Water-cooled automatic control system of heavy-duty equipment

An automatic control system and equipment technology, applied in the general control system, control/regulation system, program control, etc., can solve problems such as failure to monitor whether there is an interruption, damage to heavy-duty equipment, economic loss, etc., to achieve convenient man-machine Comprehensive effect of interaction and monitoring results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

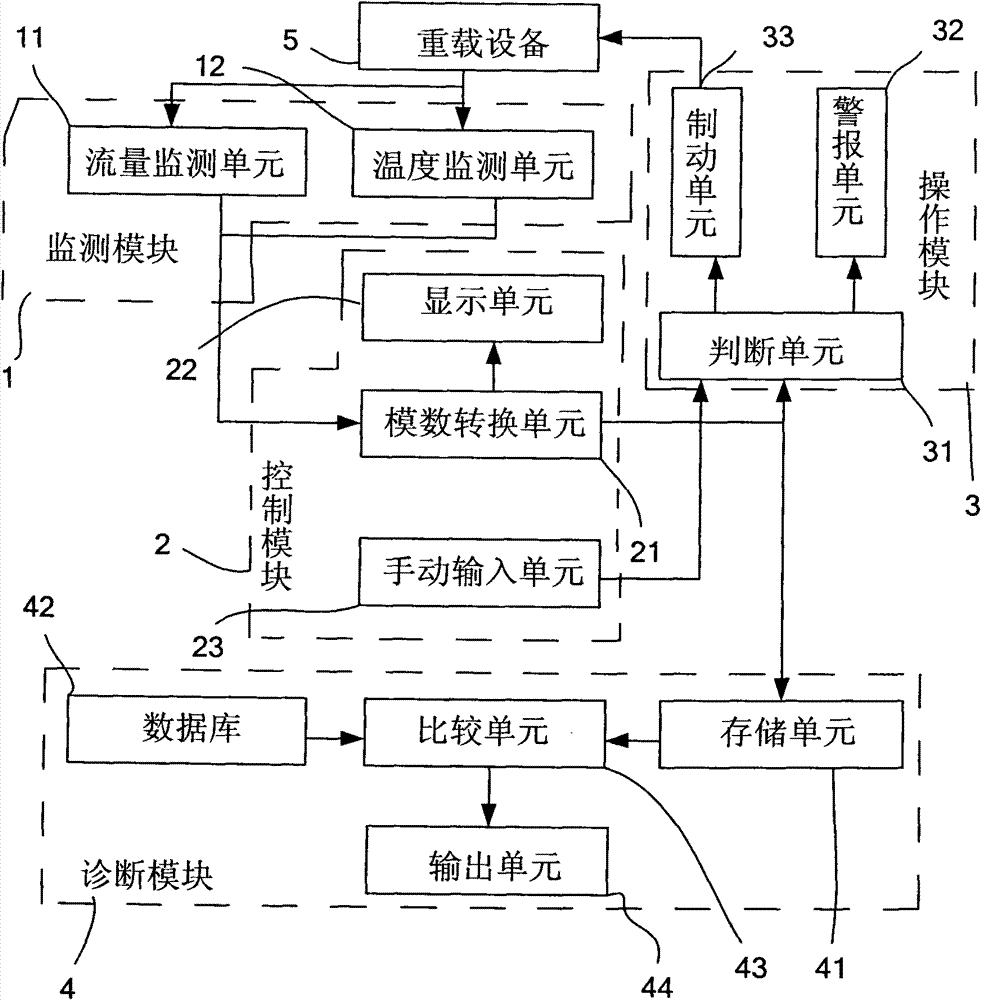

[0033] like figure 1 As shown, the present invention includes: a monitoring module 1, a control module 2, an operating module 3 and a diagnostic module 4, wherein: the monitoring module 1 monitors the water-cooling operation status of the heavy-duty equipment 5, and sends the status information to the control module 2; the control module 2 After receiving the status information sent by the monitoring module 1, convert it, and send the converted information to the operation module 3 and the diagnosis module 4 respectively; after receiving the information sent by the control module 2, the operation module 3 makes a judgment, Operate the heavy load device 5 according to the judgment result; after receiving the information sent by the control module 2 , the diagnostic module 4 performs storage comparison and judges the running state of the heavy load device 5 .

[0034] The water cooling system of the heavy-duty equipment 5 in the present invention includes multiple heavy-duty equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com