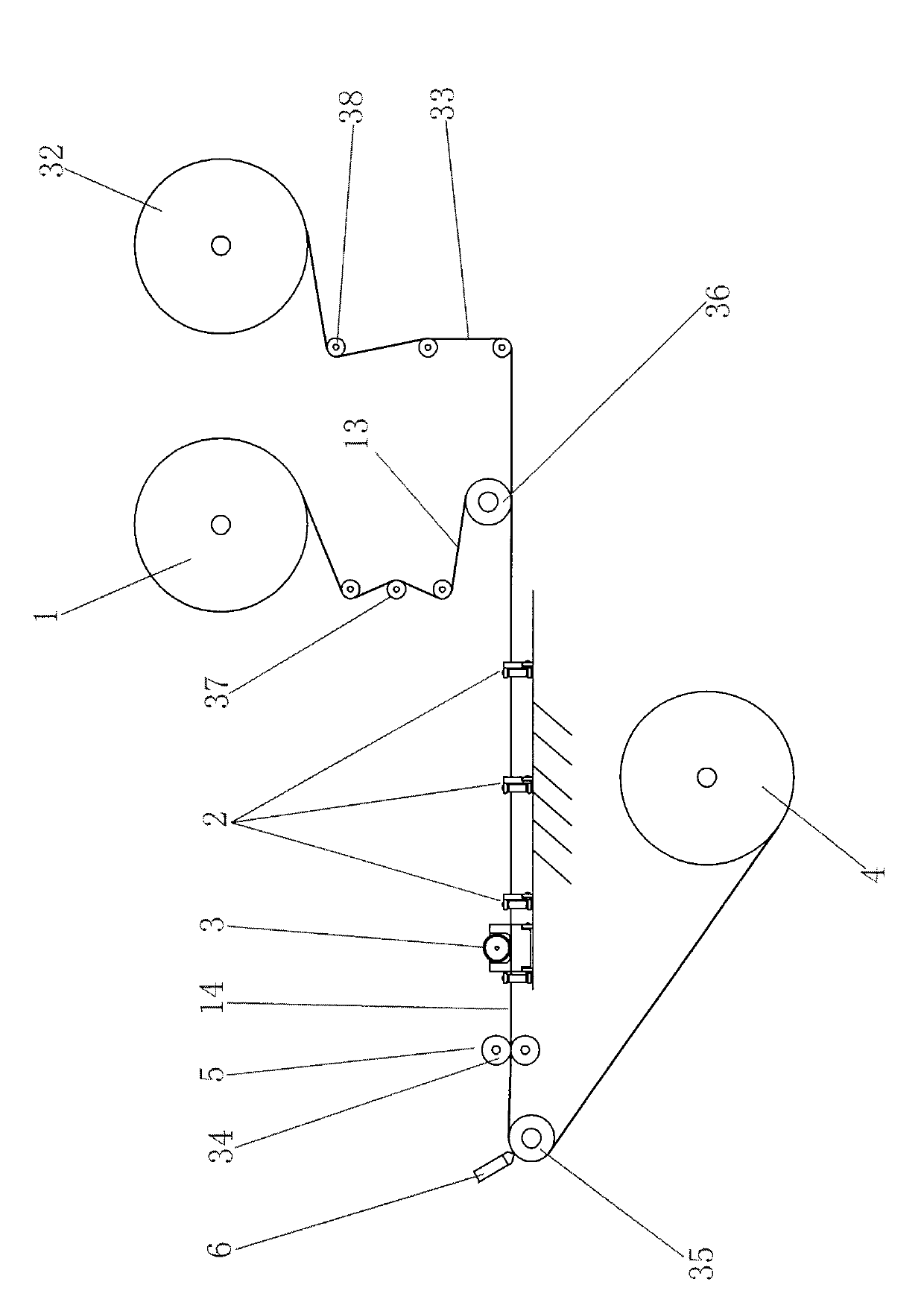

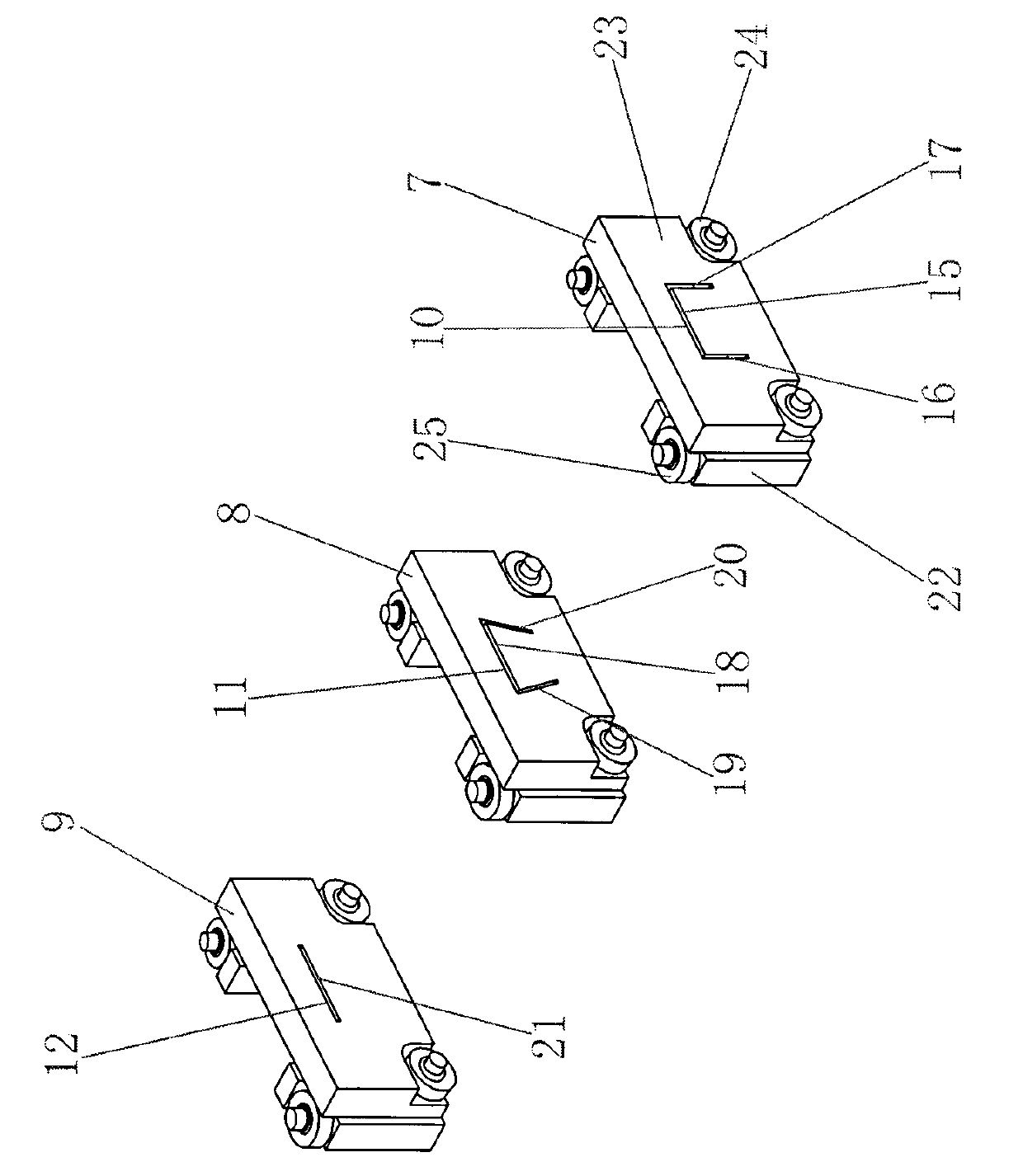

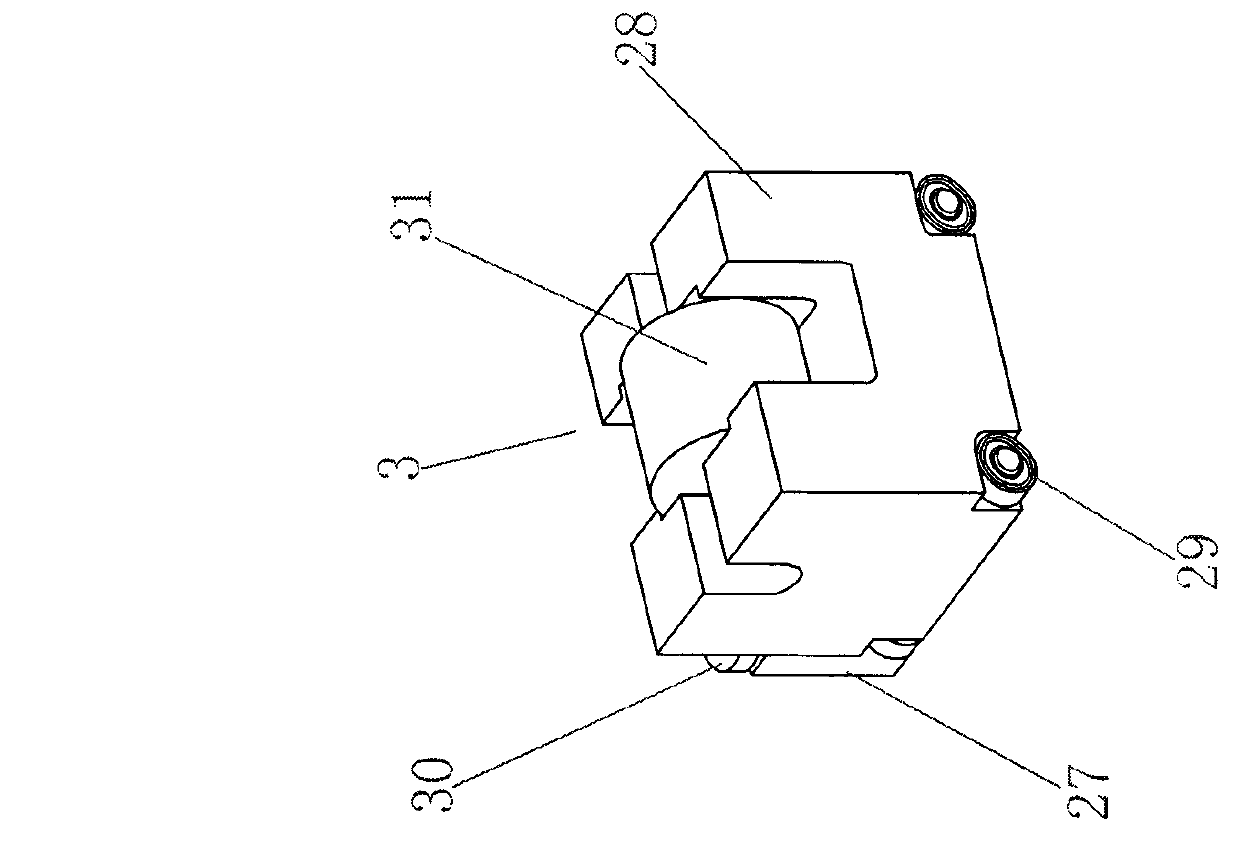

[0026] refer to Figure 1 to Figure 5 , the strip-shaped material forming and manufacturing device for the honeycomb folded curtain cloth is characterized in that it includes a frame and an unwinding mechanism 1, a forming mechanism 2, an electric heating setting mechanism 3, and a winding mechanism 4 installed on the frame in sequence. , and the conveying mechanism 5 and the glue applicator 6 arranged between the mechanisms, wherein the forming mechanism 2 is composed of three forming molds 7, 8, and 9 arranged successively on the frame table, and formed by the forming molds 7, 8, and 9 Through the gaps 10, 11, 12, the two sides of the sheet material belt 13 in transport are led to be bent, and then the bent part is led to be folded. The electric heating setting mechanism 3 is arranged behind the last molding die 9, and the two sides are folded. The sheet material belt 13 is heated and shaped into a strip 14, and the glue applicator 6 is arranged on the transport path of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com