Clearance type cross-current liquid-liquid separation device

A gap type, liquid separation technology, applied in the field of source separation, can solve the problems of increased difficulty in treatment, increase in treatment cost, unstable treatment effect, etc., and achieve the effect of reducing water quality load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The interstitial interlaced flow liquid-liquid separation device of the present invention will be further described below in conjunction with the accompanying drawings.

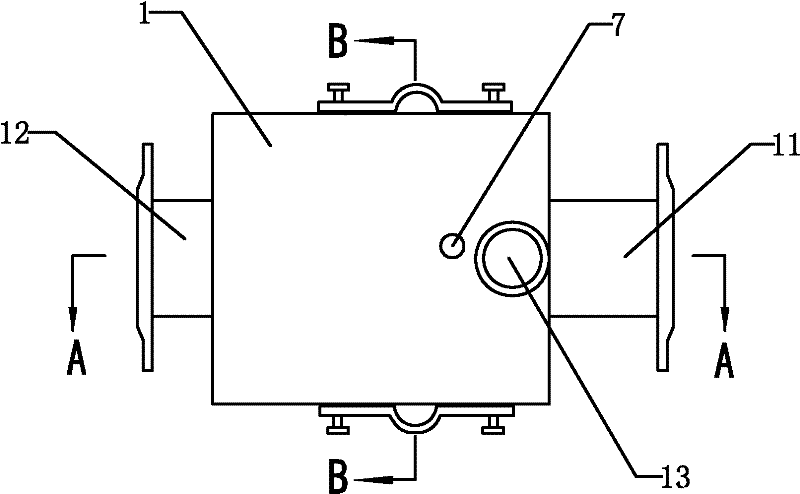

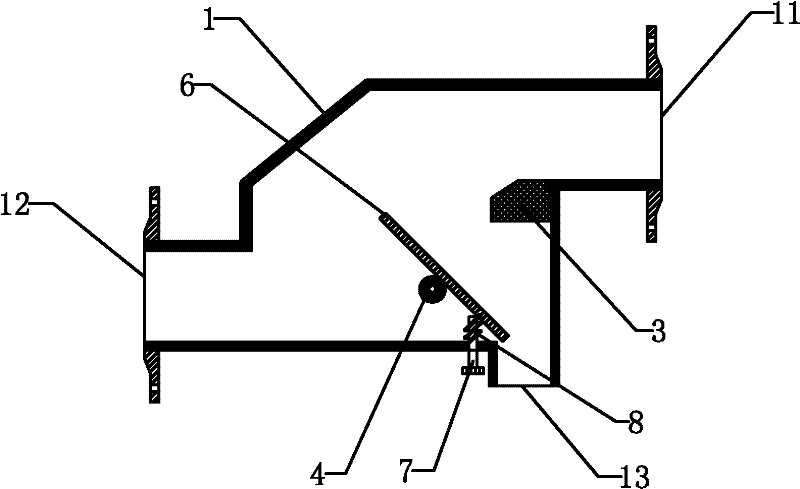

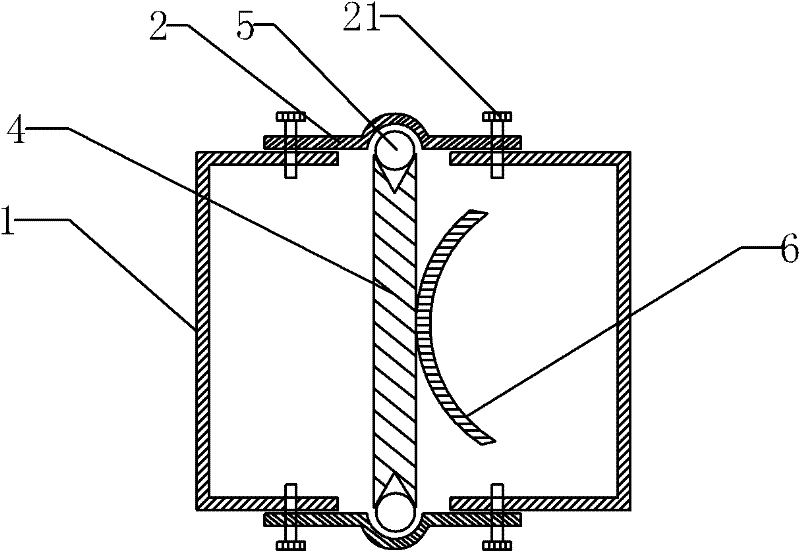

[0015] see figure 1 , figure 2 and image 3 , the gap type interlaced flow liquid-liquid separation device of the present invention comprises a main box body 1, a shaft end cover 2 and an adjustment rod 7, the right rear portion of the main box body 1 is provided with a water inlet nozzle 11, and the main box body 1 A main drain pipe opening 12 is provided on the left front, and a side drain pipe opening 13 is provided on the front side of the main box body 1. The shaft end cover 2 is respectively fixed on the top end surface and the bottom end surface of the main box body 1 by a plurality of end screws 21. On the inside of the main box 1 and at the inner corner of the water inlet 11, a deflector 3 is fixed. Inside the main box 1 and near the side drain 13, a columnar rotating shaft 4 is arranged. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap