Torsion target type flowmeter

A target flow and torsion technology, applied in the direction of volume/mass flow generated by mechanical effects, through detection of dynamic effects of fluid flow, etc. High temperature performance requirements and other issues, to achieve the effect of improving application ability and application range, good structure, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

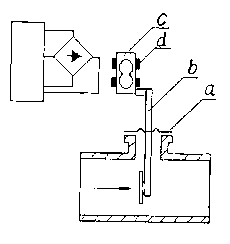

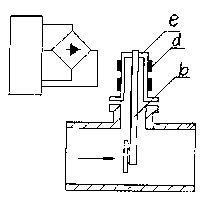

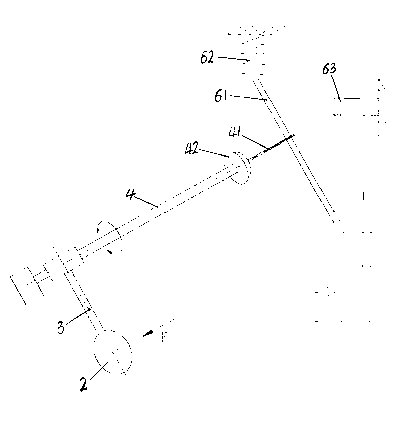

[0022] The present invention includes a measuring tube 1, a target piece 2, a target rod 3, a target rod sleeve 30, a torque tube 4, a torque mandrel 41, a support ring 42, a torque tube sleeve 5, a torsion bar pressure sensing mechanism 6, a torque Rod pressure sensing mechanism chamber shell 7, meter head 9, target piece 2 is fixedly installed on the lower end of target rod 3 and placed in the center of measuring tube 1, and the upper and lower ends of target rod sleeve 30 are respectively connected with torque tube sleeve 5 and measuring tube 1 fixed connect, The upper end of the target rod 3 is fixedly connected with the left end of the torsion tube 4, the torsion mandrel 41 is fitted in the torsion tube 4 through gap fit, the left end of the torsion tube 4 is welded and fixedly connected to the torsion mandrel 41, the inner ring of the support ring 42 is connected to the torsion tube The right end of 4 is welded and sealed and fixedly connected, the outer ring of the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com