Stepping motor controller

A stepper motor and controller technology, applied in the direction of motor generator control, control system, electrical components, etc., can solve the problems of large equipment, inconvenient transportation, inconvenient operation of stepper motor testing, diagnosis, demonstration, etc. Achieve the effect of precise control and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

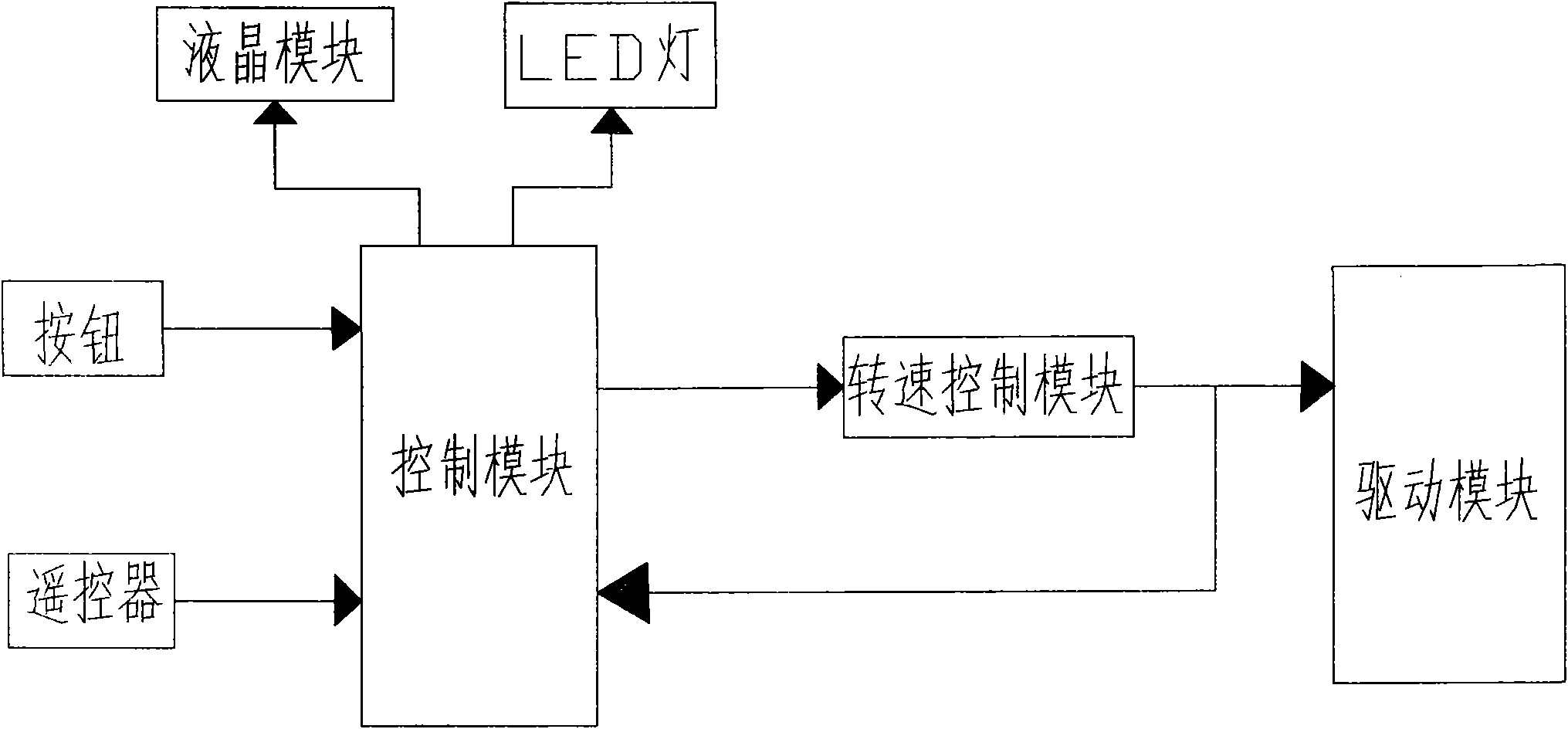

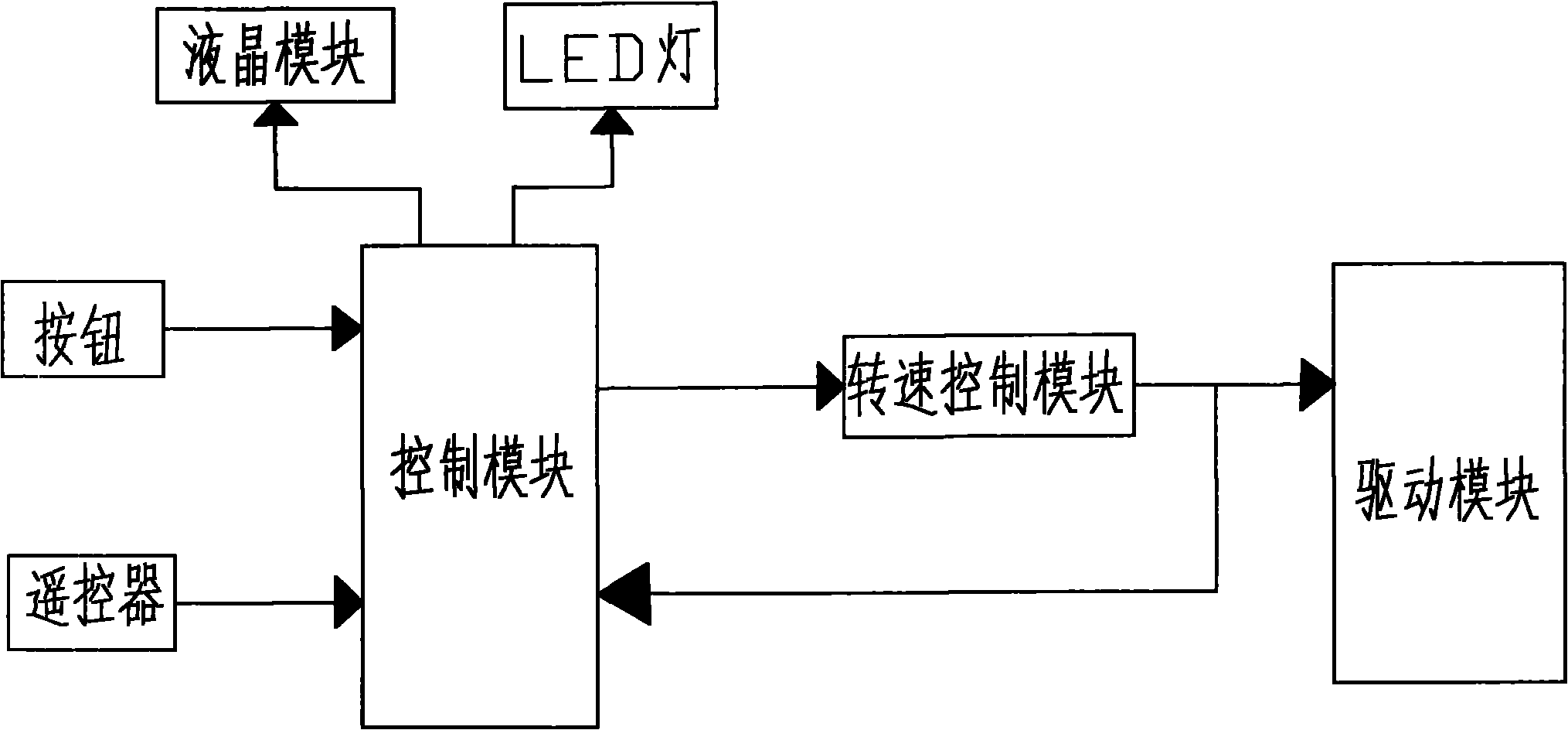

[0014] See attached figure 1 , a stepper motor controller comprising

[0015] Voltage conversion module (not shown in the figure), the power received by the voltage conversion module is a 15V DC power supply, and the voltage conversion module directly transmits the power to the stepper motor to make the stepper motor work; and after the voltage is converted to 3.3V Powers the control module and display module. The power supply received by the voltage conversion module can be in various forms, including DC and AC. The DC voltage of 8V to 25V can directly meet the working needs of the stepper motor without an additional voltage conversion.

[0016] Input module, the input module in the present e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com