Electrically-driven bearing/gear mounting device capable of adjusting height and angle

An installation device and electric drive technology, which is applied in hoisting devices, metal processing, metal processing equipment, etc., can solve problems such as low work efficiency and poor safety performance, and achieve the effects of easy operation, guaranteed stability, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

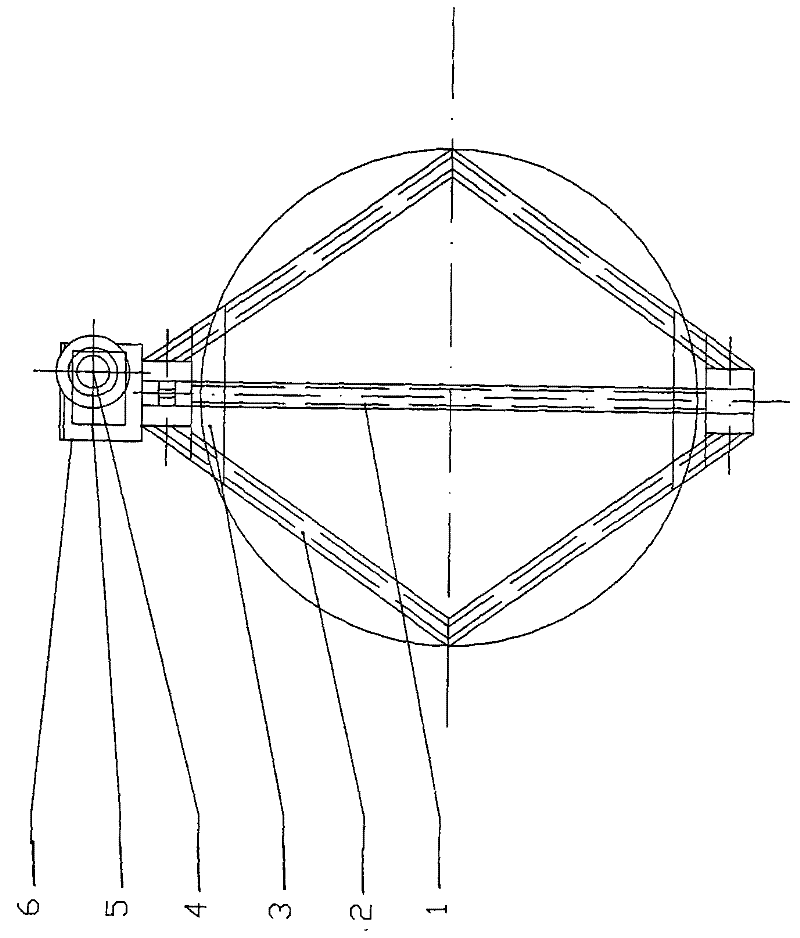

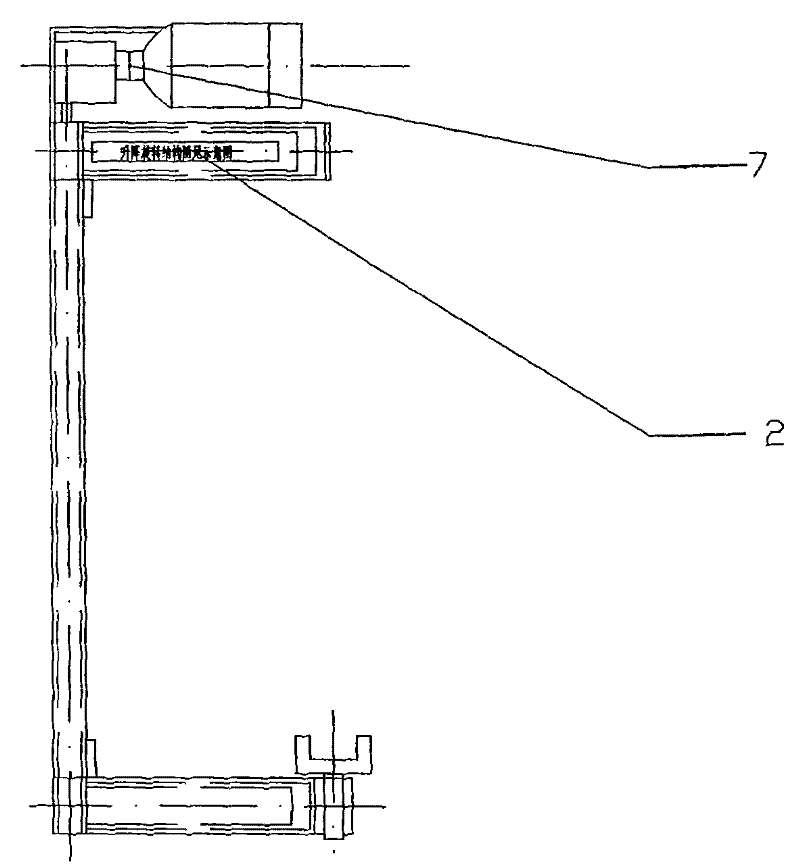

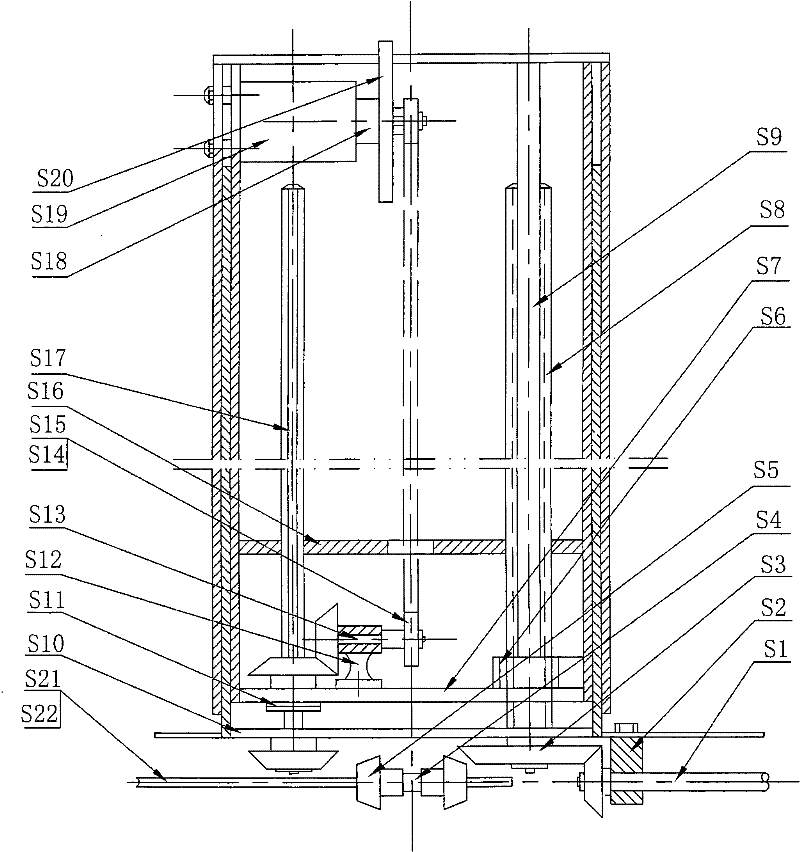

[0017] As shown in the figure: an electrically driven adjustable height and angle bearing / gear installation device, the lifting and rotating device 2 is respectively installed on the top and bottom of the rhombus chassis 1, and the lower part of the rhombus chassis is equipped with a fixed plate S10; the lifting and rotating The device is composed of a transmission mechanism, a rotating mechanism, a lifting mechanism and a bearing clamping device.

[0018] The transmission mechanism is composed of a motor 3 and a worm gear reducer 4 , and the motor and the worm gear reducer are fixed on a support plate 5 and connected by a coupling 6 . The main bevel gear set is installed on the worm shaft of the reducer, and the bevel gear A is installed on the transmission shaft; the two lifting and rotating devices at the top and bottom of the rhombus chassis are connected through the transmission shaft.

[0019] The rotating mechanism is composed of a feed rod, a bevel gear B installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com