ABS (antilock brake system)/ASR (acceleration slip regulation) comprehensive testing system for low friction vehicle

A comprehensive test and automobile technology, applied in the field of comprehensive test, can solve the problems of serious slipping between wheels and drums, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

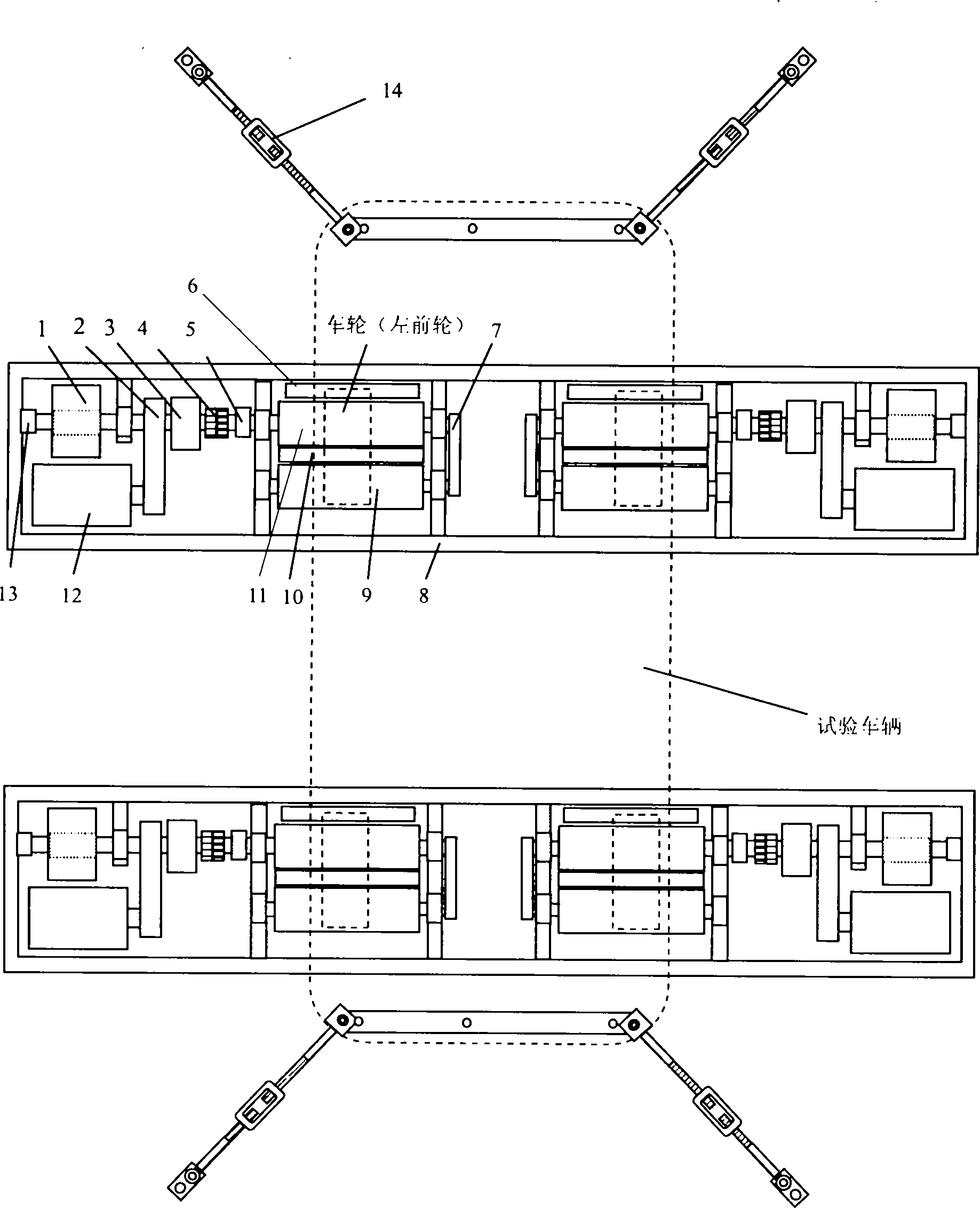

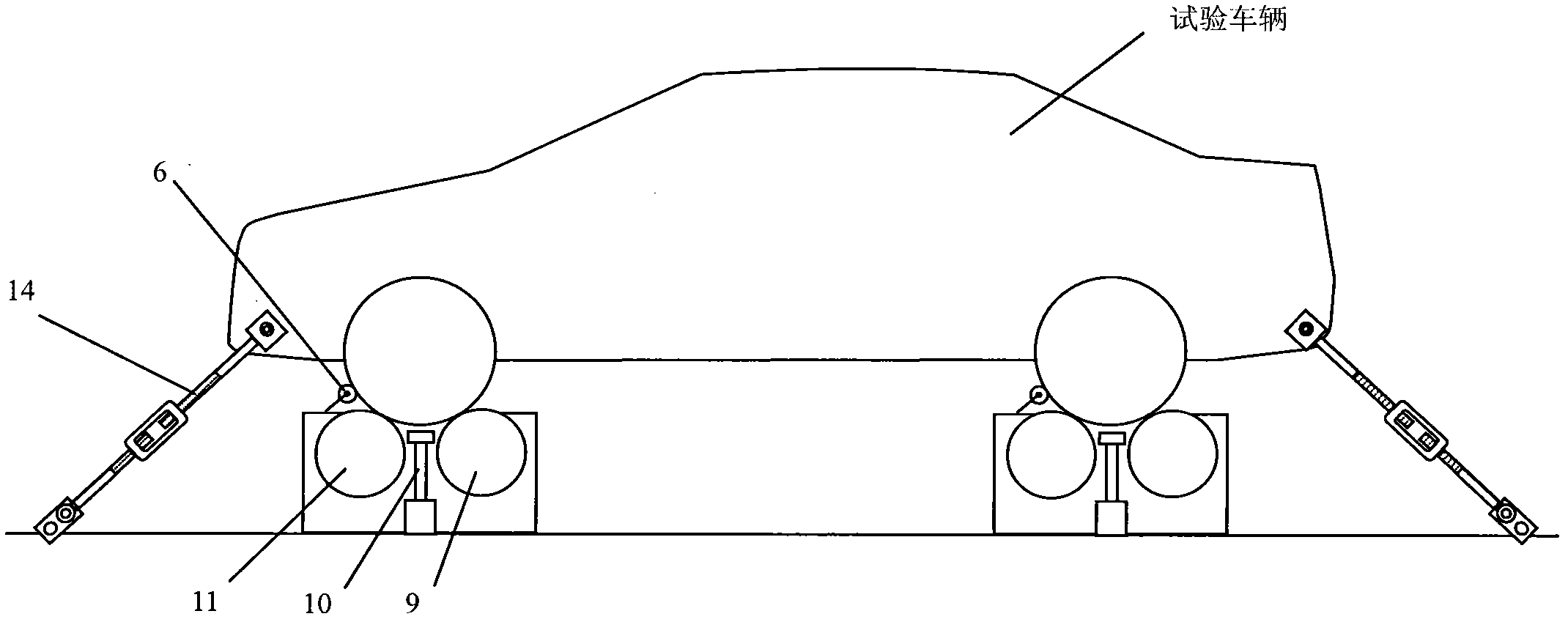

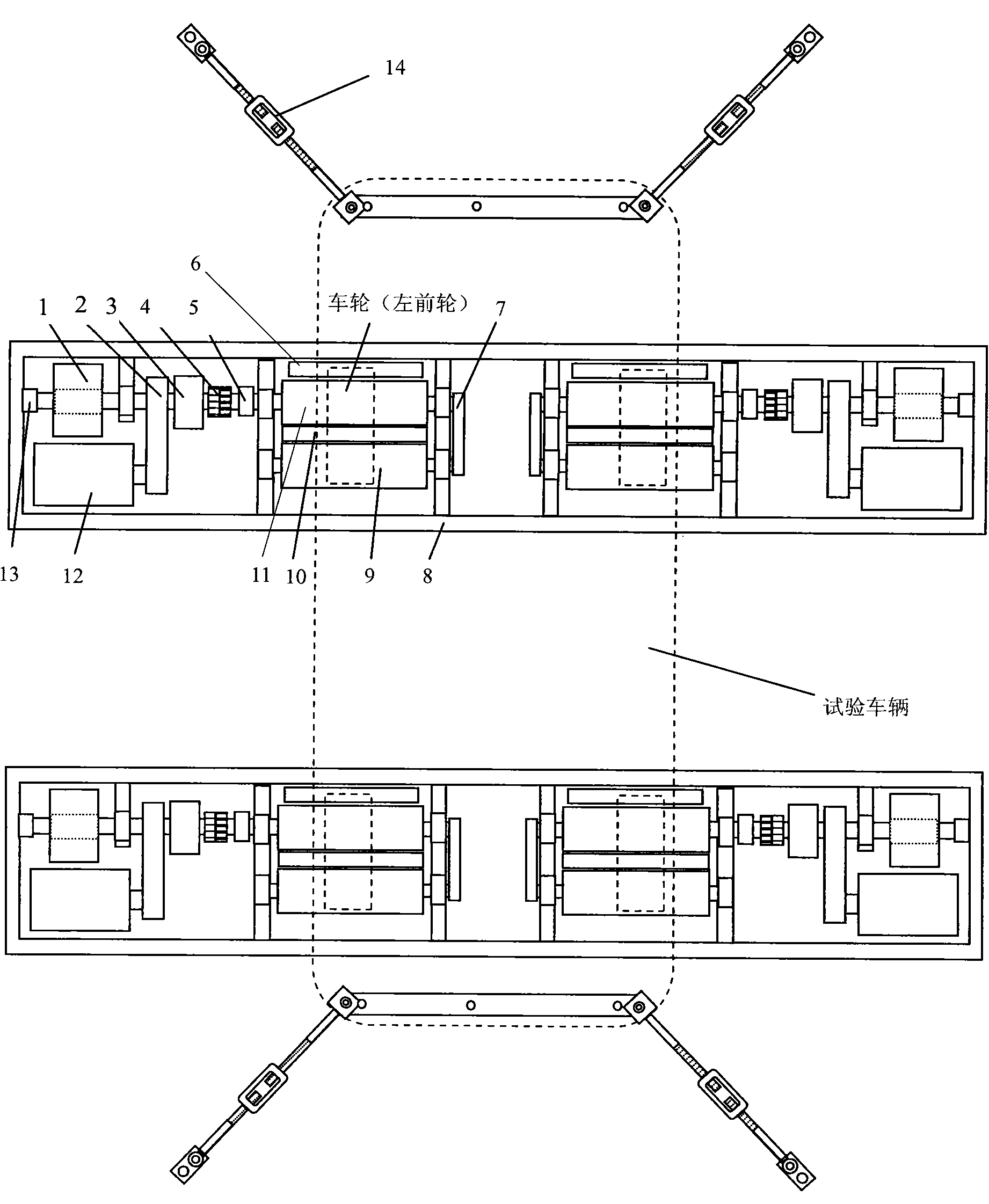

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] The low-slip automobile ABS / ASR comprehensive test system is composed of front and rear axle test benches with the same structure; the front and rear axle test benches are respectively composed of two left and right wheel test benches with the same function and symmetrical structure. The bench can be controlled independently; as shown in the figure, it is the test bench for the left front wheel (the test benches for the other three wheels have the same composition), which consists of a flywheel (1) brake-driven transmission device (2), slip torque control device (3) , shaft coupling (4), torque speed sensor (5), third drum (6), front and rear drum transmission device (7), frame (8), rear drum (9), drum brake Lifting platform and weighing platform (10), front drum (11), brake driving device (12), flywheel speed sensor (13) and vehicle fixed loading device (14)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com