Preparation method of olivine type phosphate positive electrode material for lithium ion battery

A lithium-ion battery, olivine-type technology, applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of lack of commercial application, low electronic conductivity, dependence on modification effect, etc., to achieve good electrical Chemical performance, high reactivity, perfect crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the olivine type phosphate cathode material for lithium ion batteries, its specific steps are as follows:

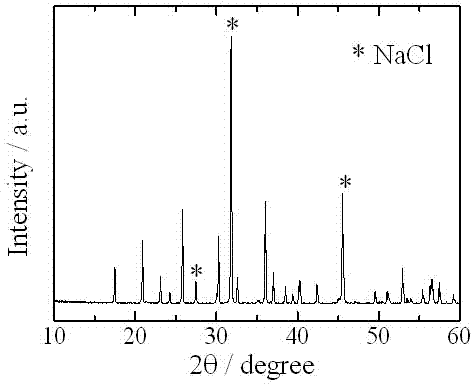

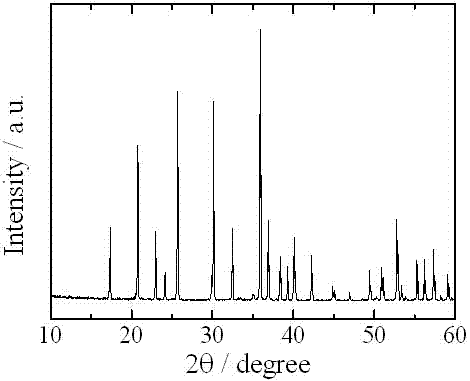

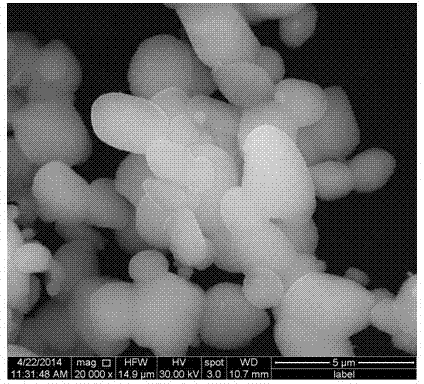

[0025] (1) At room temperature, the LiCoPO obtained by preparing solid powders of metal salt, lithium source and phosphorus source as required 4 The stoichiometric ratio in (i.e. the molar ratio Li:Co:PO 4 =1:1:1) Mix well to obtain a mixture, then add alkali solid powder and carry out ball milling for 2 hours to make the metal salt and alkali undergo a solid-state reaction at room temperature, and finally obtain the precursor after drying at 100°C for 10 hours, in which the metal salt The molar ratio of metal ions to alkali solid powder is 1:2, the alkali solid powder is sodium hydroxide, the metal salt is cobalt chloride, lithium dihydrogen phosphate is both lithium source and phosphorus source, and cobalt chloride and sodium hydroxide are generated at room temperature Solid phase reaction to generate cobalt hydroxide and molten salt m...

Embodiment 2

[0031] The preparation method of the olivine type phosphate cathode material for lithium ion batteries, its specific steps are as follows:

[0032] (1) At room temperature, the metal salt, lithium source and phosphorus source solid powder were prepared according to the required phosphate LiCoPO 4 The stoichiometric ratio of / C (i.e. the molar ratio Li:Co:PO 4 =1:1:1) Mix well to obtain a mixture, then add alkali solid powder and carry out ball milling for 2 hours to make the metal salt and alkali undergo a solid-state reaction at room temperature, and finally obtain a precursor after drying at 120°C for 10 hours, in which the metal in the metal salt The molar ratio of ions to alkali solid powder is 1:2, the alkali solid powder is potassium hydroxide, the metal salt is cobalt sulfate and cobalt acetate with a molar ratio of 1:1, lithium dihydrogen phosphate is both lithium source and phosphorus source, cobalt sulfate Solid phase reaction at room temperature with cobalt acetate...

Embodiment 3

[0037] The preparation method of the olivine type phosphate cathode material for lithium ion batteries, its specific steps are as follows:

[0038] (1) At room temperature, the solid powder of metal salt, lithium source and phosphorus source was pressed by phosphate LiCoPO 4 The stoichiometric ratio of / C (i.e. the molar ratio Li:Co:PO 4 =1:1:1) Mix well to get the mixture, then add alkali solid powder and carry out ball milling for 4 hours to make the metal salt and alkali undergo a solid phase reaction at room temperature, and finally dry at 80°C for 10 hours to obtain the precursor, in which the metal in the metal salt The molar ratio of ions to alkali solid powder is 1:1, the alkali solid powder is calcium hydroxide, the metal salt is manganese chloride, lithium dihydrogen phosphate is both lithium source and phosphorus source, manganese chloride and calcium hydroxide are solidified at room temperature The opposite reaction generates manganese hydroxide and molten salt me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com